Palletizing Solutions for Agriculture Industry

In the agricultural industry, where the cultivation of plants and livestock is both a science and an art, efficient product handling is crucial. At Verbruggen, we specialize in palletizing solutions specifically designed for agricultural products such as potatoes, onions, carrots, and beets. Our palletizers are capable of handling a wide range of packaging formats. With our expertise and innovative technology, we ensure smooth and precise stacking of your agricultural products, optimizing your operations and maximizing efficiency.

Agricultural Industry and Stacking Products

Agriculture is the science and art of cultivating plants and livestock. For applications of stacking products on pallets (palletizing) in the agricultural industry, we mean primarily the products potatoes, onions, carrots and beets. Verbruggen palletizers can handle bags from 2,5 kg (5 lbs) up to bags of 75 kilos (165 lbs), boxes in different size and bags in boxes.

Verbruggen’s History in Stacking Agriculture Products

Verbruggen originally started in the agriculture. The first Verbruggen palletizer was sold to a potato farmer, back in 1991. From this starting point, agricultural industry became the first and largest market of Verbruggen. Over the years an enormous number of machines was installed all over the world, bringing ultimate solutions for stacking potatoes, onions and carrots in bags, crates and boxes.

Over the years, thanks to our innovative drive and solution-oriented engineering, the machines improved constantly, resulting in a current superior functionality, reliable equipment and great product results by our world-famous palletizing machines. Verbruggen receives a progressive and trusted reputation among growers worldwide.

Stacking Boxes in Agriculture

In addition to stacking boxes, palletizing solutions such as palletizing machines are commonly used in the agriculture industry for large-scale storage and transport of crops. Palletizing involves the use of automated machinery to stack boxes or other containers onto pallets, creating a stable unit load that can be easily transported using forklifts or other equipment.

Palletizing solutions offer several advantages, including increased speed and efficiency in handling, reduced labor costs, and improved safety for workers by minimizing manual lifting and handling.

Palletizing machines can be customized to handle different box sizes and weights, and can be integrated with warehouse management systems for seamless logistics operations. Overall, palletizing solutions are a valuable tool for the agriculture industry, providing a cost-effective and efficient way to store and transport crops.

Stacking Bags in Agriculture

Stacking bags is a vital practice in the agriculture industry, especially for storing and transporting crops like onions, potatoes, and vegetables. Stacking bags provides benefits such as increased storage space, reduced labor costs, and minimized crop damage. Automated palletizing machines can be customized to handle different bag sizes and weights, further enhancing the efficiency of the process. Check out all the possibilities of a custom-made palletiser machine.

Stacking Crates in Agriculture

The agriculture industry relies heavily on product stacking in crates to efficiently store and transport vegetables from the farm to the processing facility and ultimately to the end consumer. By using crates and palletizing machines, the industry can reduce waste, improve efficiency, and contribute to its success and sustainability.

Sorting and grading the vegetables according to size and weight ensures that the crates are filled to capacity without overloading them or damaging the produce. Pallet machines can be used to stack the crates onto the pallets, creating a stable load that is easy to transport and store.

Agricultural Products for Palletizing Applications

Onions

Potatoes

Carrots

Beetroots

Various advantages of palletizing (solutions) in the agriculture industry

Palletizing solutions have become increasingly popular in the agriculture industry, especially with the use of palletizing machines. These machines have revolutionized the way products are stacked and transported, offering greater efficiency and cost savings for farmers and growers.

Specific stacking needs for agriculture

In the agriculture industry, palletizing machines are commonly used to stack crates filled with fruits and vegetables onto pallets. These machines have the ability to stack crates in a precise and efficient manner, ensuring that the maximum number of crates can be loaded onto a single pallet.

Handling capacity Verbruggen palletizers for agricultural industry

For applications of stacking products on pallets (palletizing) in the agricultural industry, we mean primarily the products potatoes, onions, carrots and beets. Verbruggen palletizers can handle bags from 2,5 kg (5 lbs) up to bags of 75 kilos (165 lbs), boxes in different sizes and bags in boxes.

Palletizing machines improve safety & productivity in agriculture

Palletizing machines can also improve safety in the workplace by minimizing the need for manual lifting and handling. This helps to prevent workplace injuries and increases productivity by allowing workers to focus on other tasks.

Palletizing Solutions for Agricultural Applications

Verbruggen has extensive experience in stacking various agricultural product types such as potatoes, onions, carrots and beets. Our team of engineers are continually innovating and developing our machines and software, allowing us to offer the most technically advanced & effective palletizing solutions possible.

