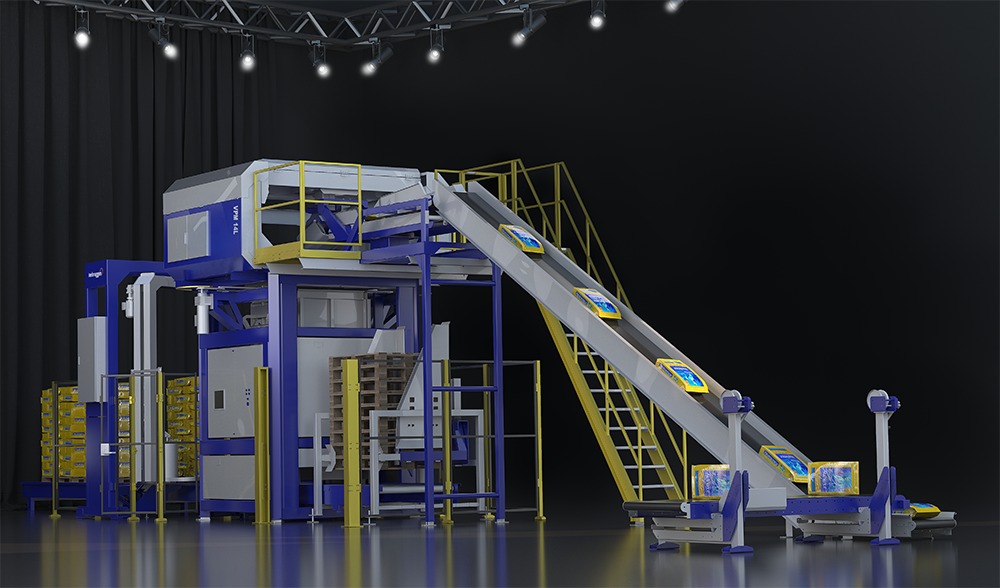

Bag Palletizer

Are you in need of quick, efficient & perfectly stacked bags on pallets or sheets? And also reduce labor costs & downtime, while optimizing loading space? In that case you found your match with Verbruggen bag palletizing machines. These bag palletizers provide a significant increase in productivity, improve operations, reduce labor costs & downtime, and create a safer and more efficient workplace.

