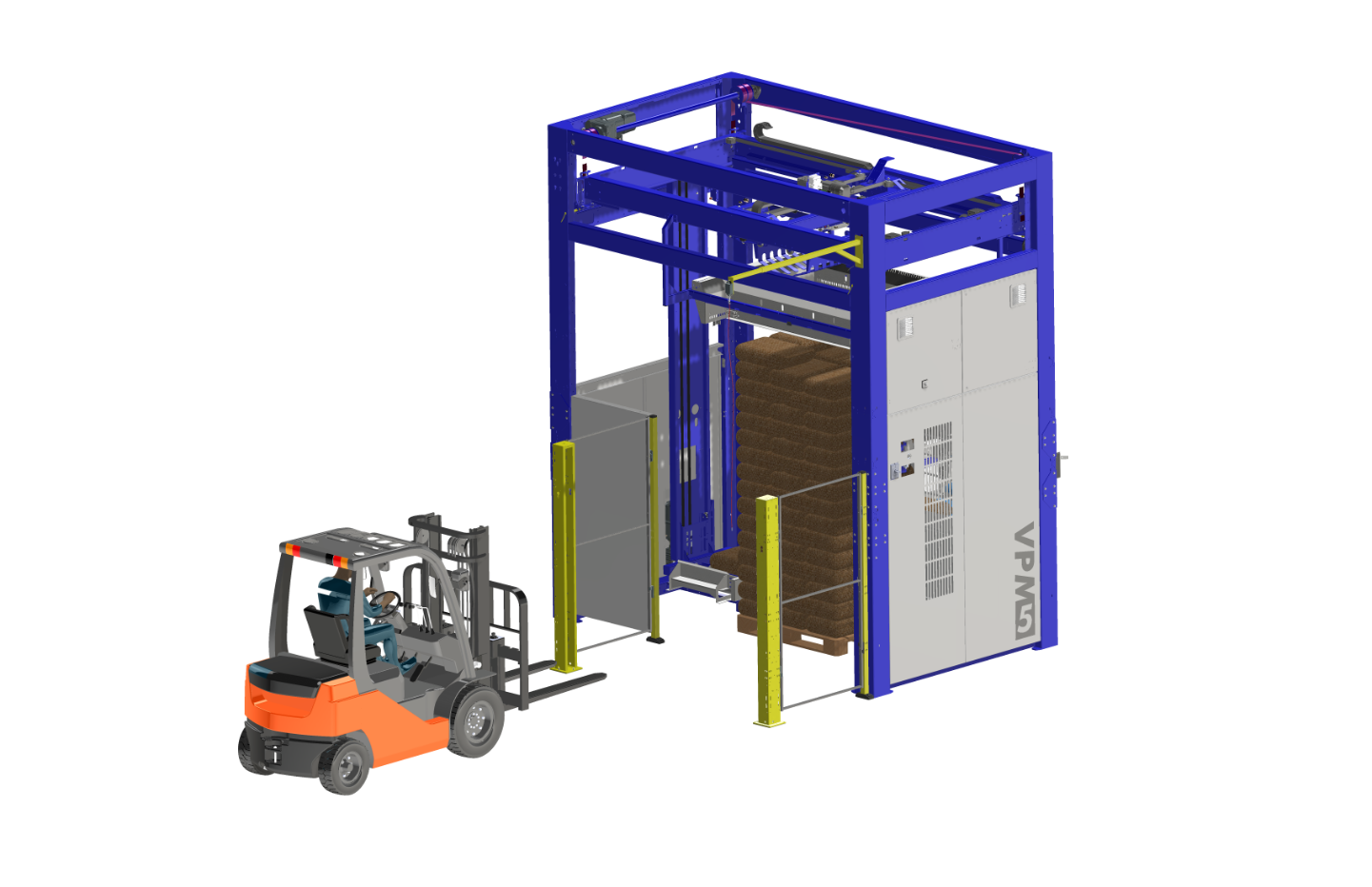

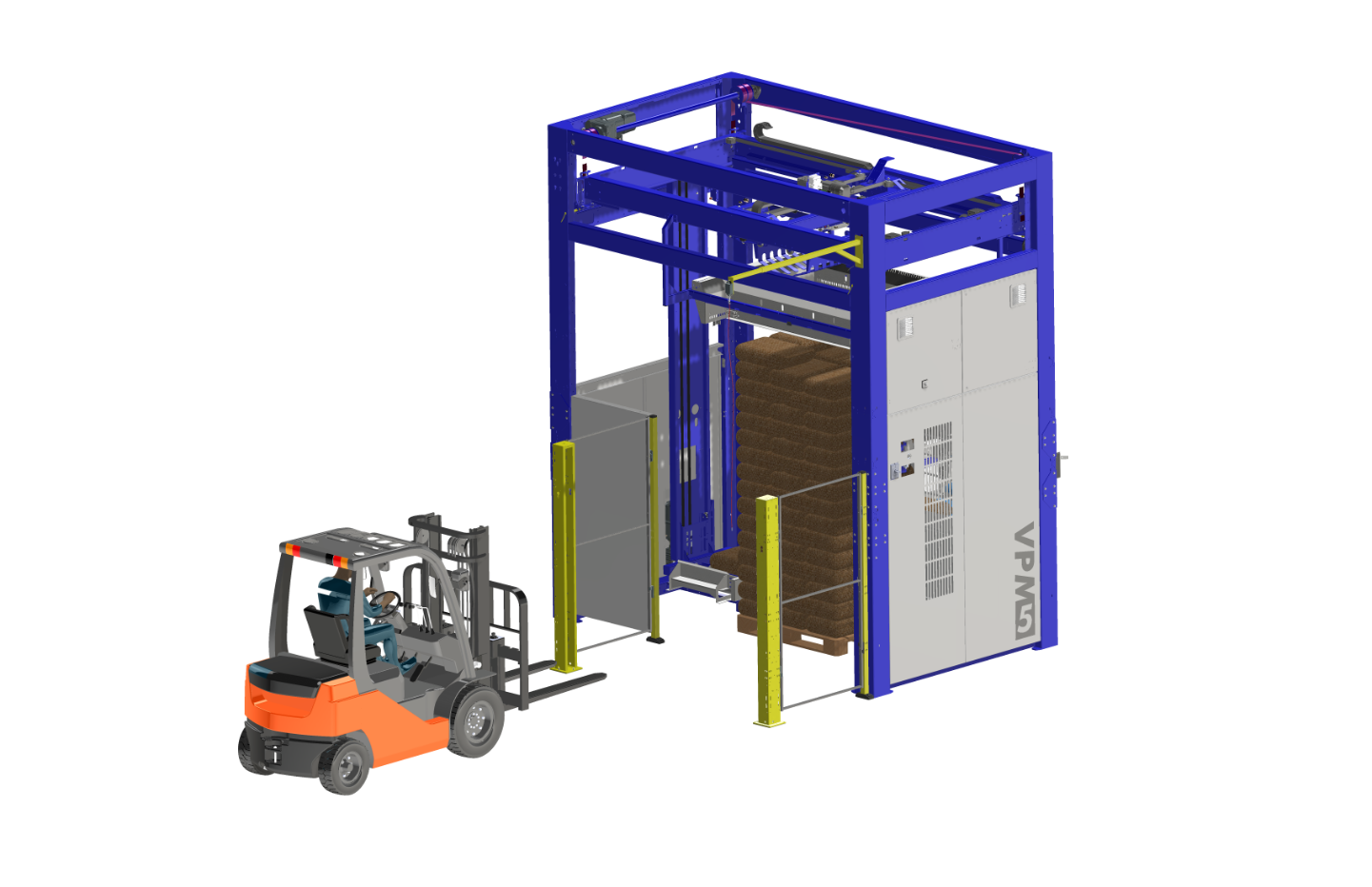

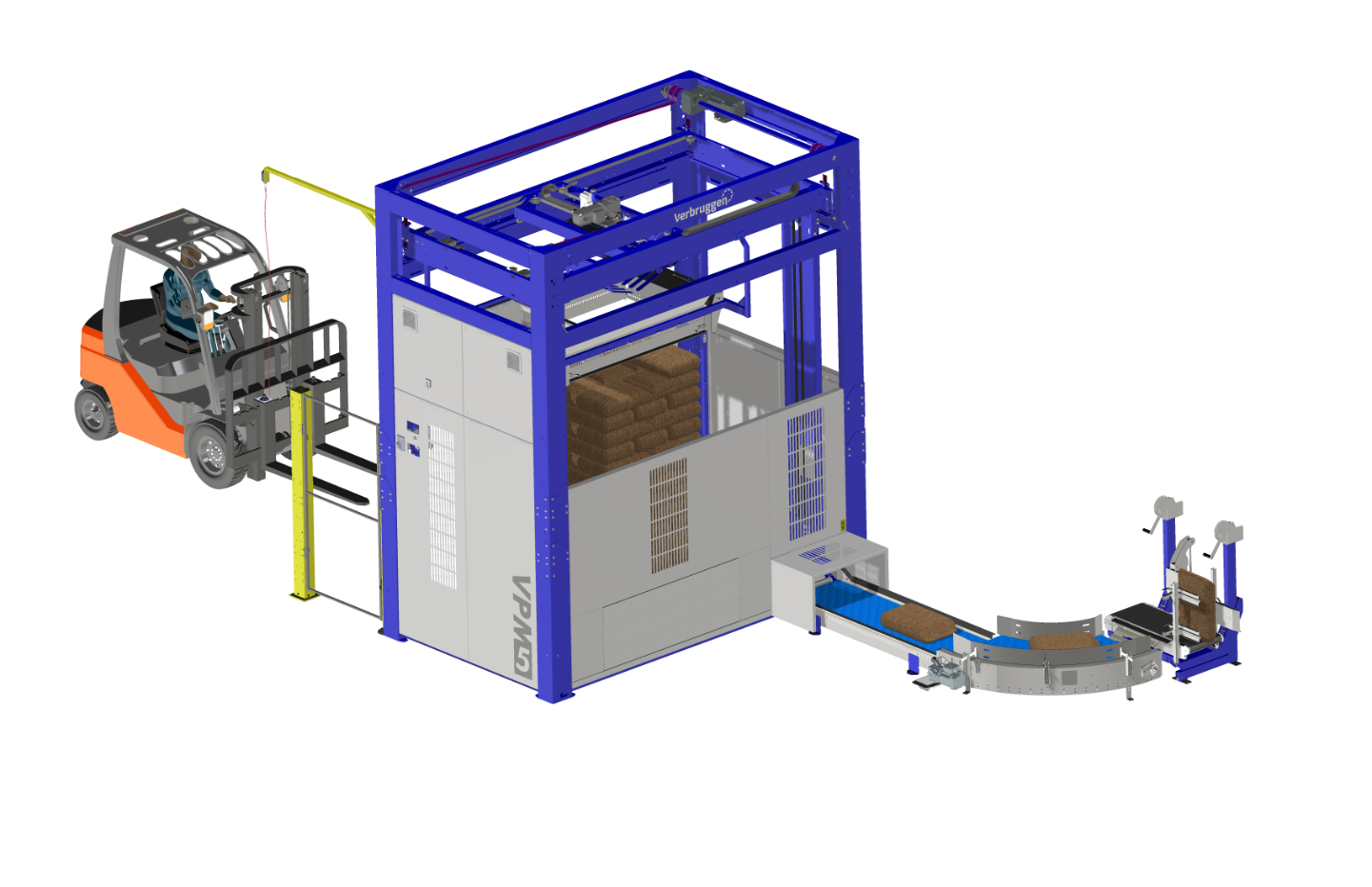

Palletizer VPM-5

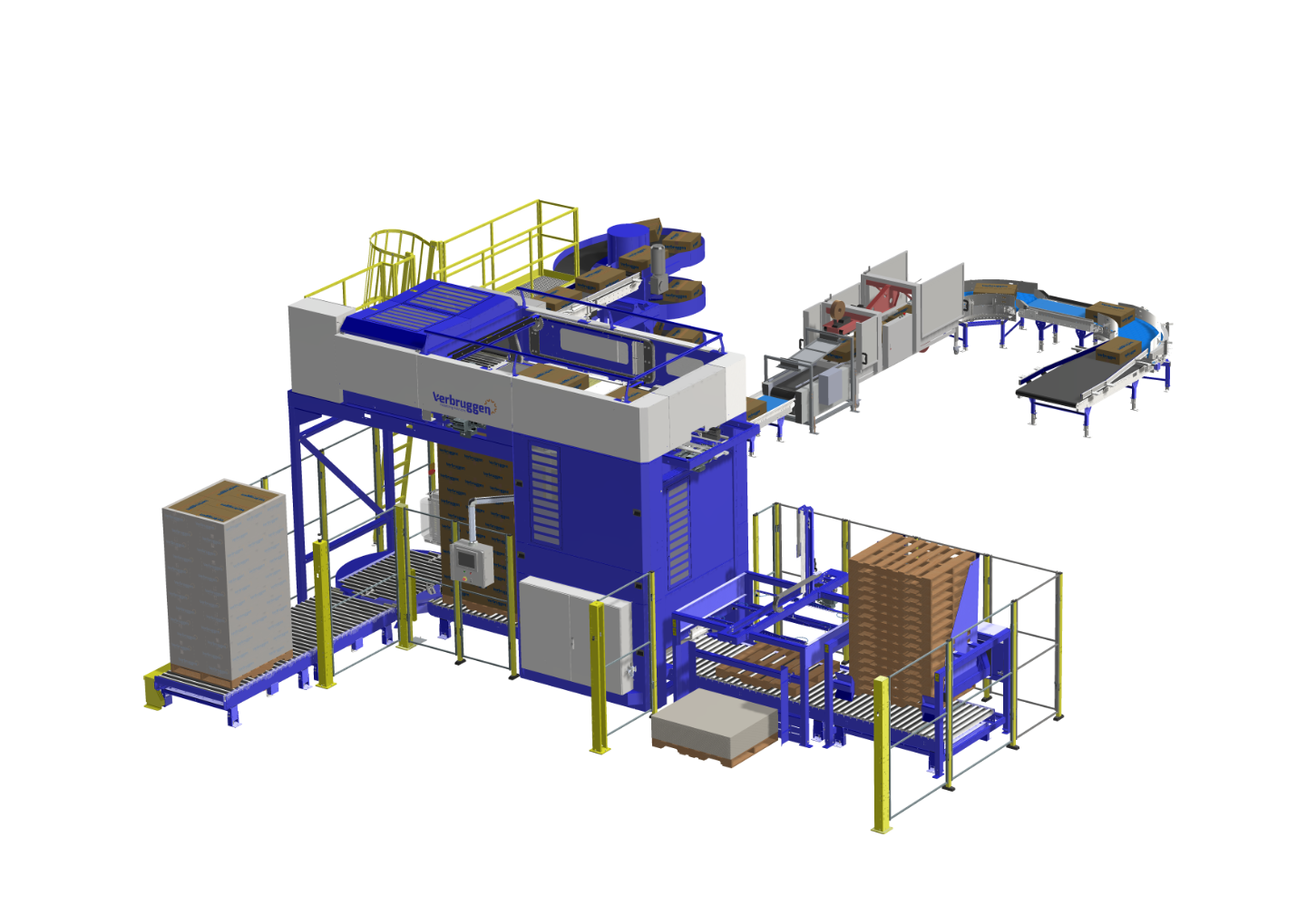

About the Palletizer VPM-5

Looking for an efficient stacking solution while eliminating the need for manual labor? Palletize your products with the innovative technology of the VPM-5. Automated stacking becomes a reality with the accurate and overlapping placement of products by manipulator & formation collar creating consistent and stable pallet loads. This machine is manufactured using the latest in Dutch technical innovation.

Benefits:

