Our Pallet Wrapping Machines

A pallet wrapping machine, also known as a (stretch) wrapper, is a machine used to wrap stretch film around a pallet. This is done to secure the load on the pallet and protect it during transport or storage. They are commonly used in industries such as manufacturing, logistics, and warehousing to streamline packaging and shipping processes and improve overall efficiency.

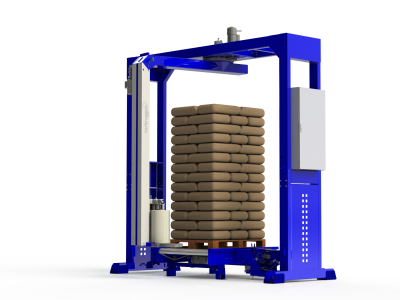

Verbruggen Automatic Wrapping Machines

VAW Wrapping Machine

Verbruggen Arm Wrapping Machine

The VAW wrapping machine wraps pallets with a very high capacity using a robust swing arm.

CAPACITY

40 to 60 pallets / hour

WRAPPING HEIGHT

Max. 2500 mm

PALLET DIMENSIONS

Max. 1200 x 1200 mm

PALLET WEIGHT

Max. 1500 kg

TRANSPORT

Roller or chain conveyor

TIE-OFF

Clipper, Heat Seal or manually

WRAPPING MATERIAL

Film, mesh, mesh and paper

BRAKING SYSTEM

Electro motor

OPTIONS

A4-tag dispenser

VTW Wrapping Machine

Verbruggen Table Wrapping Machine

The VTW wrapping machine uses a turntable design, and it will usually be integrated within a palletizing line.

CAPACITY

30 to 40 pallets / hour

WRAPPING HEIGHT

Max. 2500 mm

PALLET DIMENSIONS

Max. 1200 x 1200 mm

PALLET WEIGHT

Max. 1500 kg

TRANSPORT

Roller or chain conveyor

TIE-OFF

Clipper, Heat Seal or manually

WRAPPING MATERIAL

Film, mesh, mesh and paper

BRAKING SYSTEM

Electro motor

OPTIONS

Top sheet, top press plate

VSW Wrapping Machine

Verbruggen Stand-alone Wrapping Machine

The VSW wrapping machine is equipped with a turntable, and it will be used separately from the palletizer.

CAPACITY

20 to 30 pallets / hour

WRAPPING HEIGHT

Max. 2500 mm

PALLET DIMENSIONS

Max. 1200 x 1200 mm

PALLET WEIGHT

Max. 1500 kg

TRANSPORT

No

TIE-OFF

Manually

WRAPPING MATERIAL

Film, mesh

BRAKING SYSTEM

Mechanical brake

OPTIONS

Remote control, ramp

Semi- or Fully Automatic Wrapping Machine?

Using a semi-automatic wrapping machine you tie-off the pallets manually, if desired the wrapping machine can be operated with a remote control.

Using a fully automatic wrapping solution from Verbruggen the wrapping material is tied automatically by either staples (Clipper) or heat (Heat Seal). The fully automatic solution is capable of wrapping approx. 10 or more pallets / hour.

Differences between semi-automatic and fully automatic wrapping machines

While both semi-automatic and fully automatic wrapping machines offer benefits for businesses looking to increase productivity and improve the quality of their wrapped products, there are some significant differences between the two. A fully automatic wrapping machine is a more advanced and sophisticated option, offering a higher level of automation and features that can significantly improve the efficiency and effectiveness of the wrapping process.

Benefits of a fully automatic wrapping machine

One of the primary benefits of a fully automatic wrapping machine is its ability to operate continuously with minimal human intervention. Once the machine is programmed and set up, it can run for extended periods without the need for frequent manual adjustments or monitoring. This can help businesses achieve higher production volumes and faster throughput rates, improving overall productivity and profitability.

Speed of a fully automatic wrapping machine

In addition to the other advantages of fully automatic wrapping machines, another significant benefit is their higher speed compared to semi-automatic wrapping machines. With advanced automation and programmable settings, fully automatic machines can wrap pallets at much higher speeds than semi-automatic wrapping machines. This can help businesses achieve faster throughput rates and higher production volumes. Using a fully automatic wrapping solution from Verbruggen the wrapping material is tied automatically by either staples (Clipper) or heat (Heat Seal). The fully automatic solution is profitable with approx. 10 or more pallets / hour.

Automatic wrapping machines are an excellent investment for businesses looking to streamline their wrapping processes, increase efficiency, and improve product quality. With its advanced features and capabilities, this type of machine can offer significant benefits for businesses in a variety of industries, including food, consumer goods, and manufacturing.

Why Choose a Wrapping Machine?

To make your palletized products ready for transport, you can make use of our semi- / fully automatic wrapping machines. To prevent your products from possible external damages and to make your products stable and fixed to the pallet during transportation, we provide you with a variety of equipment for wrapping materials depending on your product features, for example:

- Film: Prevent products from environmental influences such as humidity and dust.