The Bag Palletizers & Palletizing Machines By Verbruggen

Overview Bag Palletizing Machines

Discover Our Various Palletizers

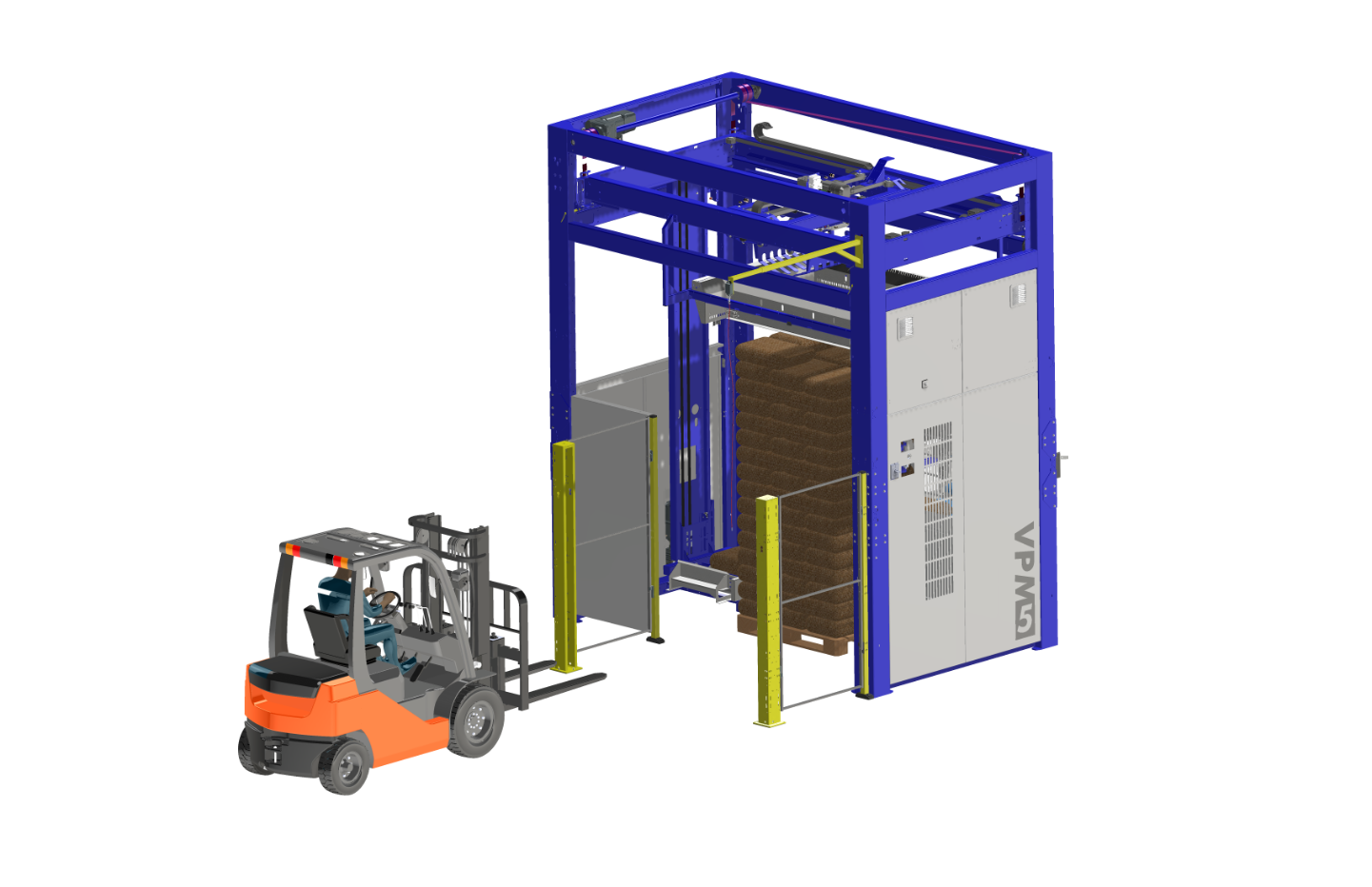

VPM-5

Handling up to

550 bags per hour

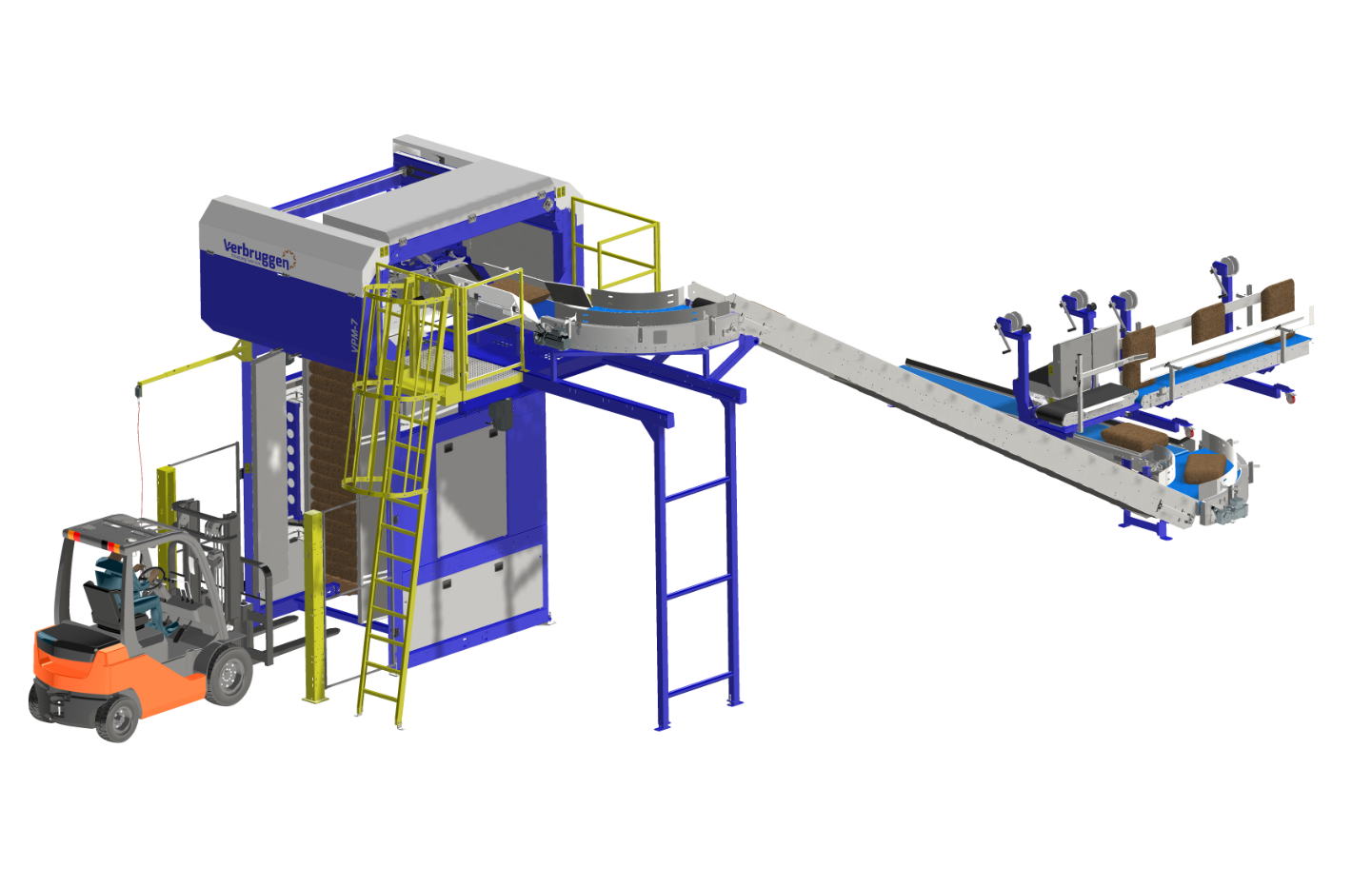

VPM-7

Handling up to

1025 bags per hour

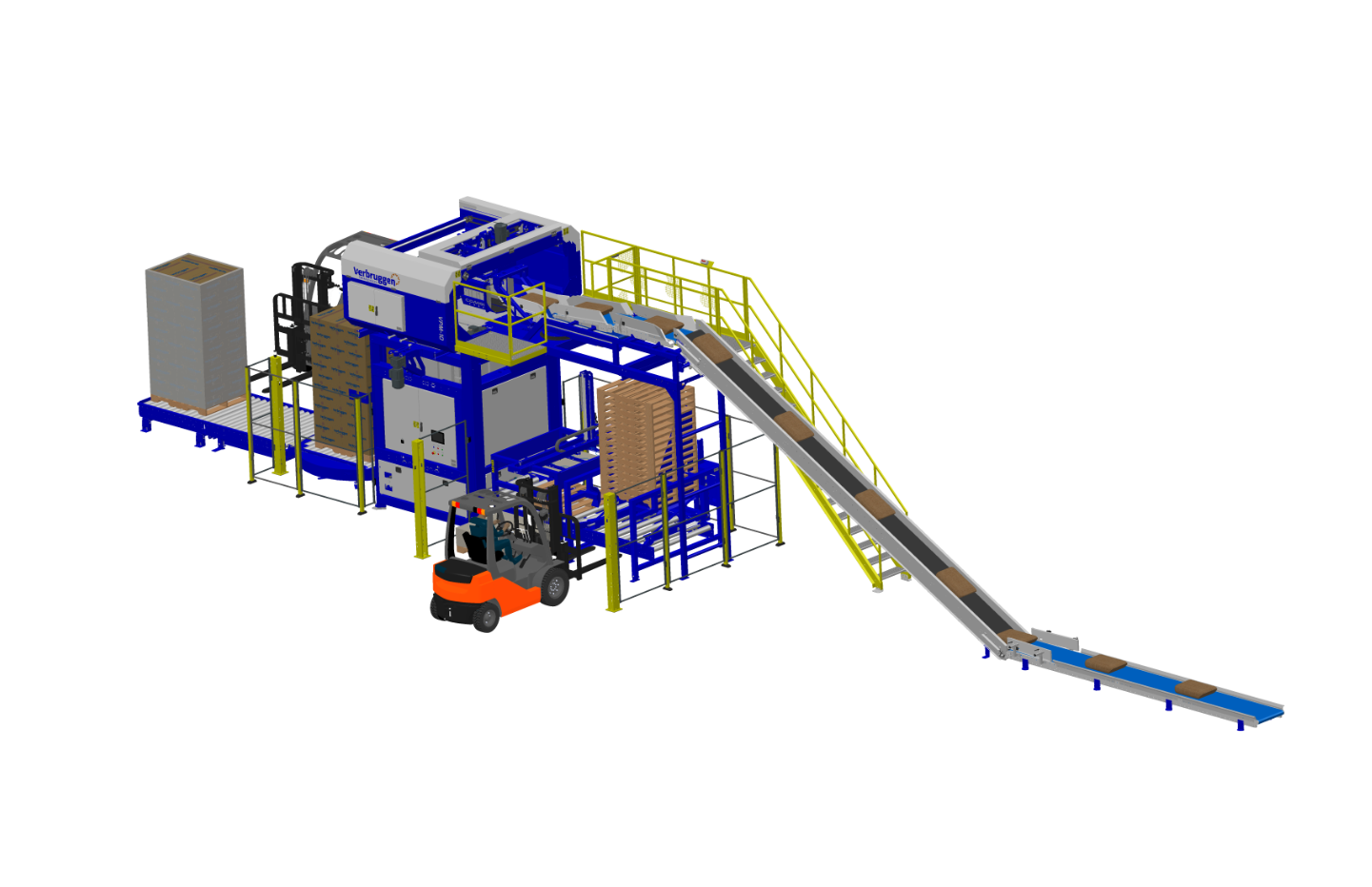

VPM-8

Handling up to

1025 bags per hour

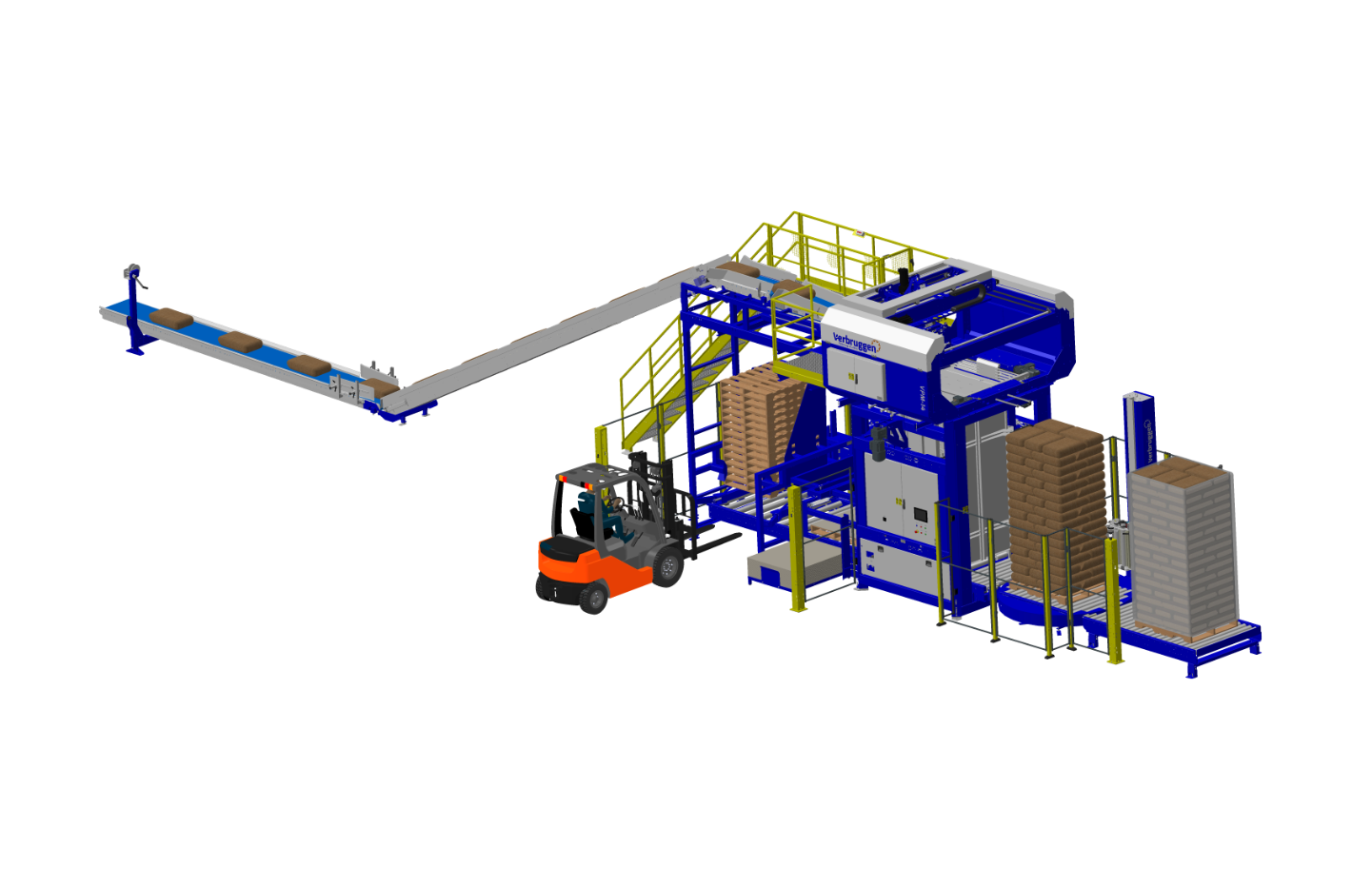

VPM-10

Handling up to

1710 bags per hour

VPM-14

Handling up to

2280 bags per hour

Bag Palletizing

A bag palletizer machine or bag stacking machine is specifically designed for bag palletizing, which is a crucial process in various industrial and manufacturing environments. It involves the organized and efficient stacking of bags onto pallets, simplifying packaging and logistic processes and ensuring secure and structured storage or shipping.