- Consistent & stable pallet stacks

- Small equipment footprint

- Low power consumption

- Efficient operation & low maintenance intervals

- High return & short payback period on investment

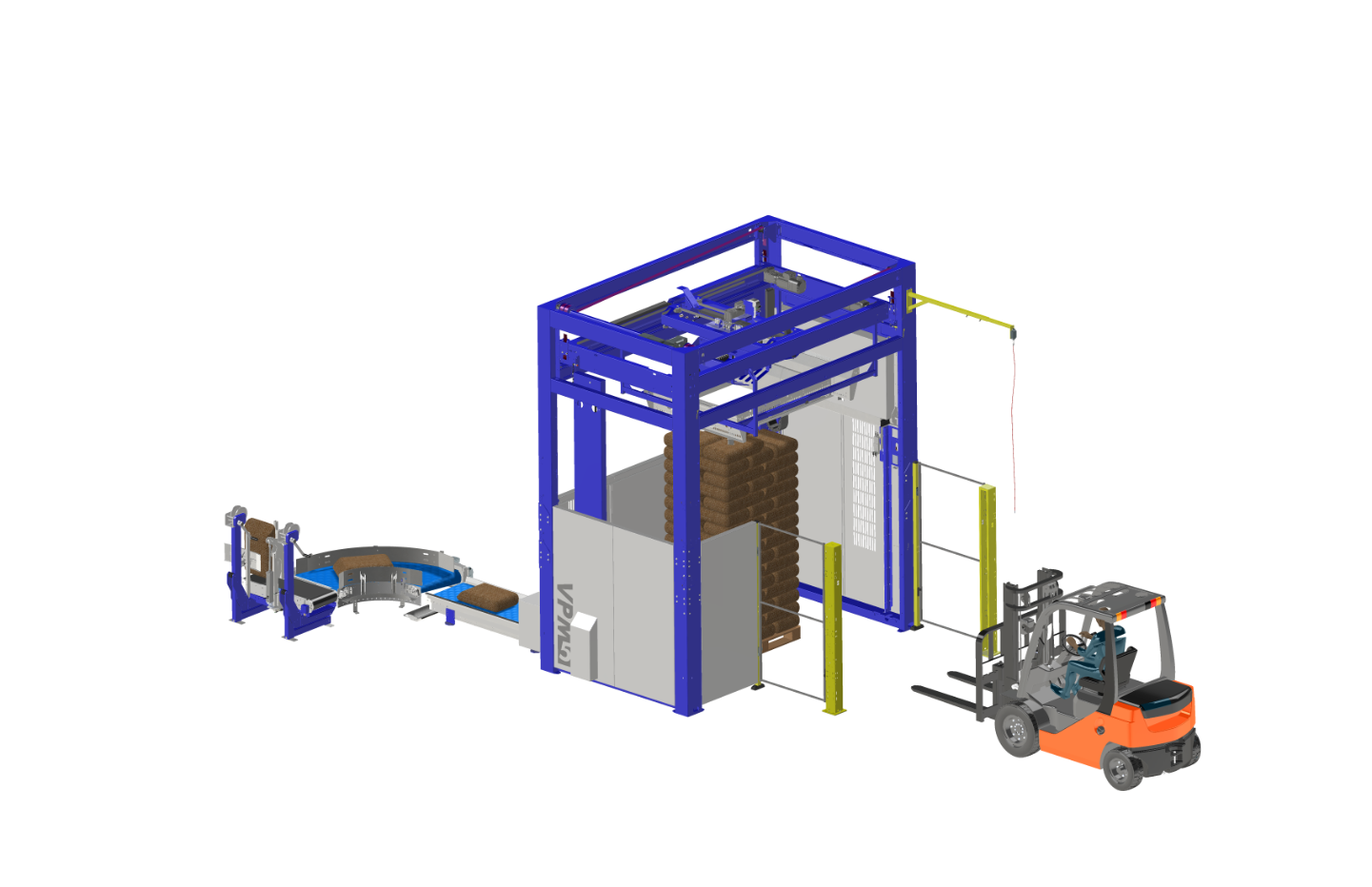

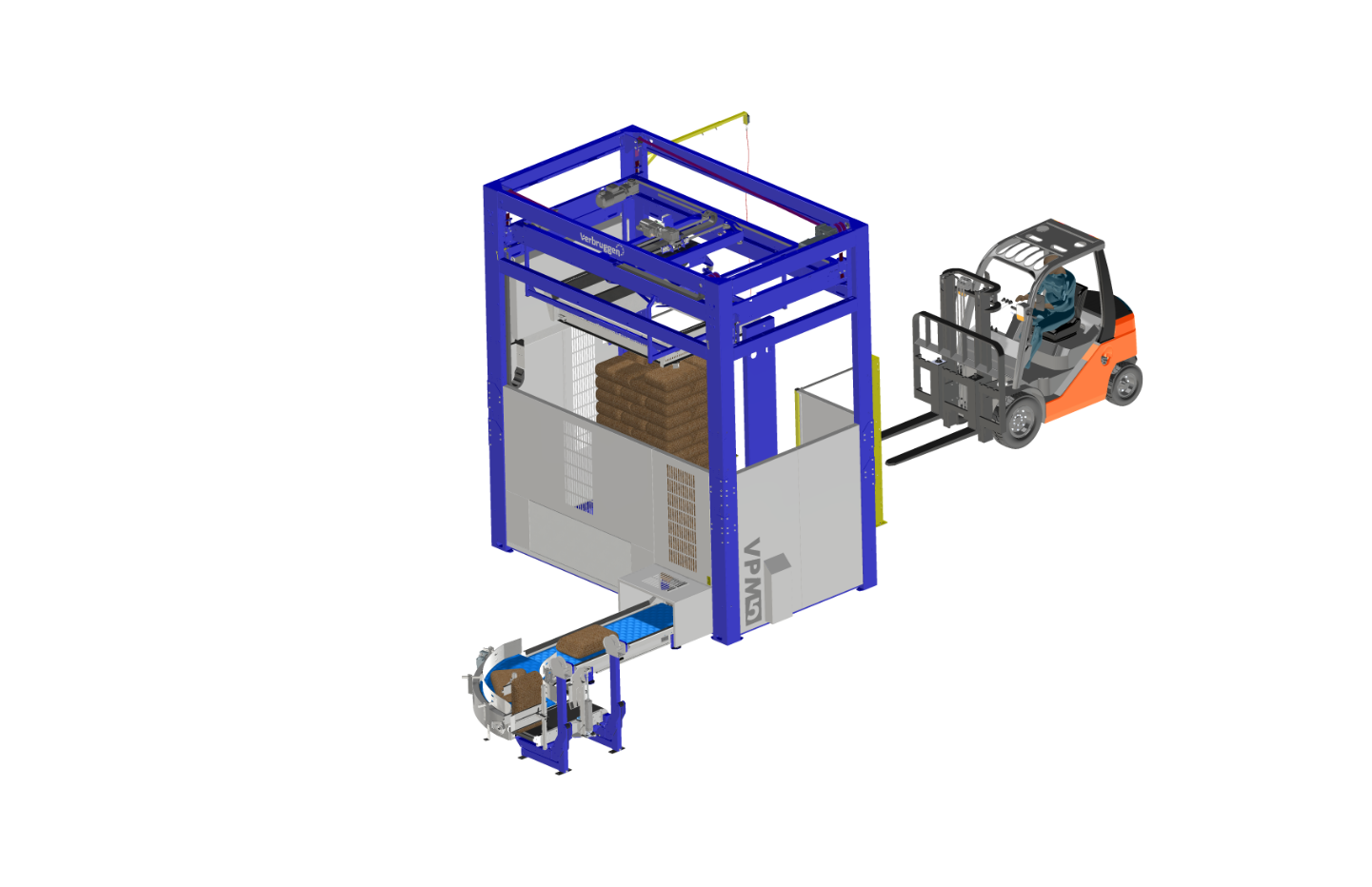

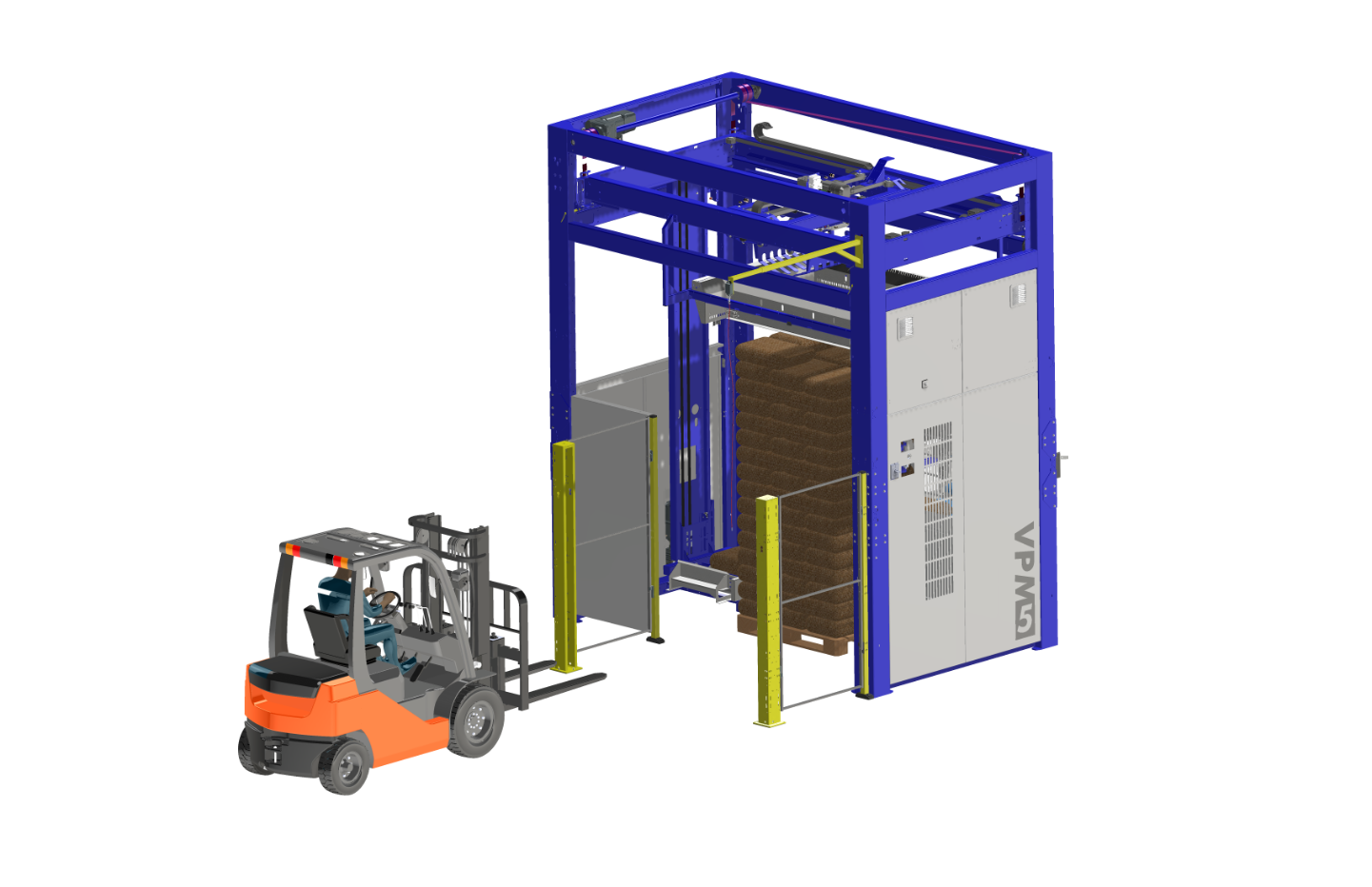

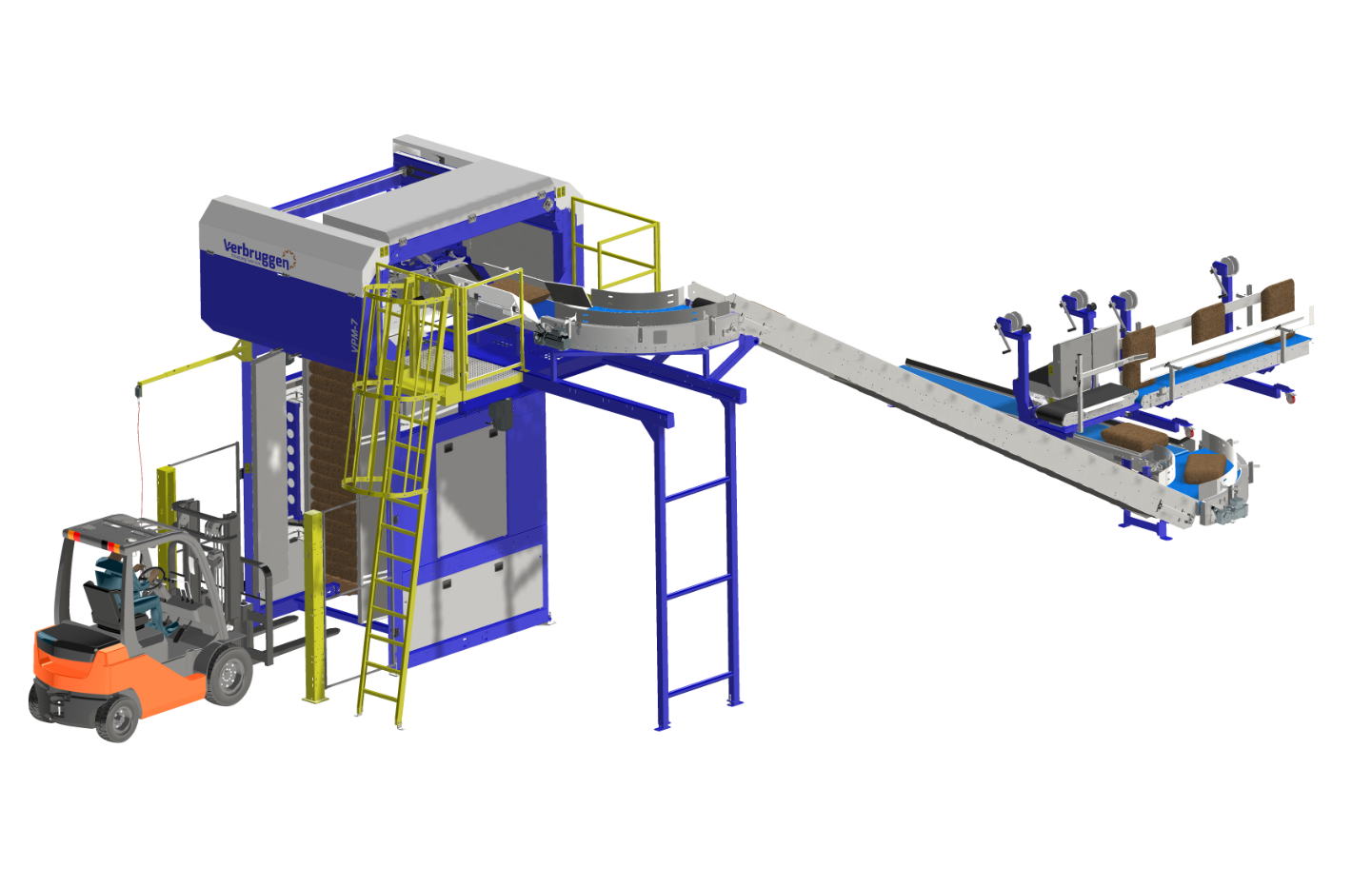

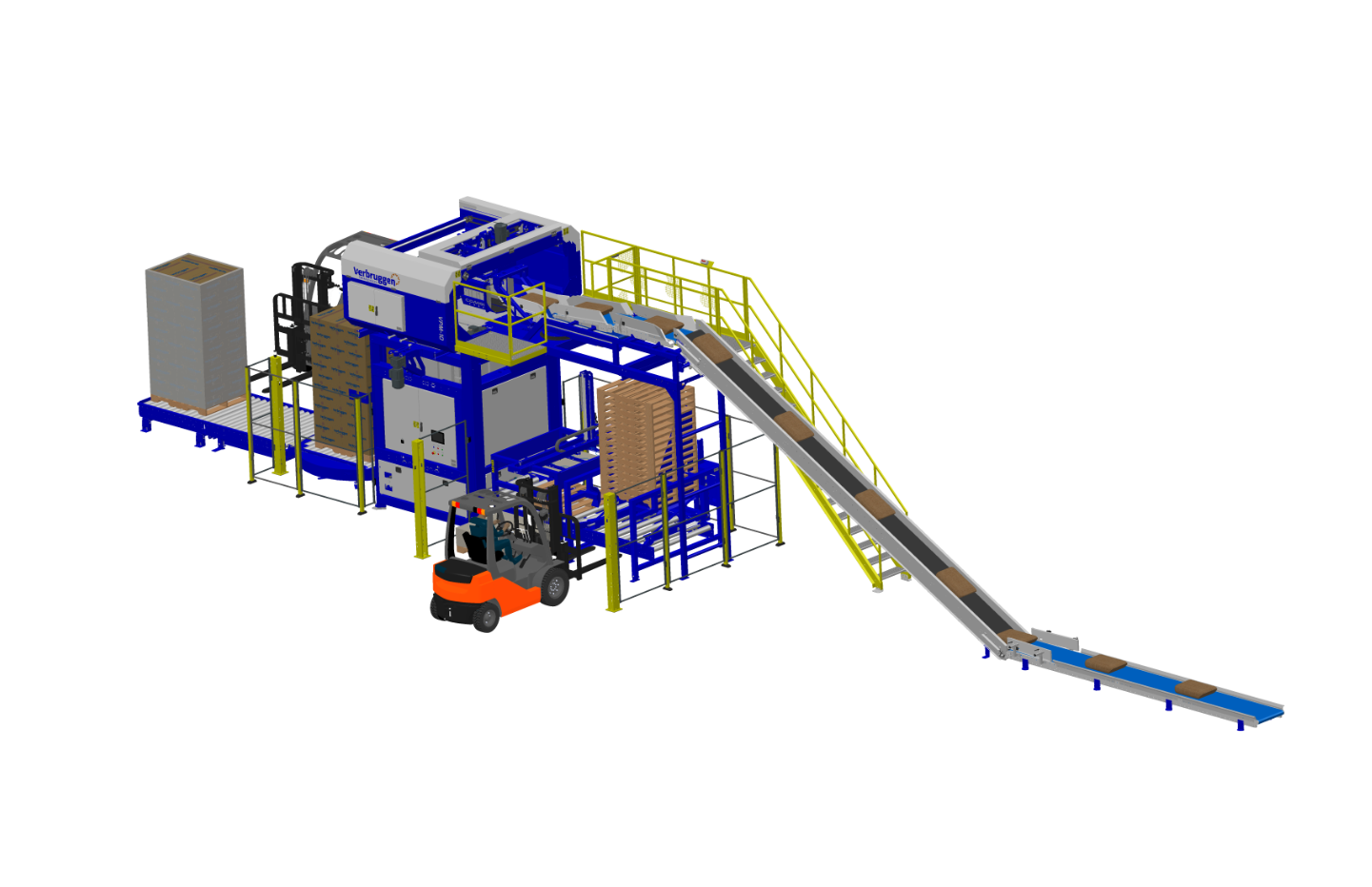

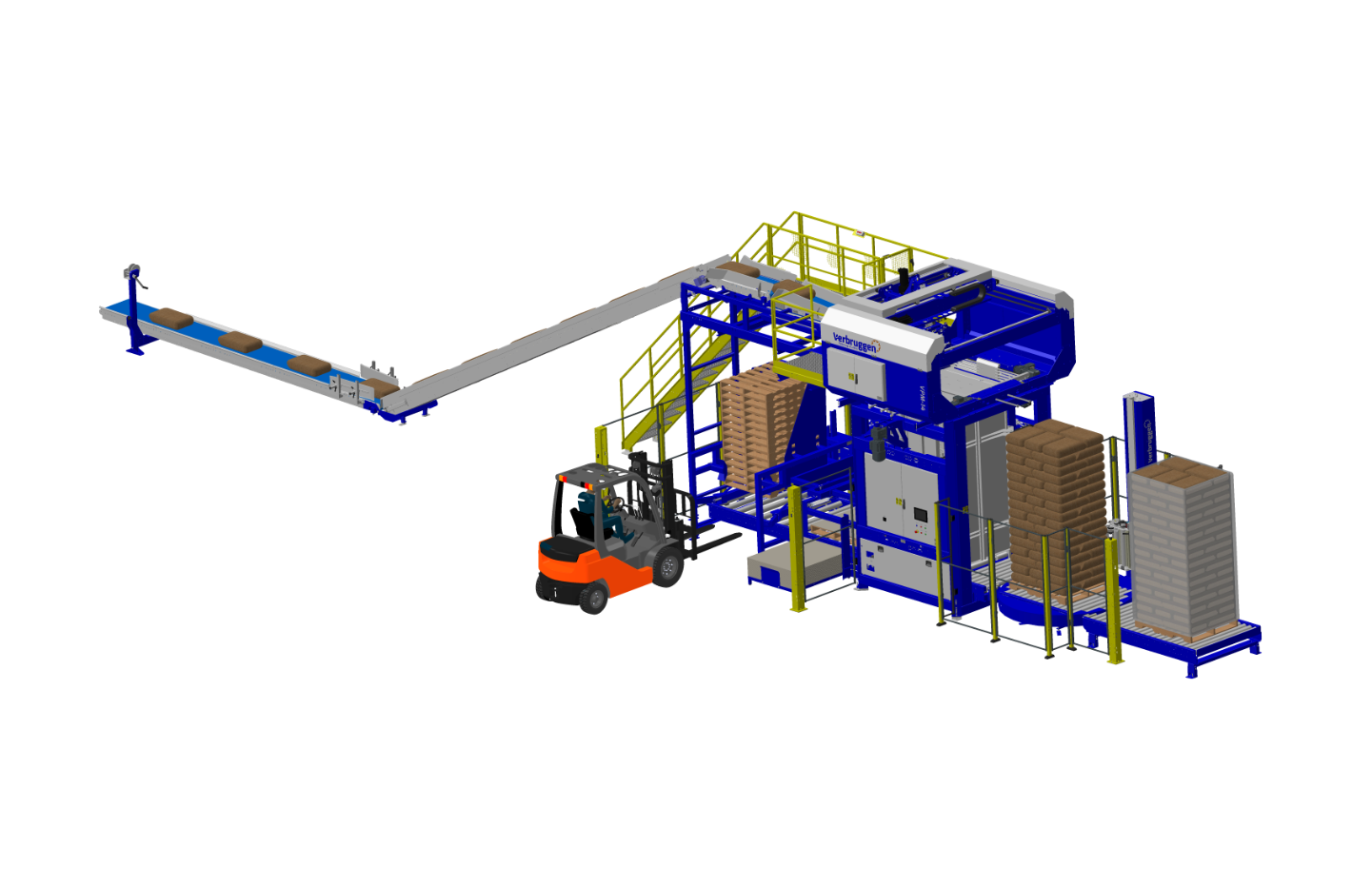

