Discover the Palletizers & Palletizing machines by Verbruggen

Do you need quick, efficient & perfectly stacked products on pallets or sheets? Reducing labor costs & downtime, while optimizing loading space at the same time? In that case you found your

match with Verbruggen Palletizing machines. These palletizers provide a significant increase

in productivity, improve operations, reduce costs, and create a safer and more efficient

workplace.

Overview Palletizing Machines

Discover Our Various Palletizers

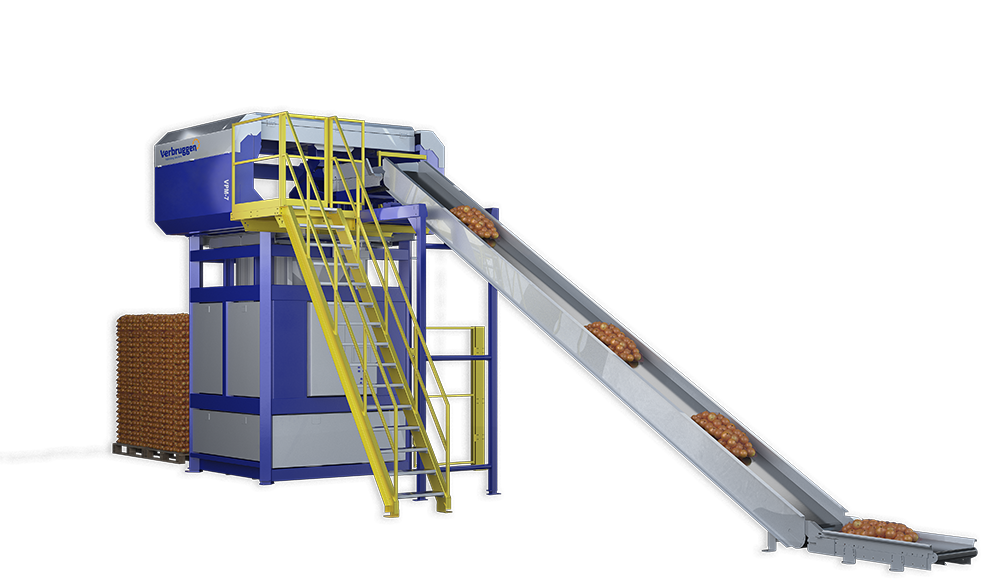

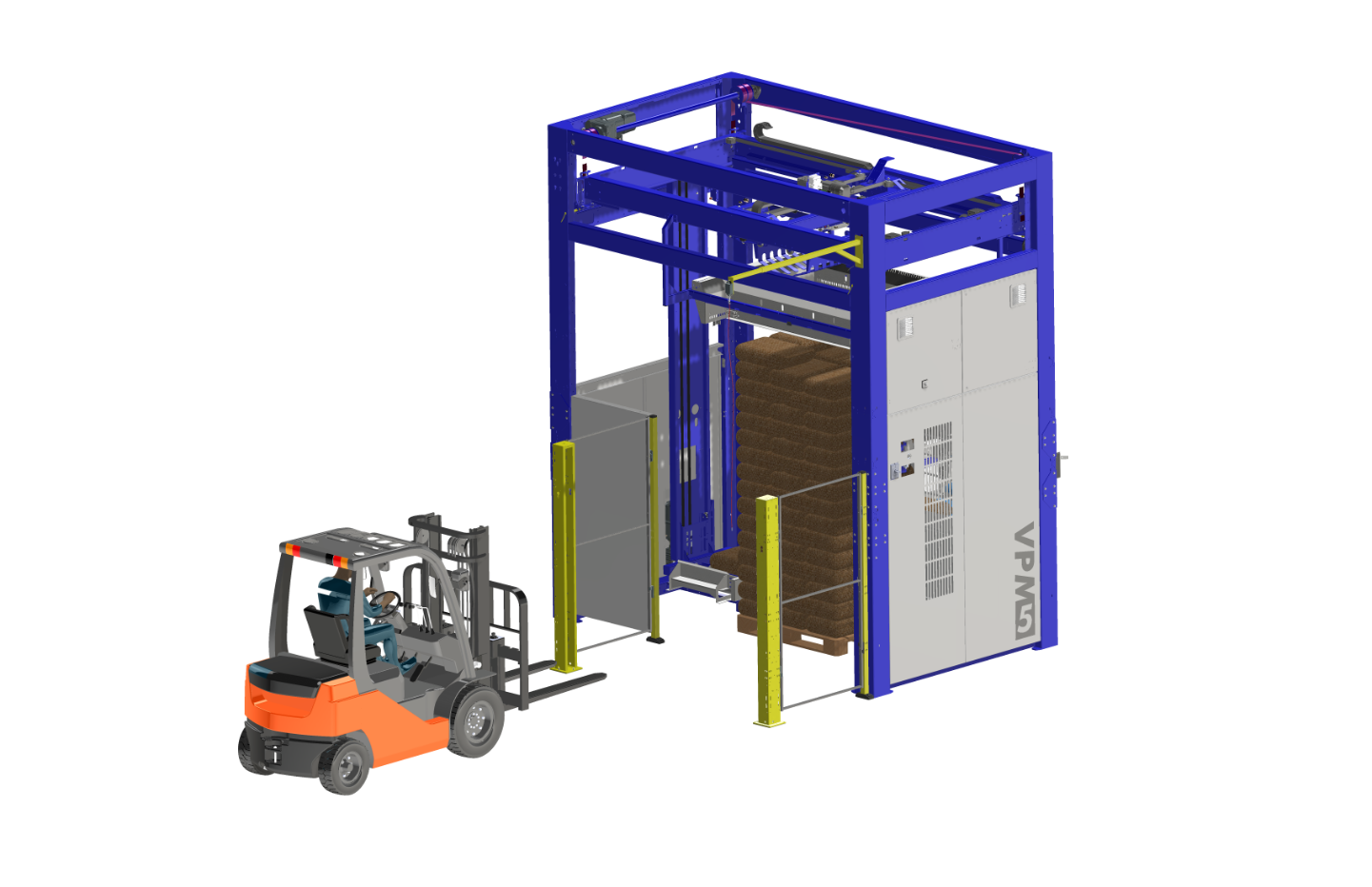

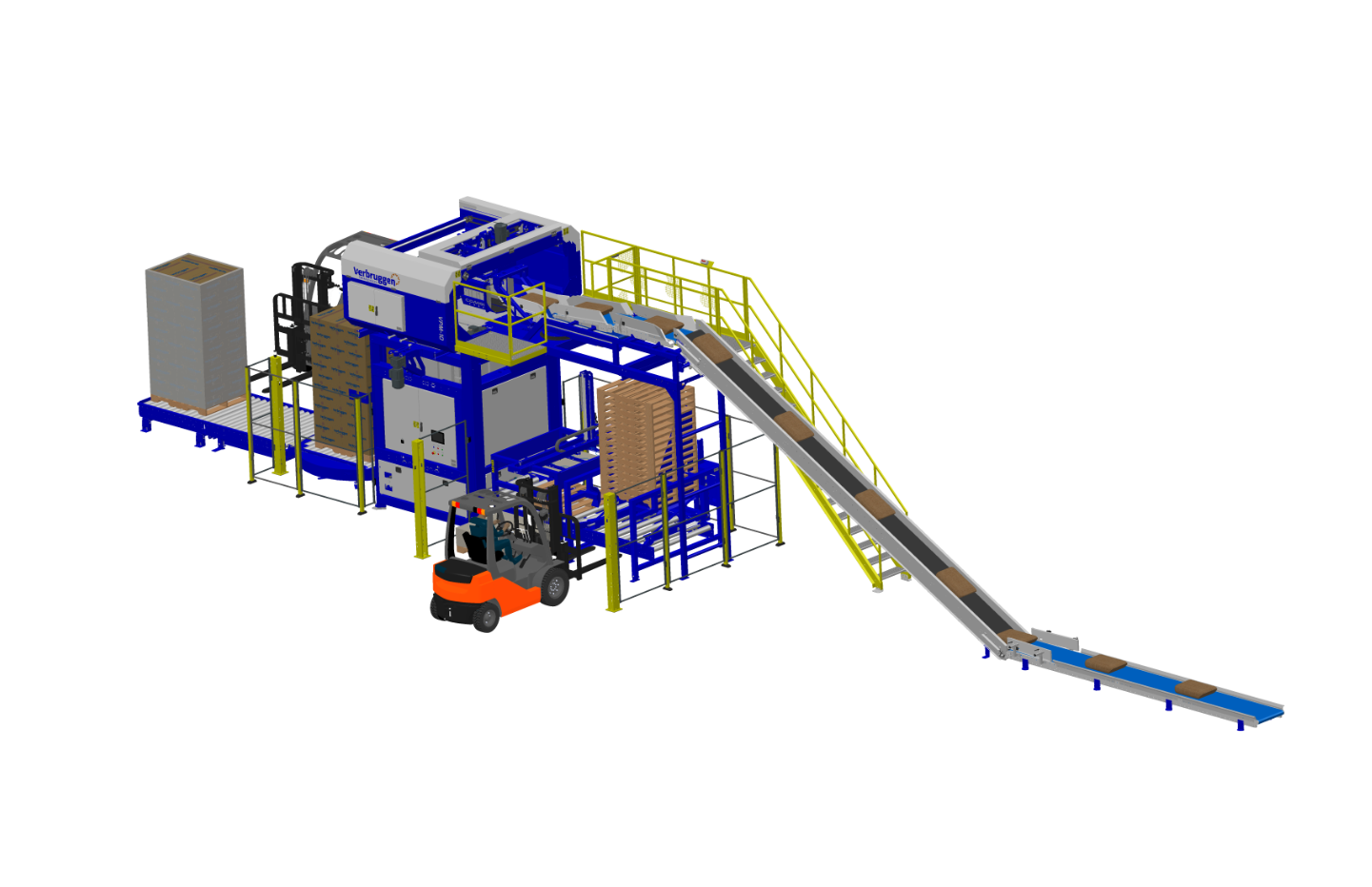