Verbruggen’s Palletizing USP’s

Based on our extensive experience in palletizing, Verbruggen palletizers offer the following advantages in stacking your bags, boxes or crates with agricultural products:

Videos of Palletizing Solutions in Agriculture

Discover Our Various Palletizers

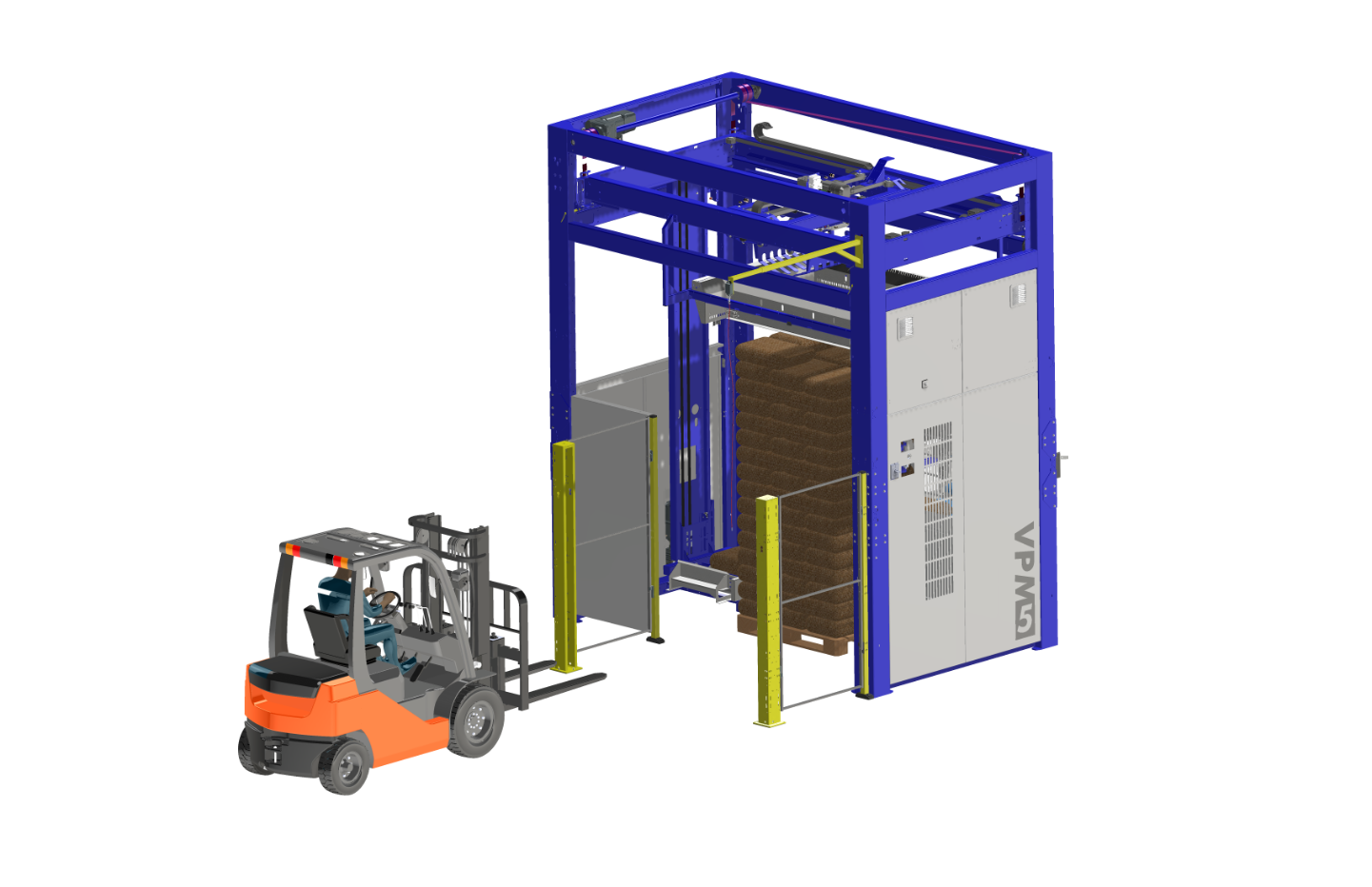

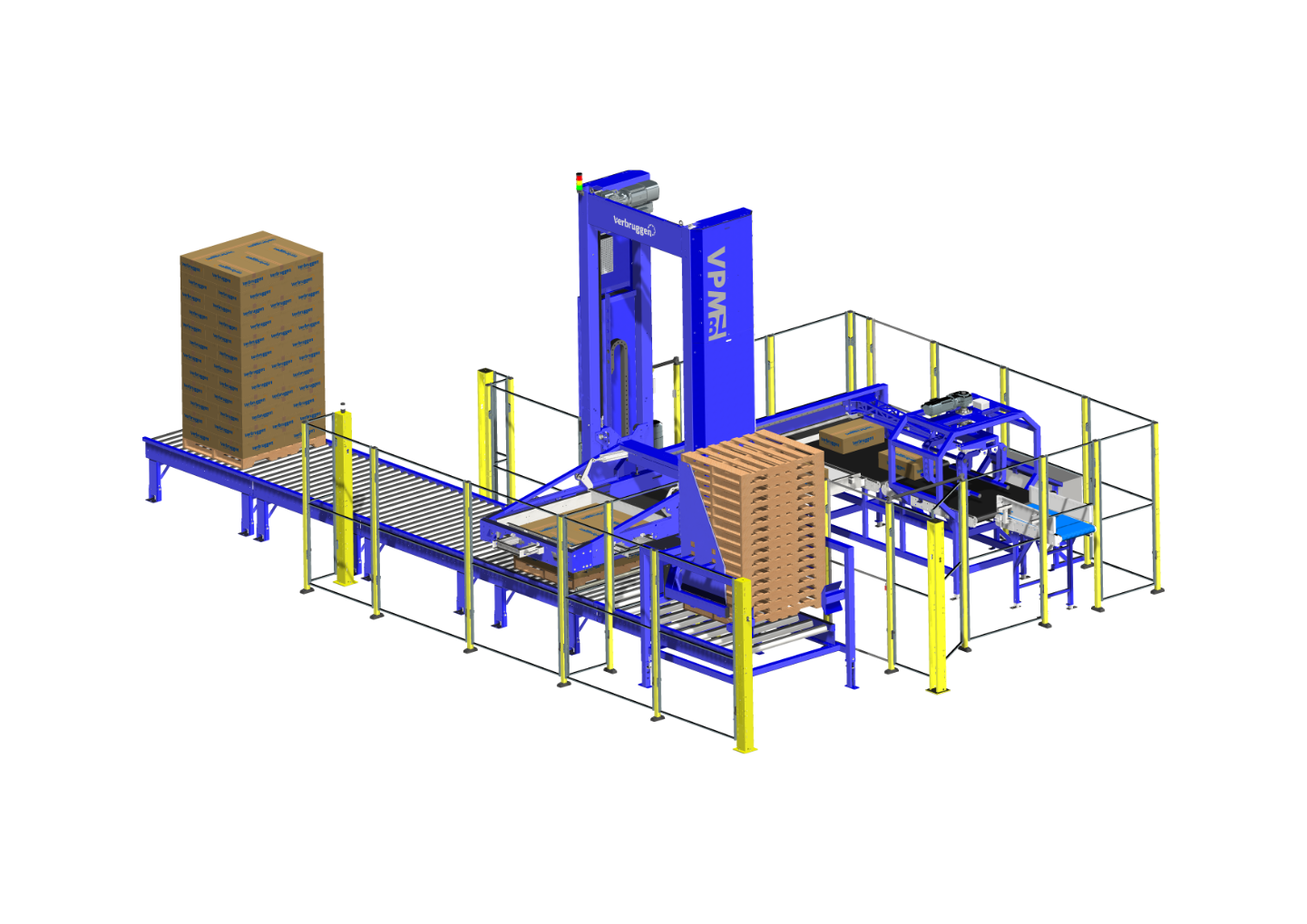

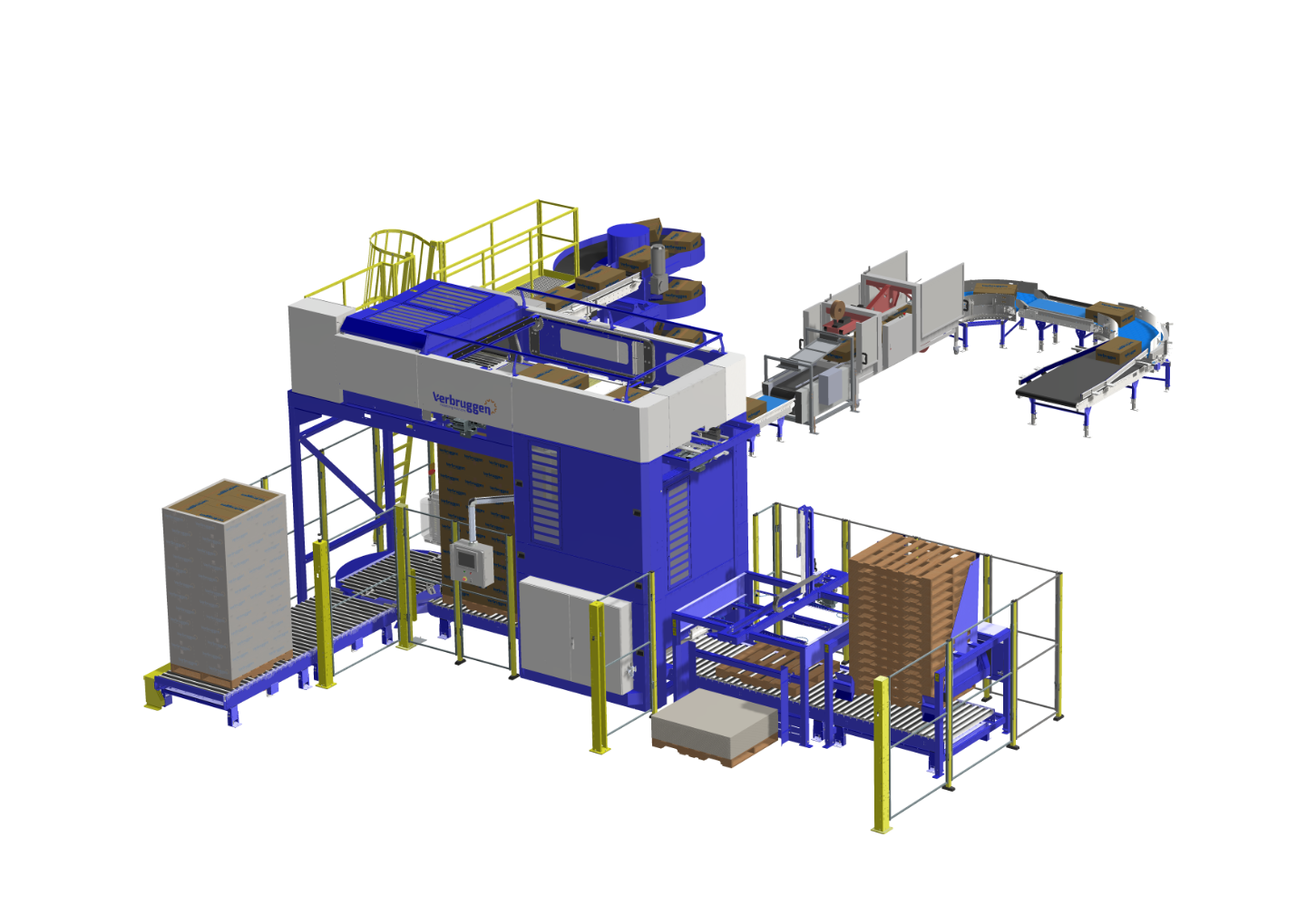

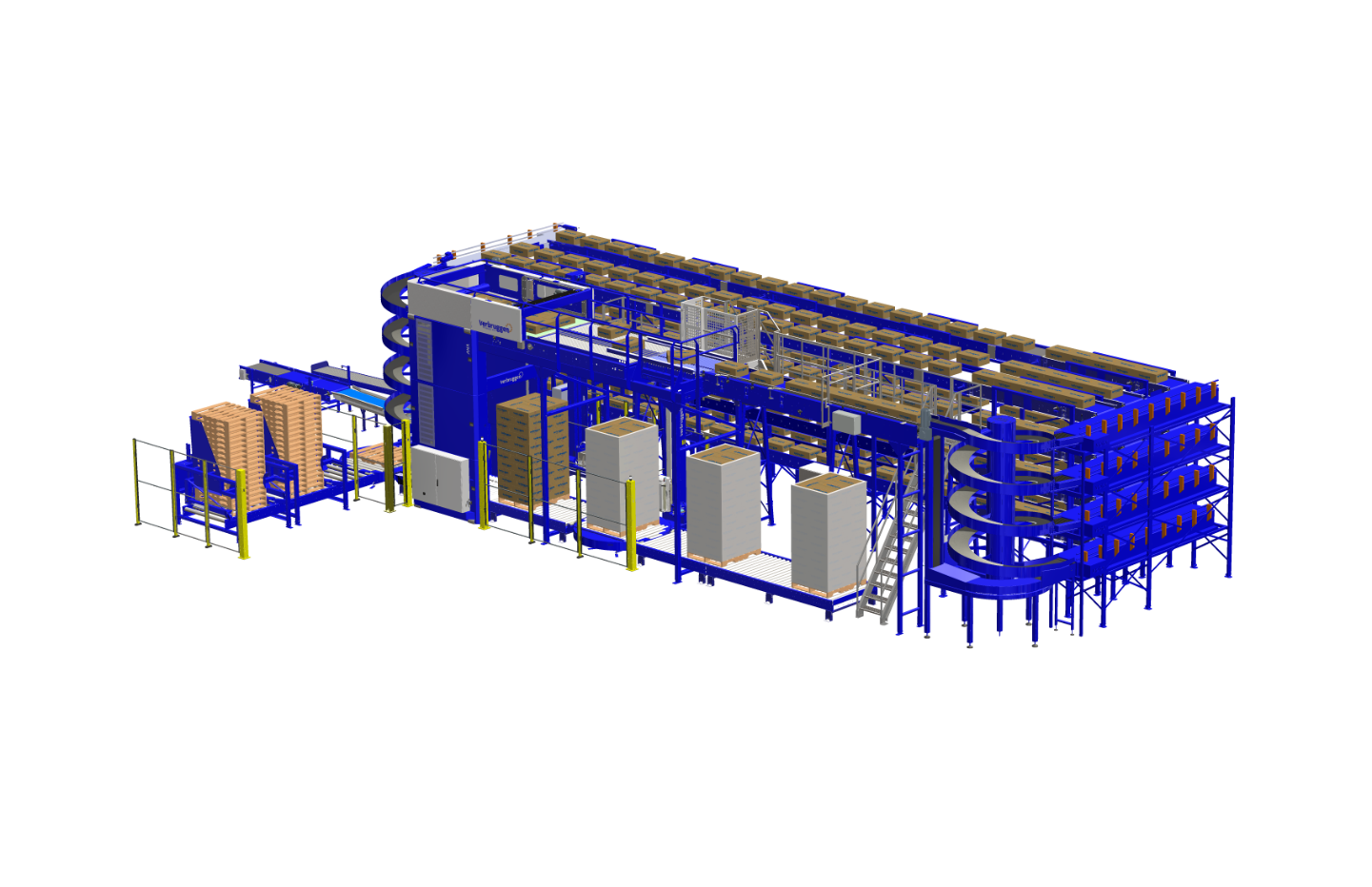

VPM-5

Handling bags

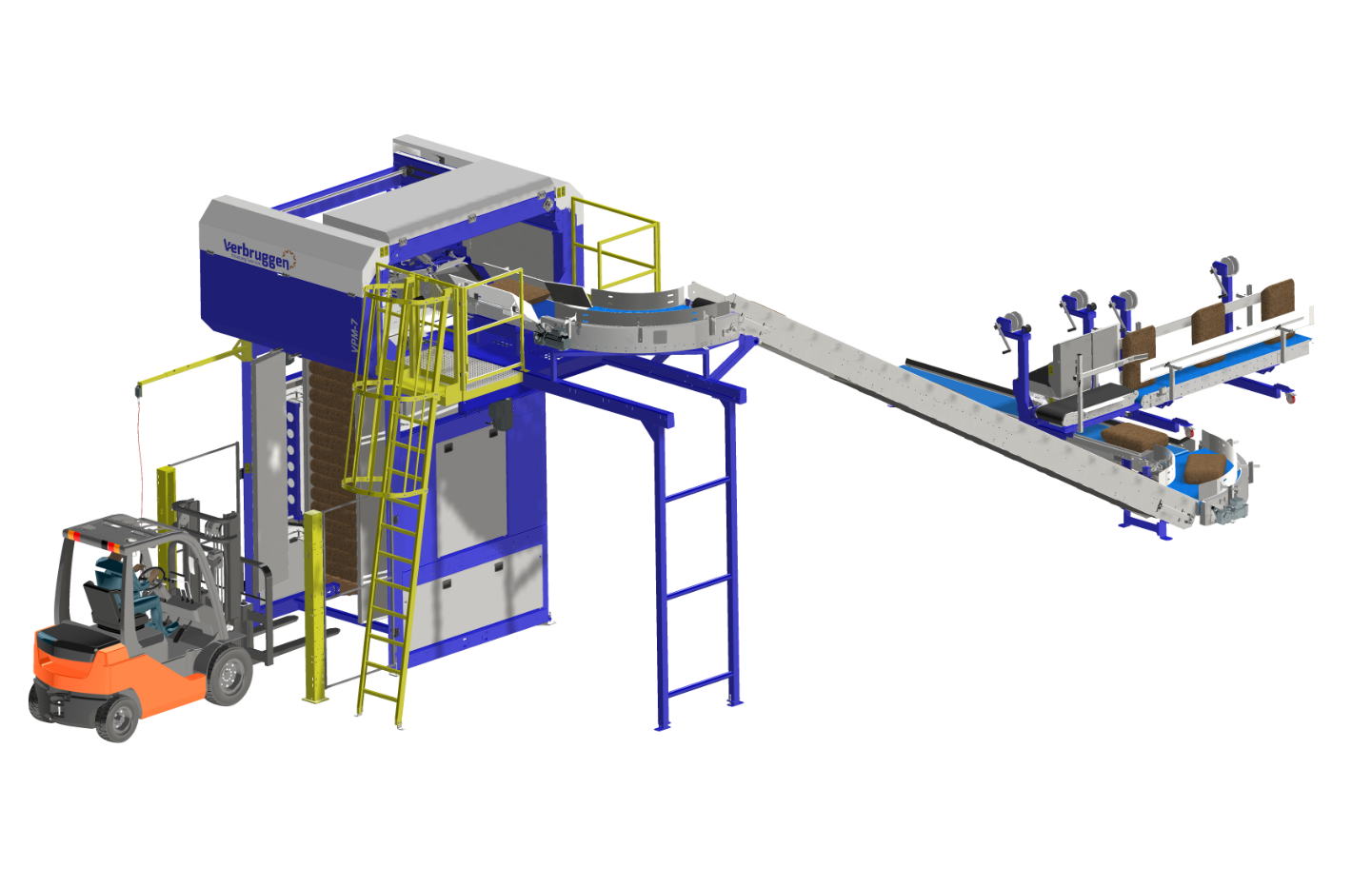

VPM-7

Handling bags and / or boxes

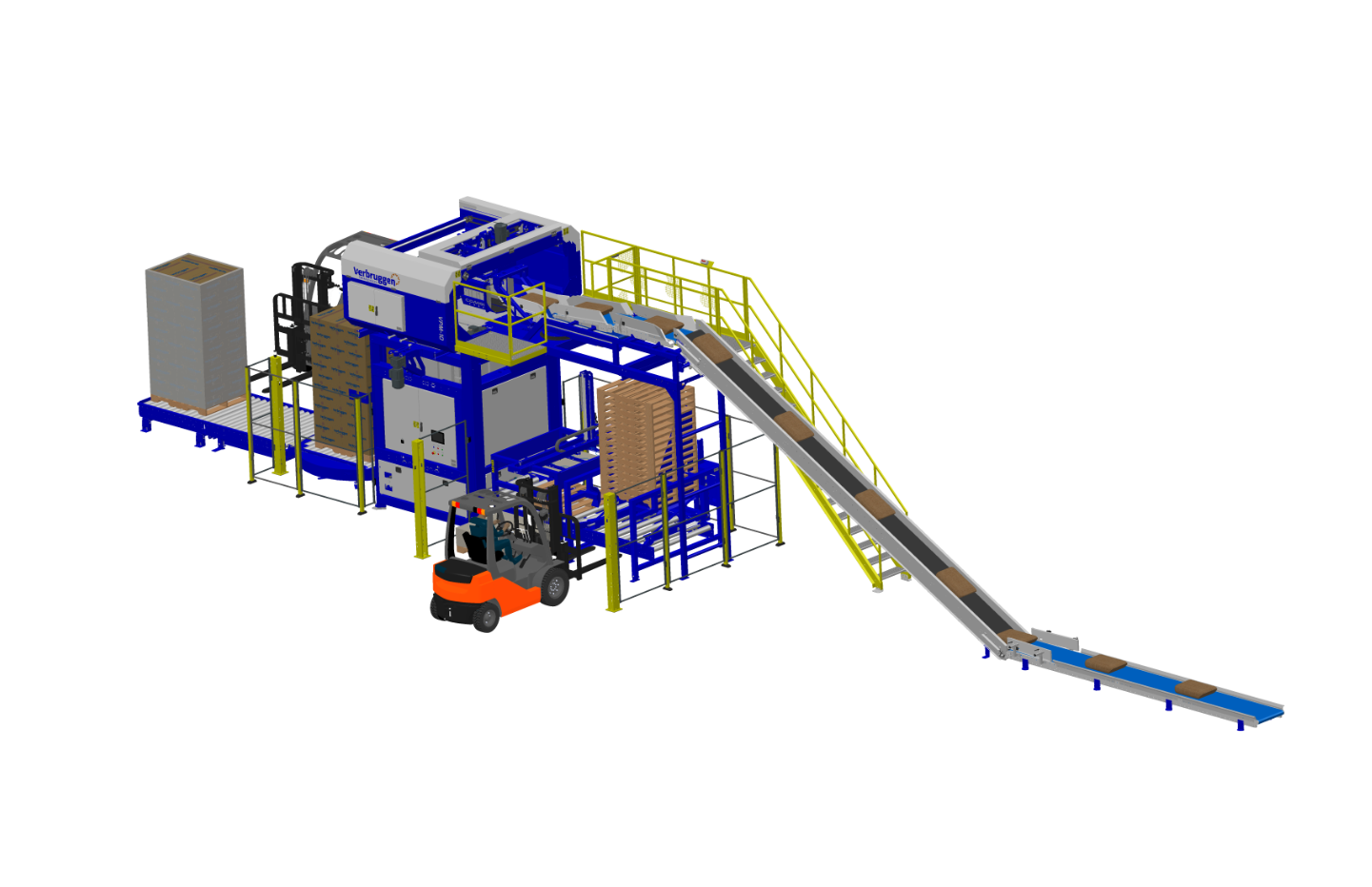

VPM-8

Handling bags and / or boxes

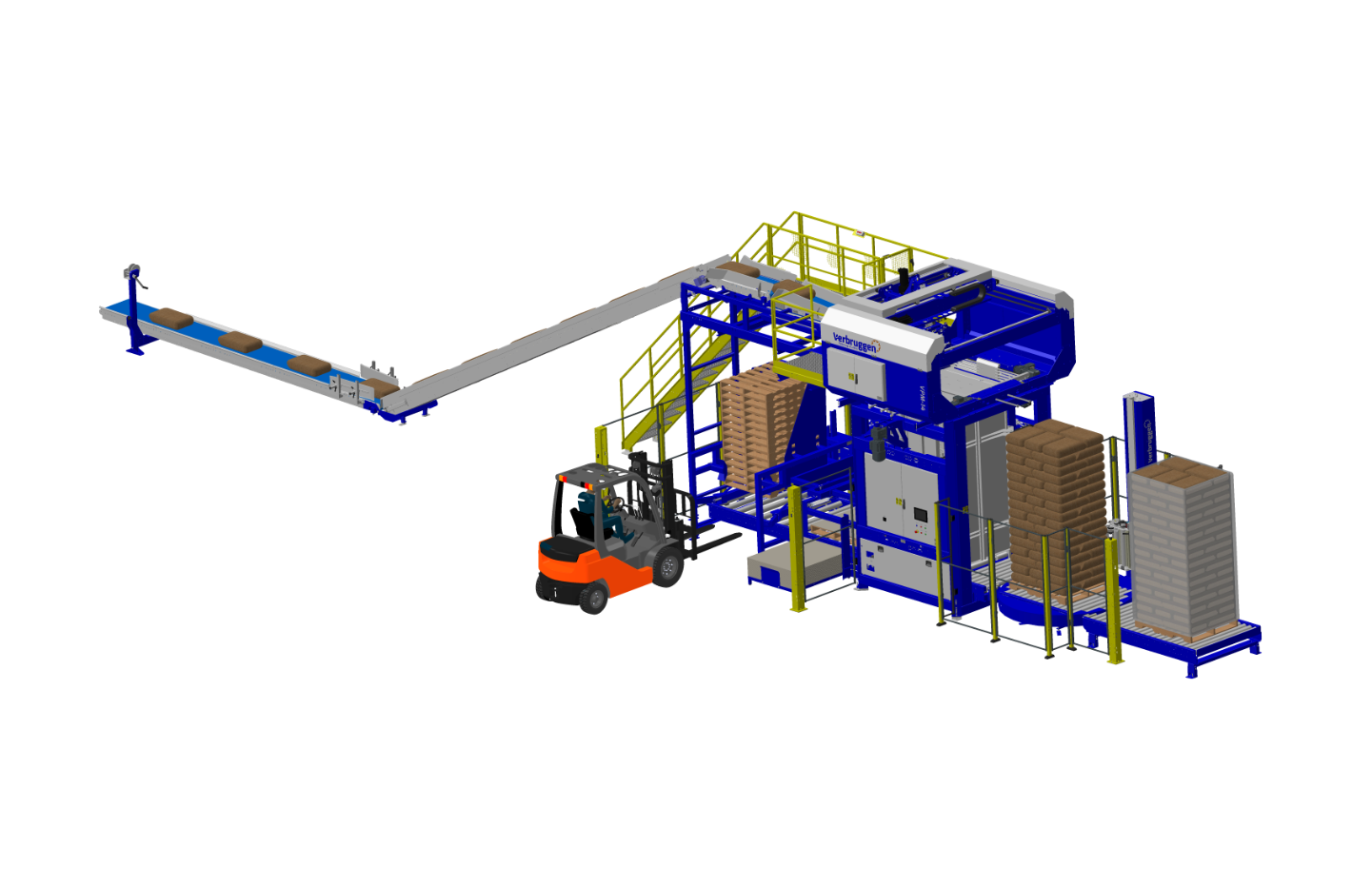

VPM-10

Handling bags and / or boxes

VPM-14

Handling bags and / or boxes

VPM-BL

Handling boxes / cartons / crates / wraps