The VPM-5 has the bags supplied at floor level to the machine. The position of infeed is configurable at 10 different positions. Pallets are placed on the floor allowing full pallets to be easily changed by an empty one with a pallet jack, or forklift.

Our palletizing machines are also equipped with smart machine software and are easily operated by the user-friendly touchscreen. Remote access technology is also included, enabling remote service support from any location. The machine can also be built to suit your specific needs and is available with a wide range of options.

Most Selected Options:

- Pallet transport by roller conveyors with pallet dispenser and wrapper

- Center flaps (for bag width less than 470 mm)

- Standalone wrapper (separate from palletizer)

- External start new pallet

- Extra collar section for less changes between pallet dimensions

- Fork extension guides for easy moving the machine by forklift

Model Features

Touch screen with user-friendly interface

Easy configurable stacking patterns

Remote access

High infeed level

Low infeed level

Automatic stack / support transport

Vertical compression

4-sided stack enclosure

Entrance protection

Access platform

Specifications

Capacity (max. rate depending on configuration)

5 units per layer

550 units / hour

13 units per layer

550 units / hour

Max. layer dimensions (mm)

1600 x 1250

Package

Maximum weight (kg)

50

Minimum dimensions (mm)*1

350 x 220 x 50

Maximum dimensions (mm)

880 x 590 x 325

*1 = Based on 1 package per drop. Options for smaller package handling available on request.

