What is Inline Palletizing?

Inline palletizing is a method of arranging products on a pallet where the products move along a production line. This can be done either manually or by a palletizer. The benefits of Inline palletizing depend on the specific needs of the production or warehouse

What is an inline palletizing machine?

An inline palletizing machine automatically stacks products on pallets as they move through the inline palletizing system along a conveyor or production line. The inline palletizing system uses special equipment, such as robotic arms or automated palletizers, to accurately place products on the pallets according to predetermined patterns or configurations.

When to use inline palletizing?

Inline palletizing machine is used when products are produced at a high rate and/or high speed, and need to be quickly and efficiently palletized for shipping or storage. It can also used to improve the accuracy and consistency of the palletizing process because palletizers, robots or automated systems can be programmed to place products on the pallet in a specific pattern or configuration.

Inline palletizing can be more efficient and cost-effective than traditional manual palletizing methods, especially for large volumes.

Inline palletizer machine in different industries

There are several examples of inline palletizing systems used in various industries. Some common examples include:

Inline palletizing in Food and Beverage Industry

Inline palletizing is used to stack packaged food items, beverages, bottles, cans, and other products onto pallets for efficient storage and transportation. It ensures the products are securely arranged and ready for distribution.

Inline palletizing in Pharmaceutical Industry

In the pharmaceutical sector, inline palletizing is employed to palletize pharmaceutical products, such as bottles, boxes, blister packs, and cartons. It ensures accurate and consistent stacking, minimizing the risk of damage during handling and transportation.

Inline palletizing in Manufacturing Industry

Inline palletizing finds application in manufacturing operations. Where it is used to palletize products such as automotive parts, electronic components, appliances, and other manufactured goods. It optimizes the packaging process and facilitates smooth material flow.

Inline palletizing in E-commerce and Retail

In e-commerce and retail warehouses, inline palletizing is used to stack products, including boxes, parcels, and other packaged items, onto pallets for order fulfillment. It enables efficient handling and streamlines the shipping process.

Inline palletizing in Building Materials Industry

Inline palletizing is utilized in industries dealing with building materials such as bricks, tiles, bags of cement, lumber, and roofing materials. It ensures proper stacking and organization of heavy and bulky items for easier storage and transportation.

These examples highlight how inline palletizing is employed across various sectors to automate the stacking and arrangement of different products onto pallets. Improving efficiency and optimizing logistics processes