VPM-ACP

Handling boxes / cartons / crates / wraps

VPM-VHV

Handling boxes / cartons / crates / wraps

Case photos Palletizing in Agriculture – JMB Farming (UK)

Why Choose a Verbruggen Palletizer for Agriculture?

Gentle product handling

Verbruggen palletizers are particularly suitable for agricultural processes because of special features allowing round and irregular shape of products such as potato, onion, carrot and cabbages to be stacked in a compact and tall format up to 2,5 meters.

Flexibility

Verbruggen’s own intelligent software enables the use of 20 possible stacking patterns, which makes it easy for customers to choose the best stacking patterns when palletizing different sizes of bags. It is also possible to combine bags and boxes or stack bags in boxes.

High speed stacking and accuracy

Verbruggen palletizers deliver high quality stacking in a high speed. Automated stacking of bags, crates or boxes from 10 to 40 bags per minute, and up to 120 boxes per minute

Local service availability

Besides our own branch offices in The Netherlands, USA, China and Bangladesh, we have an extended network of partners worldwide offering local service availability.

Good ROI; save labor costs and space

Choosing a Palletizing solution of Verbruggen will not only save labor costs and provide a better and more save working environment. It also saves space in storage and transport. Finally it also reduces product loss due to unstable and damaged stacks. Altogether a healthy investment, and we are more than happy to help calculate your ROI.

FREQUENTLY ASKED QUESTIONS