Bag palletizer machines are designed to handle various types, materials and dimensions of bags. They play an essential role in optimizing production processes and contribute to productivity and safety across various market segments including logistics, and feed & food processing.

The Advantages Of A Bag Palletizer Machine

A bag stacking machine offers a range of benefits for businesses looking to streamline their bag palletizing processes. A bag stacking machine, such as the innovative systems offered by Verbruggen, brings a wide array of benefits to businesses across various industries, including:

1. Improved Efficiency

Bag stacking machines provide a consistent and efficient method for stacking bags. This results in increased productivity by reducing the reliance on manual labor and minimizing errors.

2. Cost Savings

Automation of bag stacking can lead to significant cost savings in labor. Additionally, the reduction in errors and product damages during stacking helps lowering expenses related to production losses and product returns.

3. Consistent Quality

Bag stacking machines ensure uniform, stable, and precise stacking, which enhances the quality of pallets. This is vital for businesses aiming to meet strict quality standards and customer expectations.

4. Versatility

These machines are adaptable to various bag types and product specifications. Whether you handle food, petfood, fresh produce, or other items, bag stacking machines can be tailored to your specific needs.

5. Time Efficiency

Bag stacking machines work efficiently, saving valuable time compared to manual palletizing methods. This speed is especially advantageous for industries with high production volumes.

By integrating a bag stacking machine from Verbruggen into your operations, you can capitalize on these benefits. By integrating a Verbruggen bag stacking machine into your operations, you can leverage these advantages and elevate your operational efficiency.

Palletizing Bags In Different Industries

Bag palletizers, versatile machines designed to efficiently stack bags, play a crucial role in multiple industries. These industries include food industry, feed industry, fresh produce, seed industry, garden products, construction materials, as well as retail and warehousing. Bag palletizers contribute to increased efficiency, cost savings, and improved product quality in each of these sectors.