- Mesh: Allow fresh fruit and vegetables to breath during transportation.

- Combination of mesh and paper: Prevent products’ exposure from UV light.

With more than 30 years of technology innovation experiences, Verbruggen has developed a complete range of wrapping machines, which can be categorized into three main series.

VAW – Verbruggen Arm Wrapping Machine

An arm wrapping machine is a type of wrapping machine that uses a rotating arm to wrap pallets. The arm moves around the product on a pallet conveyor, applying the wrapping material and securing it in place. One of the main advantages of an arm wrapping machine is its ability to wrap large or irregularly shaped pallets efficiently and effectively. With programmable settings and sensors, arm wrapping machine can adjust the wrapping parameters based on the dimensions and shape of the pallet, ensuring a secure and consistent wrap every time. Additionally, arm wrapping machines offer speed and flexibility, allowing businesses to wrap pallets quickly and efficiently while maintaining a high level of pallet quality.

VTW – Verbruggen Table Wrapping Machine

A table wrapping machine is a type of wrapping machine that uses a turntable to wrap pallets. The pallet is placed on the turntable, and the wrapping material is dispensed automatically, wrapping the pallet securely. One of the main advantages of a table wrapping machine is its simplicity and ease of use. With minimal training required, operators can quickly and easily wrap pallets of varying dimensions and shapes, improving efficiency and productivity.

VSW – Verbruggen Stand-alone Wrapping Machine

A stand-alone wrapping machine is a type of wrapping machine that operates independently of other packaging equipment. Unlike integrated systems, stand-alone wrapping machines can be used as a stand-alone unit, allowing businesses to wrap pallets without the need for additional equipment or complex installation. One of the main advantages of a stand-alone wrapping machine is its flexibility and portability. They can be easily moved to different locations or used with existing production lines, allowing businesses to customize their packaging processes to suit their unique needs.

Additionally, stand-alone wrapping machines offer speed and efficiency, reducing the need for manual labor and increasing productivity. With their compact footprint and advanced automation, stand-alone wrapping machines can help businesses save time and money while maintaining a high level of product quality.

Frequently asked questions about Pallet Wrapping Machines

What is a Pallet Wrapping Machine?

A pallet wrapping machine is a piece of equipment that automates the process of wrapping pallets with various types of wrapping material. These machines come in various footprints and styles, depending on the needs of the business. They are used to protect palletized products during transportation, storage, and handling.

The wrapping machines work by holding the pallet in place and automatically applying the wrapping material. They can be programmed to adjust the wrapping parameters based on the dimensions and shape of the pallet, ensuring a secure and professional-looking pallet.

Why a Verbruggen Pallet Wrapping Machine?

For over 30 years we supply the best wrapping machines to ambitious companies. The Verbruggen pallet wrapping machine assures a high uptime and local support.

These machines are designed with advanced technology and high-quality materials, ensuring long-lasting performance and low maintenance costs. They offer a range of features and options, such as automatic film cutters, adjustable tension controls, and touch screen interfaces, to provide a tailored packaging solution for businesses of all sizes. Verbruggen Pallet Wrapping Machines are a trusted choice for optimizing packaging and shipping processes, and can help businesses save time and money while improving overall productivity.

How to use a pallet wrapper for shipping?

Wrapping pallets for shipping is an important step in ensuring that your products arrive at their destination safely and securely. To wrap a pallet for shipping, the pallet must first be loaded onto the wrapper and the film loaded onto the machine. The wrapping parameters must be adjusted based on the size and shape of the pallet and the type of product being shipped.

Once the wrapper is activated, the film will be applied automatically, covering all sides and corners of the pallet to provide stability and protection during transportation. Finally, the wrapped pallet should be inspected for any loose areas or imperfections before being labeled and moved to its destination.

With the use of a pallet wrapper, this process can be completed quickly and efficiently, reducing the risk of damage to your products and ensuring a successful shipment.

What is a stretch wrapping machine?

Stretch wrapping machines are a versatile and efficient way to wrap products or pallets for storage or shipping. These machines use stretch film, a flexible plastic material, to securely wrap products of various sizes and shapes. The film is stretched around the product, providing protection and stability during transport or storage.

For over 30 years we supply the best wrapping machines to ambitious companies. The Verbruggen pallet wrapping machine assures a high uptime and local support.

How to wrap firewood on to pallets

Using a pallet wrapper to wrap firewood onto pallets is a quick and easy process that saves time and effort. Once the firewood is stacked, the wrapper is activated to apply the stretch film automatically, ensuring full coverage and protection during shipping or storage. An automated pallet wrapper saves time and effort when wrapping firewood onto pallets. It ensures consistent and secure wrapping, reducing the risk of damage or product loss.