Palletizing refers to the process of arranging and stacking products on a pallet in a warehouse or manufacturing facility. The goal of palletizing is to create a stable and secure load that can be easily moved and stored using a forklift or pallet jack.

Palletizing can be done manually by workers or by using automated equipment, such as robots or conveyor systems. In a palletizing operation, the products to be palletized are typically brought to a central location, and then they are picked up and arranged on the pallet according to a specific pattern or configuration. The palletized products are then wrapped or secured in place using packaging materials such as shrink wrap or stretch wrap, and labeled with the necessary information for handling and storage.

Palletizing is a key part of many logistics and supply chain systems, as it allows for the efficient and safe handling and storage of products

A palletizing system is a type of or combination of automated equipment used in warehouses and manufacturing facilities to arrange and stack products on pallets. Palletizing systems can include a variety of different components, such as conveyor belts, robots, and packaging machinery, that work together to efficiently and accurately palletize products.

Palletizing systems can be programmed to handle a wide range of products and can work quickly and accurately, reducing the amount of manual labor required in a warehouse or manufacturing facility. They are often used in conjunction with other types of automation equipment, such as conveyor systems and packaging machinery, to improve efficiency and reduce costs

Verbruggen palletizing machines are designed for quality and durability, delivering an incredible stable stack and consistent performance. This exceptional focus on dependability makes Verbruggen the preferred choice of many industry leaders. Additionally, our machines are cutting edge as a result of extensive R&D, meaning that we can stack the most challenging products on the market.

- Latest technology in automation industry 4.0

- Customized solutions designed for your packaging and capacity requirements

- Industry-leading equipment solutions for optimal efficiency and durability

- First-class customer service and after-sales support.

- We can stack any type of products; bags, boxes, crates, cartons, even special product applications..