Different Bag Dimensions With Bag Palletizing Machines

Bag palletizers are designed to handle a wide range of bag types, materials and dimensions. Whether it’s small bags containing fine powders or large bags filled with bulk products, bag palletizers are versatile machines that adapt to the specific needs of various industries. This adaptability allows them to efficiently and accurately stack bags of various dimensions.

The flexibility of bag palletizers makes them ideal for businesses working with bags of different dimensions. Whether you’re dealing with bags weighing a few kilograms or bags up to 70 kilograms, bag palletizers can streamline the stacking process, increasing productivity and improving efficiency.

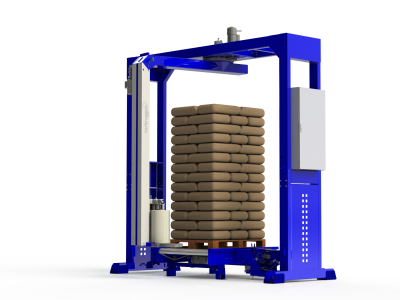

Bag Wrapping Machines

Suitable for bag palletizers

A Verbruggen bag wrapper, when used in conjunction with a palletizer, can greatly enhance the value of the palletizing process. The use of a Verbruggen wrapper with a palletizer can provide several benefits, including improved product protection, reduced labor costs, and increased efficiency. By securely wrapping the pallet, businesses can ensure that their products are protected from dust, moisture, and other environmental factors that can cause damage.

Are you interested in learning more about the possibilities offered by wrapping machine solutions? Discover our different bag wrapping machines or get in touch for more information. See all contact options at our contact page.

VTW Wrapping Machine

The VTW wrapping machine uses a turntable design, and it will usually be integrated within a palletizing line.

VAW Wrapping Machine

The VAW wrapping machine wraps pallets with a very high capacity using a robust swing arm.

VSW Wrapping Machine

The VSW wrapping machine is equipped with a turntable, and it will be used separately from the palletizer.

FREQUENTLY ASKED QUESTIONS

The distinction between bag and box palletizers is rooted in the types of loads they are capable of handling and the particular purposes they are intended for, as their names imply. A bag palletizer is explicitly created for the stacking of bags containing bulk goods of diverse dimensions on a pallet, whereas box palletizers are customized for the arrangement of boxes, cartons, crates, and wraps on a pallet. In essence, the contrast between bag and box palletizers primarily centers on the specific load they can accommodate.

A bag-in-box palletizer is a specialized system tailored for handling bag-in-box packaging, typically cardboard boxes with flexible bags holding liquids, semi-liquids, or solids like wine, juice, sauces, or wet petfood. This packaging is highly efficient and popular in the food, petfood, and beverage industries.

The bag-in-box palletizer automates the handling of these packages, picking them up, securely placing them on pallets, and stacking them to the desired height, optimizing packaging efficiency and ensuring secure transportation.

This system provides significant advantages, particularly for companies using bag-in-box packaging in their production and distribution processes.

Robotic Bag Palletizer

A robotic bag palletizer and a Verbruggen palletizer are two different systems used for stacking bags on pallets within various applications. Each of these systems has its own specific features and advantages.

Robotic Bag Palletizing System

A robotic bag palletizer is a system that utilizes robots or robot-like devices to place bags containing various products on a pallet. These robots are equipped with grippers or suction cups that enable them to pick up the bags and place them securely on the pallet.

On the other hand, Verbruggen palletizers are machines designed specifically for the automated stacking of bags on pallets. These machines can achieve significant production capacities and are known for their reliability, stability, and user-friendliness.

The difference between box, bag, tray, and crate palletizers lies in their specific applications and the type of load they can handle.

Box Palletizer:

A box palletizer is designed to stack boxes, crates, or similar packagings on a pallet, making them ideal for industries with standardized products in boxes.

Bag Palletizer:

A bag palletizer is specifically designed for stacking bags of bulk goods such as flour, cement, animal feed, and chemicals. They are known for their reliability, stability, and user-friendliness.

Crate & Tray Palletizer:

A crate palletizer is designed to stack crates or trays on a pallet, which is particularly important in logistics and the transportation of goods in sturdy crates.

The choice between these palletizers depends on the nature of the products to be stacked and the specific requirements of the industry. Each type of palletizer has its own advantages and applications.