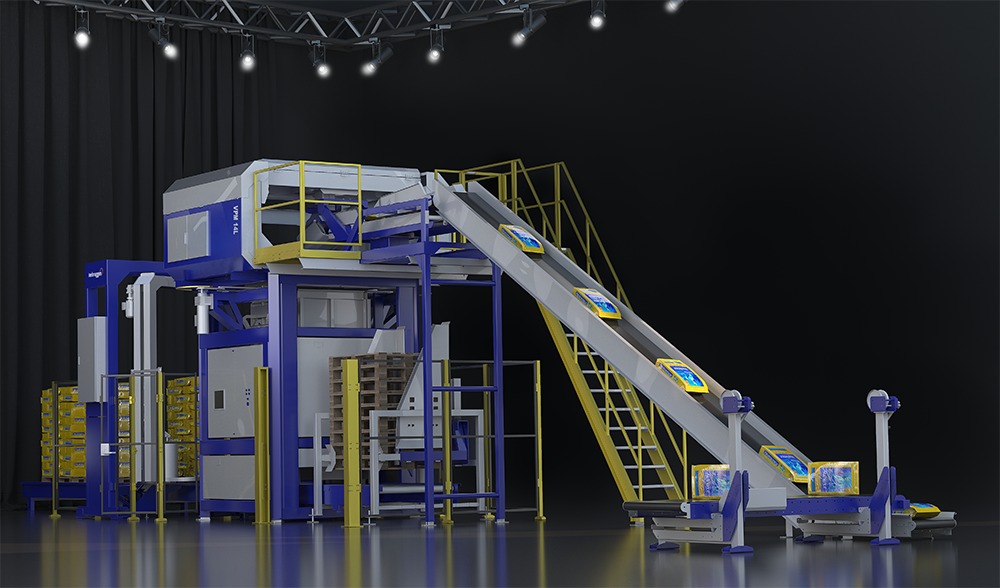

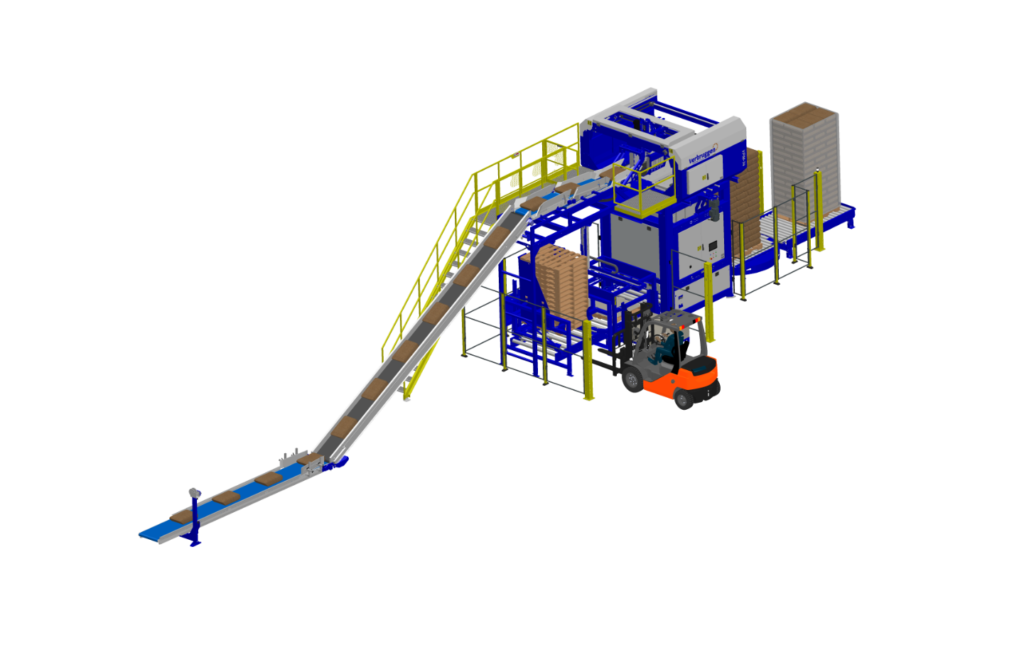

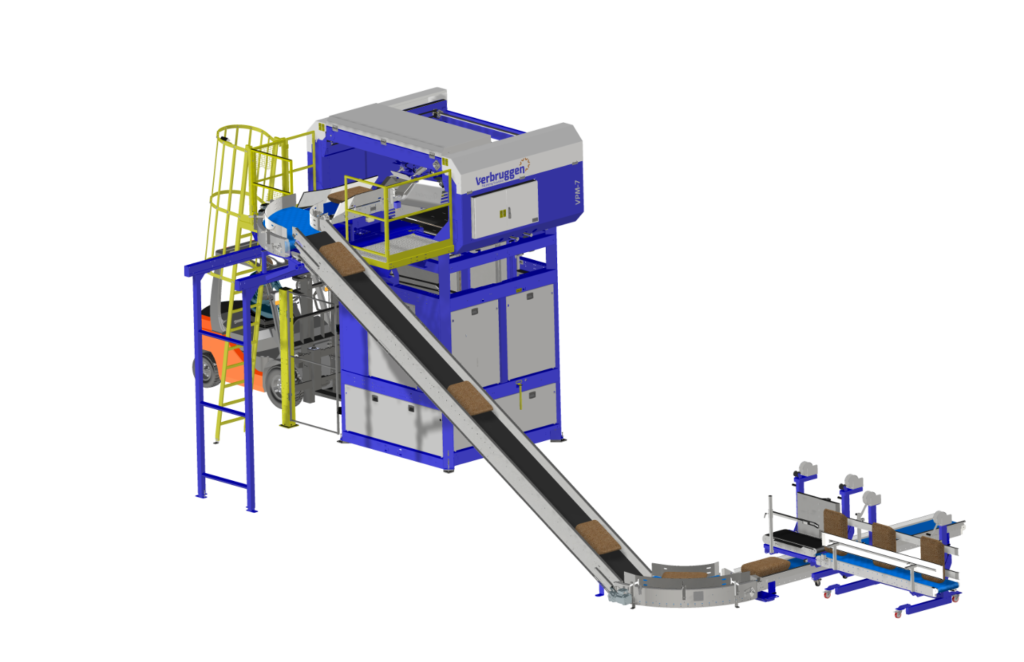

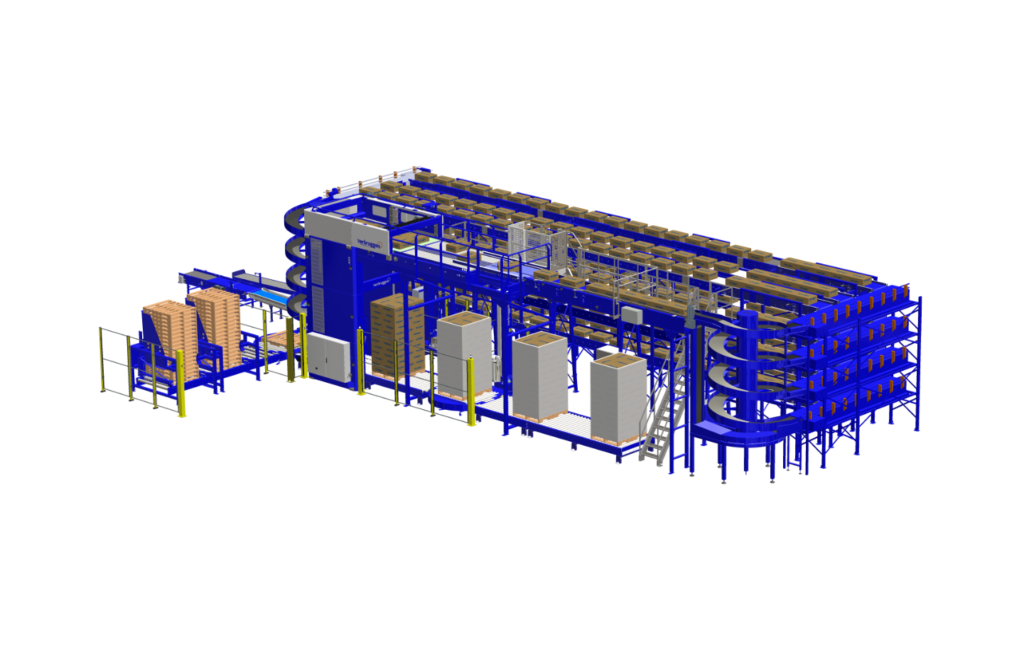

Palletizing with Verbruggen palletizing machines

Verbruggen is a well-known manufacturer of palletizer machines, and they offer inline palletizing solutions among their range of products. Verbruggen palletizer machines are designed to automate the process of stacking products onto pallets. Providing efficient and accurate palletizing solutions for various industries.

Verbruggen’s inline palletizing machines utilize a flexible manipulator

The manipulator -instead of robotic or mechanical arms- picks up products coming from a conveyor system or production line, and precisely place them onto pallets according to predefined patterns or configurations. These machines are integrated with advanced technologies, such as sensors, vision systems, and software controls, to optimize the palletizing process and enhance productivity.

Verbruggen’s palletizer machines are known for their versatility and ability to handle a wide range of product types, sizes, and weights.

They offer customizable solutions to meet the specific palletizing requirements of different industries, providing reliable and efficient inline palletizing solutions

Interested in what palletizing can do for your situation?

Discover our different palletizer machines or get in touch for more information. See all contact options at our contactpage (click). We are happy to help you.