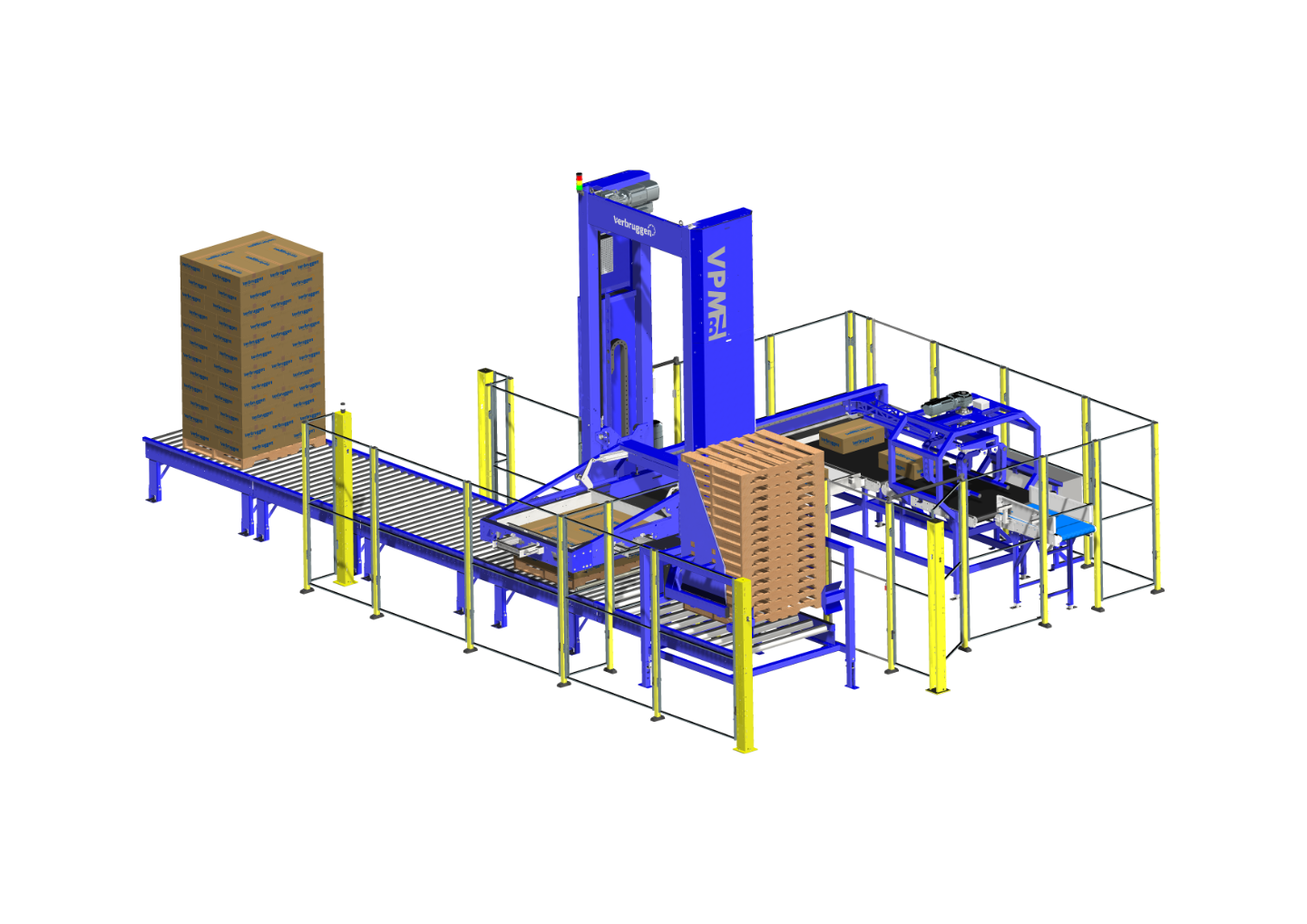

Most Sold Wrapping Machine

with the VPM-5

A Verbruggen wrapper, when used in conjunction with a palletizer, can greatly enhance the value of the palletizing process. The use of a Verbruggen wrapper with a palletizer can provide several benefits, including improved product protection, reduced labor costs, and increased efficiency. By securely wrapping the pallet, businesses can ensure that their products are protected from dust, moisture, and other environmental factors that can cause damage.

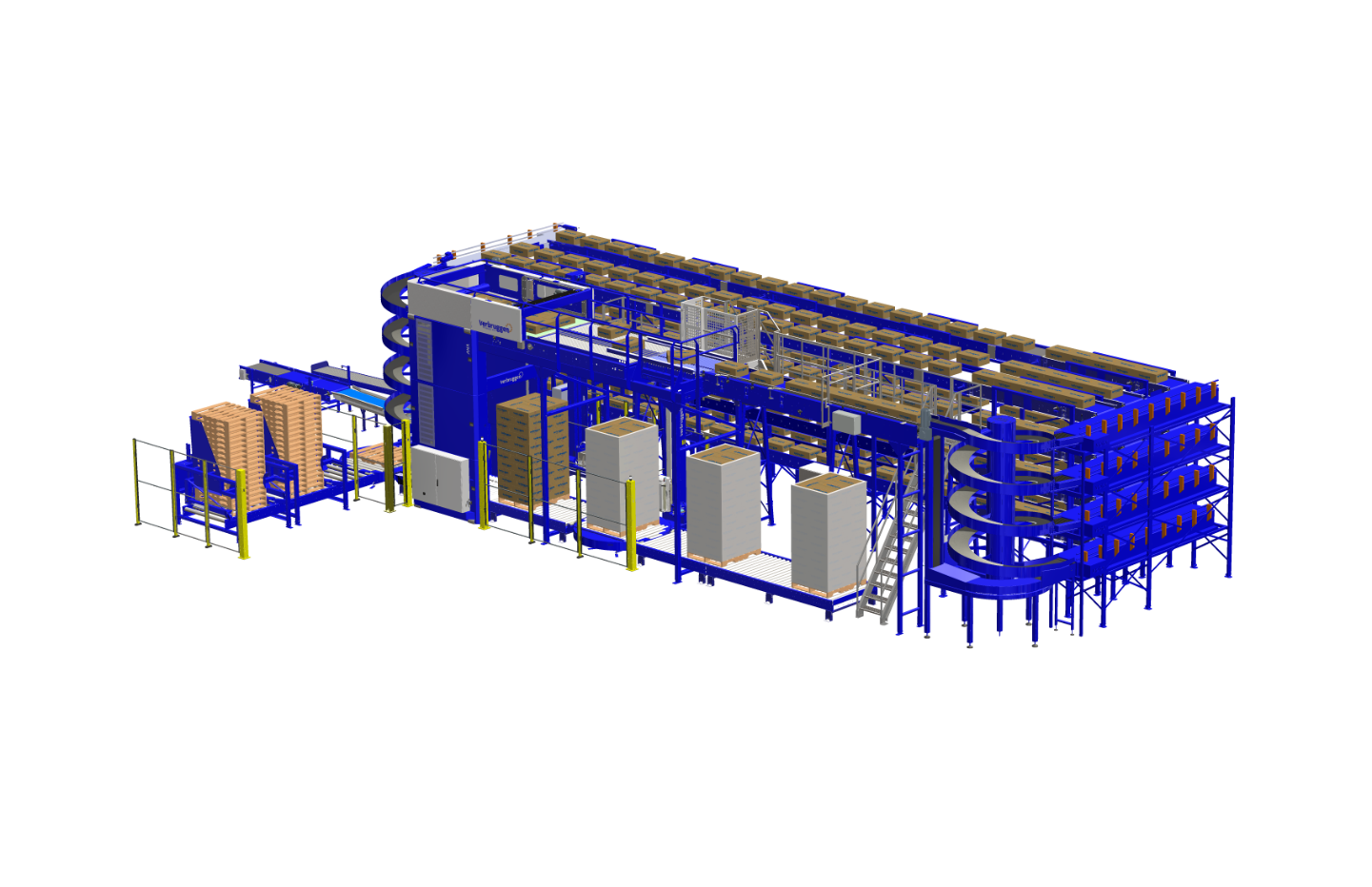

Discover Our Various Palletizers

VPM-5

Handling bags

VPM-7

Handling bags and / or boxes

VPM-8

Handling bags and / or boxes

VPM-10

Handling bags and / or boxes

VPM-14

Handling bags and / or boxes

VPM-BL

Handling boxes / cartons / crates / wraps

VPM-ACP

Handling boxes / cartons / crates / wraps

VPM-VHV

Handling boxes / cartons / crates / wraps

FREQUENTLY ASKED QUESTIONS

Palletizing refers to the process of arranging and stacking products on a pallet in a warehouse or manufacturing facility. The goal of palletizing is to create a stable and secure load that can be easily moved and stored using a forklift or pallet jack.