Verbruggen palletizing machines are designed for quality and durability, delivering an incredible stable stack and consistent performance. This exceptional focus on dependability makes Verbruggen the preferred choice of many industry leaders. Additionally, our machines are cutting edge as a result of extensive R&D, meaning that we can stack the most challenging products on the market.

- Latest technology in automation industry 4.0

- Customized solutions designed for your packaging and capacity requirements

- Industry-leading equipment solutions for optimal efficiency and durability

- First-class customer service and after-sales support.

- We can stack any type of products; bags, boxes, crates, cartons, even special product applications..

Verbruggen palletizing machines are designed for quality and durability, delivering an incredible stable stack and consistent performance. This exceptional focus on dependability makes Verbruggen the preferred choice of many industry leaders. Additionally, our machines are cutting edge as a result of extensive R&D, meaning that we can stack the most challenging products on the market.

- Latest technology in automation industry 4.0

- Customized solutions designed for your packaging and capacity requirements

- Industry-leading equipment solutions for optimal efficiency and durability

- First-class customer service and after-sales support.

- We can stack any type of products; bags, boxes, crates, cartons, even special product applications..

Verbruggen palletizing machines are designed for quality and durability, delivering an incredible stable stack and consistent performance. This exceptional focus on dependability makes Verbruggen the preferred choice of many industry leaders. Additionally, our machines are cutting edge as a result of extensive R&D, meaning that we can stack the most challenging products on the market.

- Latest technology in automation industry 4.0

- Customized solutions designed for your packaging and capacity requirements

- Industry-leading equipment solutions for optimal efficiency and durability

- First-class customer service and after-sales support.

- We can stack any type of products; bags, boxes, crates, cartons, even special product applications..

Verbruggen palletizing machines are designed for quality and durability, delivering an incredible stable stack and consistent performance. This exceptional focus on dependability makes Verbruggen the preferred choice of many industry leaders. Additionally, our machines are cutting edge as a result of extensive R&D, meaning that we can stack the most challenging products on the market.

- Latest technology in automation industry 4.0

- Customized solutions designed for your packaging and capacity requirements

- Industry-leading equipment solutions for optimal efficiency and durability

- First-class customer service and after-sales support.

- We can stack any type of products; bags, boxes, crates, cartons, even special product applications..

Palletizing operation is the process of arranging and stacking products on a pallet in a warehouse or manufacturing facility.

What is the goal of the palletizing operation?

The goal of palletizing is to create a stable and secure load that can be easily moved and stored using a forklift or pallet jack.

Palletizing operations can be done manually by workers or by using automated equipment, such as robots or conveyor systems. In a palletizing operation, the products to be palletized are typically brought to a central location, and then they are picked up and arranged on the pallet according to a specific pattern or configuration. The palletized products are then wrapped or secured in place using packaging materials such as shrink wrap or stretch wrap, and labeled with the necessary information for handling and storage.

Palletizing operations are a key part of many logistics and supply chain systems, as they allow for the efficient and safe handling and storage of products

Inline palletizing is a method of arranging products on a pallet where the products move along a production line. This can be done either manually or by a palletizer. The benefits of Inline palletizing depends on the specific needs of the production or warehouse.

What is an inline palletizing machine?

An inline palletizing machine automatically stacks products on pallets as they move through the inline palletizing system along a conveyor or production line. The inline palletizing system uses special equipment, such as robotic arms or automated palletizers, to accurately place products on the pallets according to predetermined patterns or configurations.

When to use inline palletizing?

Inline palletizing machine is often used when products are produced at a high rate and need to be quickly and efficiently palletized for shipping or storage. It can also be used to improve the accuracy and consistency of the palletizing process because palletizers, robots or automated systems can be programmed to place products on the pallet in a specific pattern or configuration. Inline palletizing can be more efficient and cost-effective than traditional manual palletizing methods, especially for large volumes.

Palletizing products is the process of arranging and stacking products on a pallet, done in a manufacturing or warehouse facility. The goal of palletizing products is to create a stable and secure load that can be easily moved and stored using a forklift. Palletizing products can be done manually or by using machinery, such as palletizers, palletizing robots or conveyor systems.

In a palletizing operation, the products to be palletized are typically brought to a central location, and then they are picked up and arranged on the pallet according to a specific pattern or configuration. The palletized products are then wrapped or secured in place using packaging materials such as shrink wrap or stretch wrap, and labeled with the necessary information for handling and storage.

A palletizing robot -or palletizer robot- is a type of industrial robot (robotic machine) that is used to stack and unstack items on pallets in a warehouse or manufacturing environment. These robots are typically equipped with a gripper or suction cup to pick up items, and are programmed to arrange them in a specific pattern or configuration on a pallet.

Palletizing robots and palletizer machines can be the same thing. A typical difference can be the use of a robotic arm versus the use of a manipulator. In the vast majority of cases, a palletizer with a manipulator achieves a higher stacking speed than a robotic arm.

Palletizing robots can work quickly and accurately, and can be used to handle a wide range of products, including boxes, bags, and other types of packages. They are often used in conjunction with other automation equipment, such as conveyor systems and packaging machinery, to improve efficiency and reduce the amount of manual labor required in a warehouse or manufacturing facility