What is palletizing (the meaning of palletizing)

What is palletizing (definition)

Palletizing (or palletising, in British English) is the process of of stacking and arranging products onto pallets for convenient, high-volume storage or transport. It has developed along with the development of the forklift and the development of industry in general.

The meaning of Palletizing refers to the method of stacking and arranging products or goods onto pallets for efficient handling and transportation. It is about strategic placement of items, ensuring stability, and utilizing space optimally.

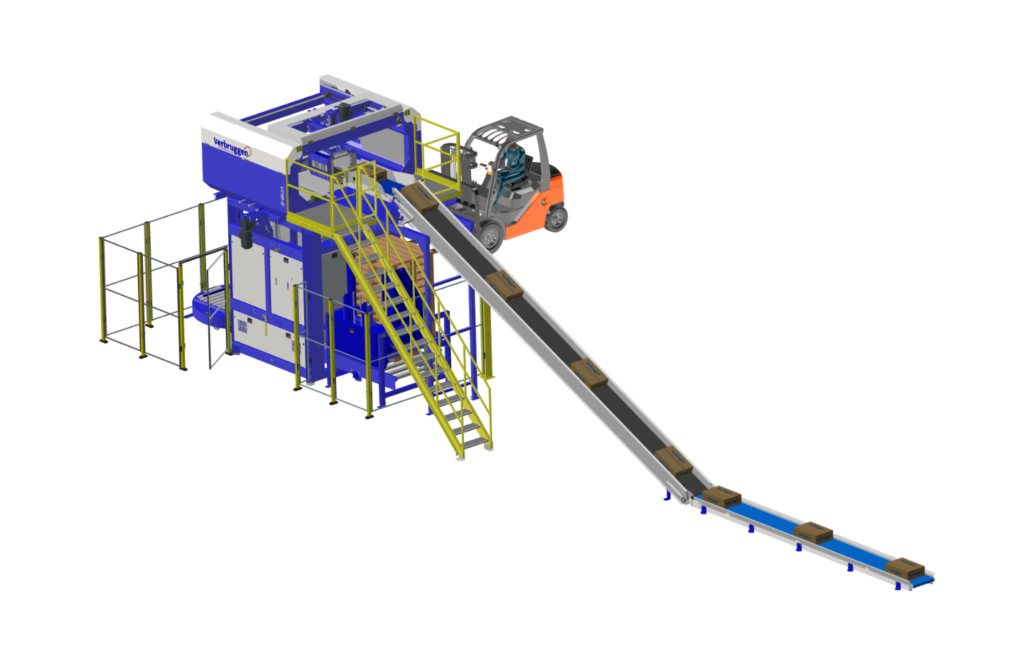

Palletizing can be done manually and automated by a robot or palletizing machine (also palletizer).

Palletizing originally involved manual labor, putting boxes or heavy bags onto pallets for loading into trucks. Nowadays, automated palletizing is great way to improve efficiency, storage capacity, logistics and working conditions.

What is meant by palletizing products?

Palletizing products involves the methodical and secure arrangement of various items on a pallet, enabling effective handling, storage, and transportation of goods. This practice finds extensive application in warehouses, distribution centers, and manufacturing facilities.

Which products can be palletized?

A diverse array of products can be palletized, such as:

- Onions

- Carrots

- Beetroots

- Potatoes

- Coffee and Cocoa

- Salt

- See all products & industries

These products can be palletized using different packaging formats, including:

- Bags

- Boxes

- Crates

- Cartons

- Bags in boxes

By palletizing these items, businesses can benefit from improved logistical operations, streamlined inventory management, and enhanced efficiency throughout the supply chain.

What is pallet packing?

Pallet packing is, in fact, a different word for palletizing, and about the process of arranging and securing goods on a pallet for safe storage and transportation. So, pallet packing involves stacking items to create a stable load, enabling easier handling, maximizing space utilization, and enhancing product protection during transit.

Pallet packing refers strongly to manual stacking of goods on a pallet instead of using a palletizer machine to palletize automatically. Still, pallet packing is a fundamental practice in logistics, optimizing operations and ensuring goods arrive in excellent condition.

Why palletizing?

Palletizing can provide numerous benefits, including increased productivity, improved efficiency, and reduced labor costs. By automating the palletizing process, companies can minimize errors and reduce the risk of product damage during the process.

In addition to these benefits, palletizers can also help optimize storage and transportation processes. The process or method of palletizing allows for the consolidation of multiple items into a single bundle based on volume or weight. Besides providing enhanced product protection, it can also lead to reduced shipping costs.

Clear advantages of automated palletizing products are higher and more stable stacking, more storage space, less product damage, reducing human stacking labor and improving efficiency.

Steps palletizing proces

Here are some essential steps involved:

1. Maximizing box capacity (while stacking boxes or crates)

When packing products into boxes, it is important to fill them to their maximum capacity, taking into account weight or volume limitations. To add an extra layer of protection, individual products can be wrapped before placing them in the boxes. Any empty spaces and corners should be filled to reinforce the boxes and prevent crushing during transportation.

2. Consideration of pallet types

When utilizing an automated palletizer, it is essential to select the appropriate pallet type that matches the system’s specifications. Pallets are available in various materials, such as plastic and wood, and come in different shapes, dimensions, and weights. Consistency in pallet selection is important for maintaining efficiency.

3. Proper product stacking for distribution (while stacking boxes or crates)

All boxes should be stacked with even weight distribution to avoid shifting or toppling of the pallet. It is crucial to ensure that the stacked items do not extend beyond the edges of the pallet, as this could result in damage.

4. Securing with a Wrapping machine

Once the pallet is fully loaded, it should be securely wrapped with multiple layers of plastic wrap to bind the items and pallet together. Additionally, corner protectors made of Styrofoam or cardboard can be added for increased stability if necessary.

How about Palletizing items with unique shapes?

Palletizing items with unique shapes can present additional challenges compared to more uniform products. For instance, industrial equipment is typically strapped to pallets instead of being wrapped.

However, in industries that handle large product volumes, automated palletizers can alleviate manual labor and significantly improve productivity.

Interested in what palletizing can do for your situation?

Discover our different palletizer machines or get in touch for more information. See all contact options at our contactpage (click). We are happy to help you.