Palletizing can be done manually by workers or by using automated equipment, such as robots or conveyor systems. In a palletizing operation, the products to be palletized are typically brought to a central location, and then they are picked up and arranged on the pallet according to a specific pattern or configuration. The palletized products are then wrapped or secured in place using packaging materials such as shrink wrap or stretch wrap, and labeled with the necessary information for handling and storage.

Palletizing is a key part of many logistics and supply chain systems, as it allows for the efficient and safe handling and storage of products

A palletizing system is a type of or combination of automated equipment used in warehouses and manufacturing facilities to arrange and stack products on pallets. Palletizing systems can include a variety of different components, such as conveyor belts, robots, and packaging machinery, that work together to efficiently and accurately palletize products.

Palletizing systems can be programmed to handle a wide range of products and can work quickly and accurately, reducing the amount of manual labor required in a warehouse or manufacturing facility. They are often used in conjunction with other types of automation equipment, such as conveyor systems and packaging machinery, to improve efficiency and reduce costs

Verbruggen palletizing machines are designed for quality and durability, delivering an incredible stable stack and consistent performance. This exceptional focus on dependability makes Verbruggen the preferred choice of many industry leaders. Additionally, our machines are cutting edge as a result of extensive R&D, meaning that we can stack the most challenging products on the market.

- Latest technology in automation industry 4.0

- Customized solutions designed for your packaging and capacity requirements

- Industry-leading equipment solutions for optimal efficiency and durability

- First-class customer service and after-sales support.

- We can stack any type of products; bags, boxes, crates, cartons, even special product applications..

Verbruggen palletizing machines are designed for quality and durability, delivering an incredible stable stack and consistent performance. This exceptional focus on dependability makes Verbruggen the preferred choice of many industry leaders. Additionally, our machines are cutting edge as a result of extensive R&D, meaning that we can stack the most challenging products on the market.

- Latest technology in automation industry 4.0

- Customized solutions designed for your packaging and capacity requirements

- Industry-leading equipment solutions for optimal efficiency and durability

- First-class customer service and after-sales support.

- We can stack any type of products; bags, boxes, crates, cartons, even special product applications..

Verbruggen palletizing machines are designed for quality and durability, delivering an incredible stable stack and consistent performance. This exceptional focus on dependability makes Verbruggen the preferred choice of many industry leaders. Additionally, our machines are cutting edge as a result of extensive R&D, meaning that we can stack the most challenging products on the market.

- Latest technology in automation industry 4.0

- Customized solutions designed for your packaging and capacity requirements

- Industry-leading equipment solutions for optimal efficiency and durability

- First-class customer service and after-sales support.

- We can stack any type of products; bags, boxes, crates, cartons, even special product applications..

Verbruggen palletizing machines are designed for quality and durability, delivering an incredible stable stack and consistent performance. This exceptional focus on dependability makes Verbruggen the preferred choice of many industry leaders. Additionally, our machines are cutting edge as a result of extensive R&D, meaning that we can stack the most challenging products on the market.

- Latest technology in automation industry 4.0

- Customized solutions designed for your packaging and capacity requirements

- Industry-leading equipment solutions for optimal efficiency and durability

- First-class customer service and after-sales support.

- We can stack any type of products; bags, boxes, crates, cartons, even special product applications..

Verbruggen palletizing machines are designed for quality and durability, delivering an incredible stable stack and consistent performance. This exceptional focus on dependability makes Verbruggen the preferred choice of many industry leaders. Additionally, our machines are cutting edge as a result of extensive R&D, meaning that we can stack the most challenging products on the market.

- Latest technology in automation industry 4.0

- Customized solutions designed for your packaging and capacity requirements

- Industry-leading equipment solutions for optimal efficiency and durability

- First-class customer service and after-sales support.

- We can stack any type of products; bags, boxes, crates, cartons, even special product applications..

Palletizing operation is the process of arranging and stacking products on a pallet in a warehouse or manufacturing facility.

What is the goal of the palletizing operation?

The goal of palletizing is to create a stable and secure load that can be easily moved and stored using a forklift or pallet jack.

Palletizing operations can be done manually by workers or by using automated equipment, such as robots or conveyor systems. In a palletizing operation, the products to be palletized are typically brought to a central location, and then they are picked up and arranged on the pallet according to a specific pattern or configuration. The palletized products are then wrapped or secured in place using packaging materials such as shrink wrap or stretch wrap, and labeled with the necessary information for handling and storage.

Palletizing operations are a key part of many logistics and supply chain systems, as they allow for the efficient and safe handling and storage of products

Inline palletizing is a method of arranging products on a pallet where the products move along a production line. This can be done either manually or by a palletizer. The benefits of Inline palletizing depends on the specific needs of the production or warehouse.

What is an inline palletizing machine?

An inline palletizing machine automatically stacks products on pallets as they move through the inline palletizing system along a conveyor or production line. The inline palletizing system uses special equipment, such as robotic arms or automated palletizers, to accurately place products on the pallets according to predetermined patterns or configurations.

When to use inline palletizing?

Inline palletizing machine is often used when products are produced at a high rate and need to be quickly and efficiently palletized for shipping or storage. It can also be used to improve the accuracy and consistency of the palletizing process because palletizers, robots or automated systems can be programmed to place products on the pallet in a specific pattern or configuration. Inline palletizing can be more efficient and cost-effective than traditional manual palletizing methods, especially for large volumes.

Palletizing products is the process of arranging and stacking products on a pallet, done in a manufacturing or warehouse facility. The goal of palletizing products is to create a stable and secure load that can be easily moved and stored using a forklift. Palletizing products can be done manually or by using machinery, such as palletizers, palletizing robots or conveyor systems.

In a palletizing operation, the products to be palletized are typically brought to a central location, and then they are picked up and arranged on the pallet according to a specific pattern or configuration. The palletized products are then wrapped or secured in place using packaging materials such as shrink wrap or stretch wrap, and labeled with the necessary information for handling and storage.

A palletizing robot -or palletizer robot- is a type of industrial robot (robotic machine) that is used to stack and unstack items on pallets in a warehouse or manufacturing environment. These robots are typically equipped with a gripper or suction cup to pick up items, and are programmed to arrange them in a specific pattern or configuration on a pallet.

Palletizing robots and palletizer machines can be the same thing. A typical difference can be the use of a robotic arm versus the use of a manipulator. In the vast majority of cases, a palletizer with a manipulator achieves a higher stacking speed than a robotic arm.

Palletizing robots can work quickly and accurately, and can be used to handle a wide range of products, including boxes, bags, and other types of packages. They are often used in conjunction with other automation equipment, such as conveyor systems and packaging machinery, to improve efficiency and reduce the amount of manual labor required in a warehouse or manufacturing facility