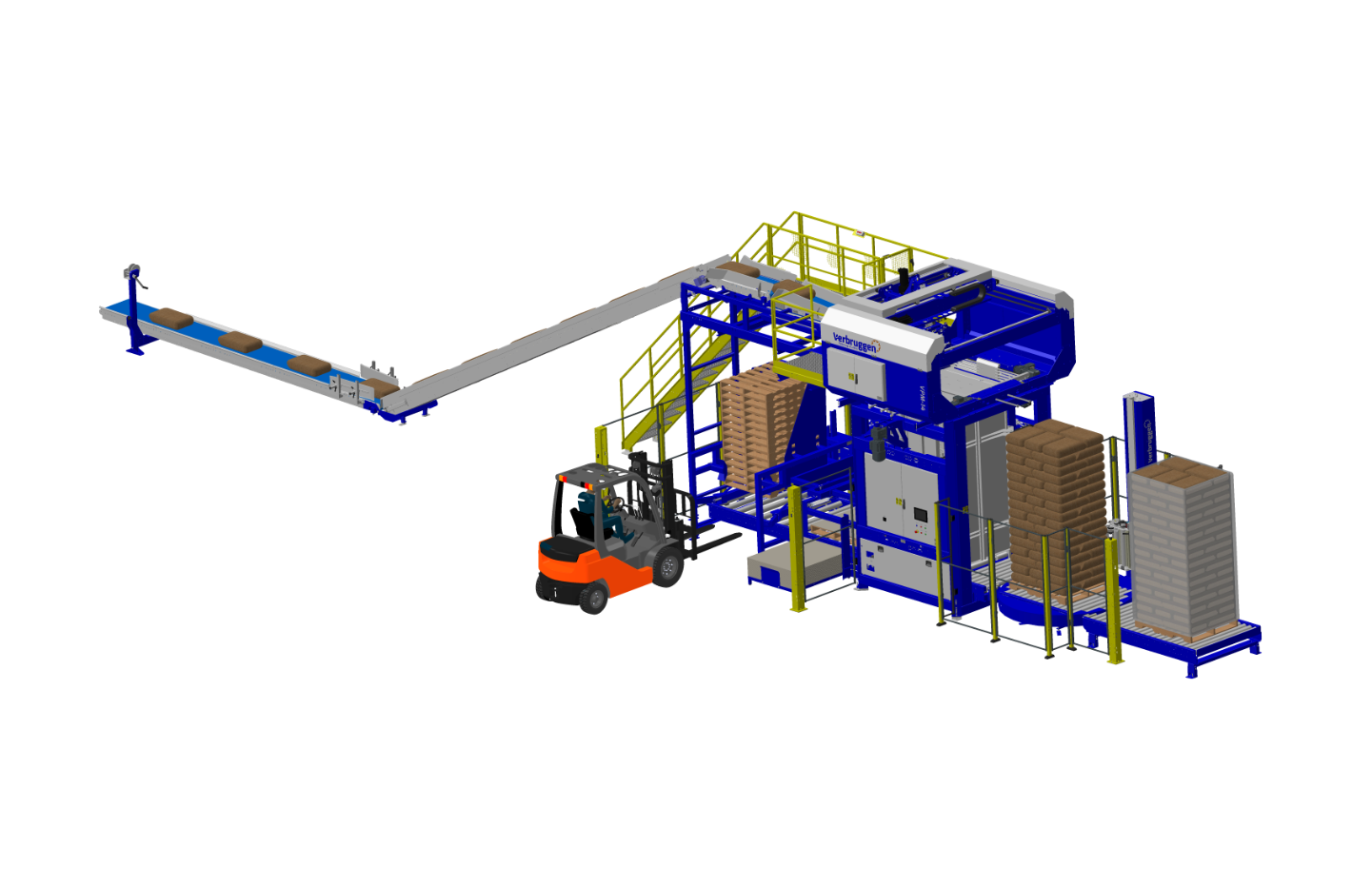

VPM-5

Handling bags

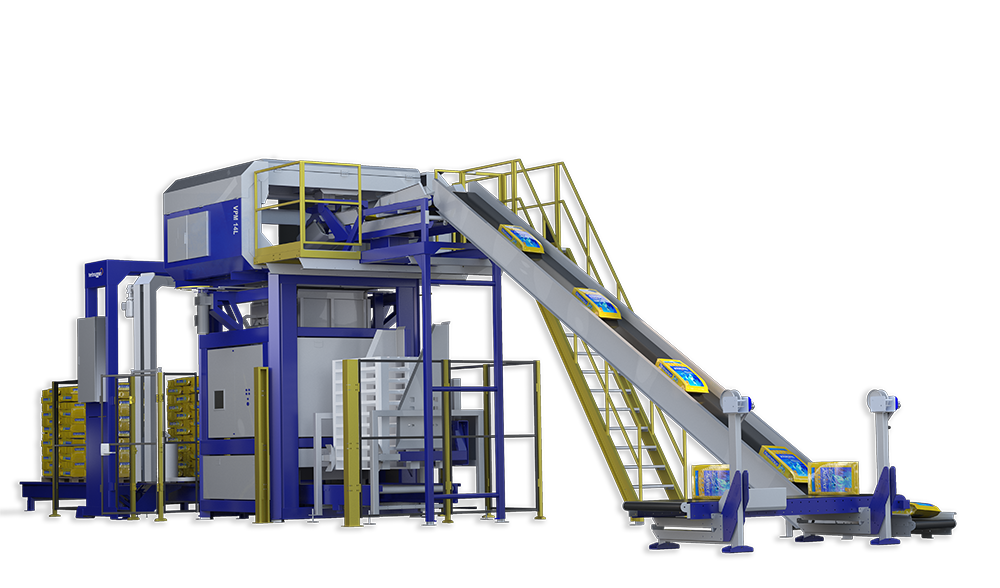

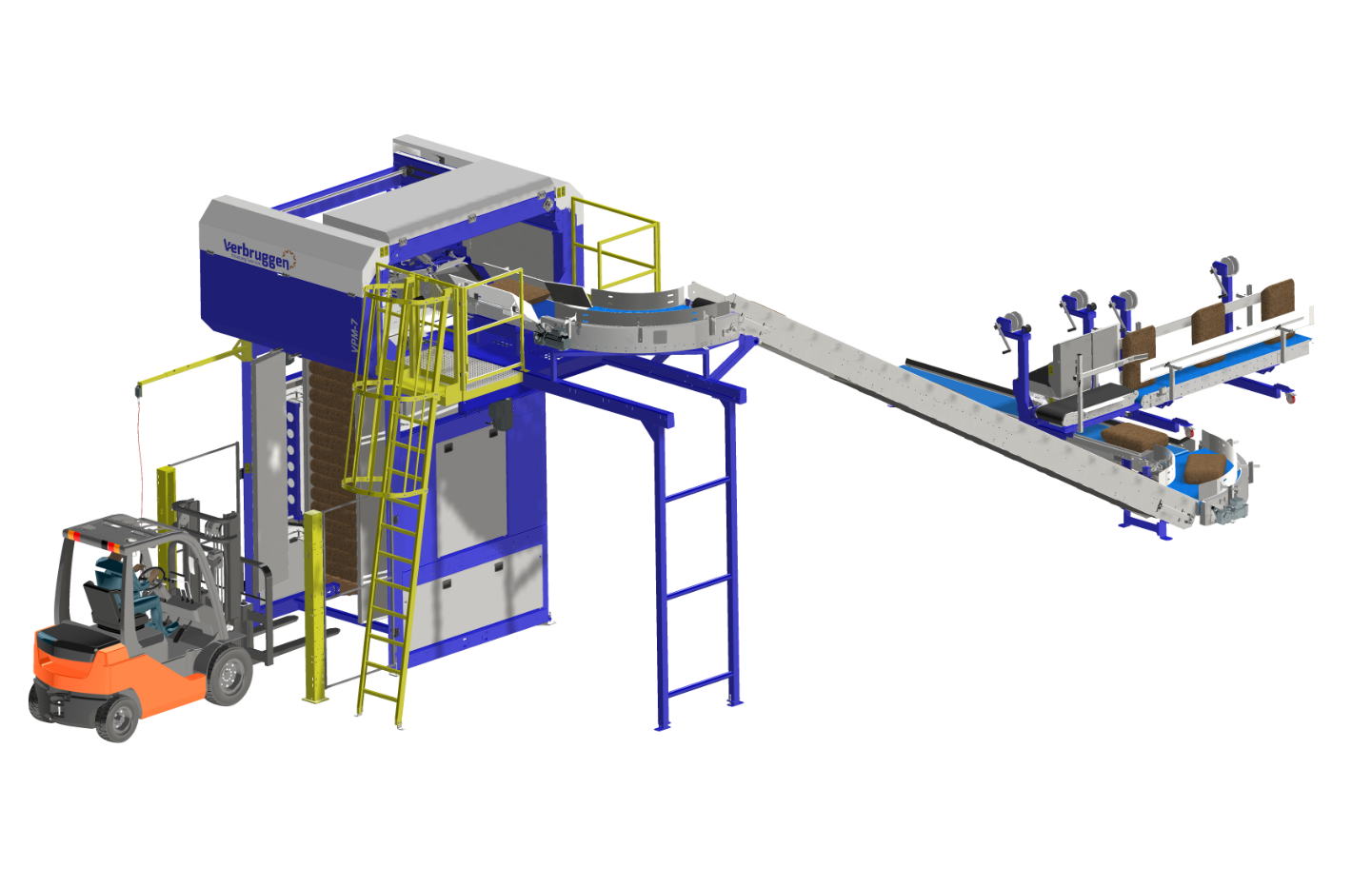

VPM-7

Handling bags and / or boxes

VPM-8

Handling bags and / or boxes

VPM-10

Handling bags and / or boxes

VPM-14

Handling bags and / or boxes

VPM-BL

Handling boxes / cartons / crates / wraps

VPM-ACP

Handling boxes / cartons / crates / wraps

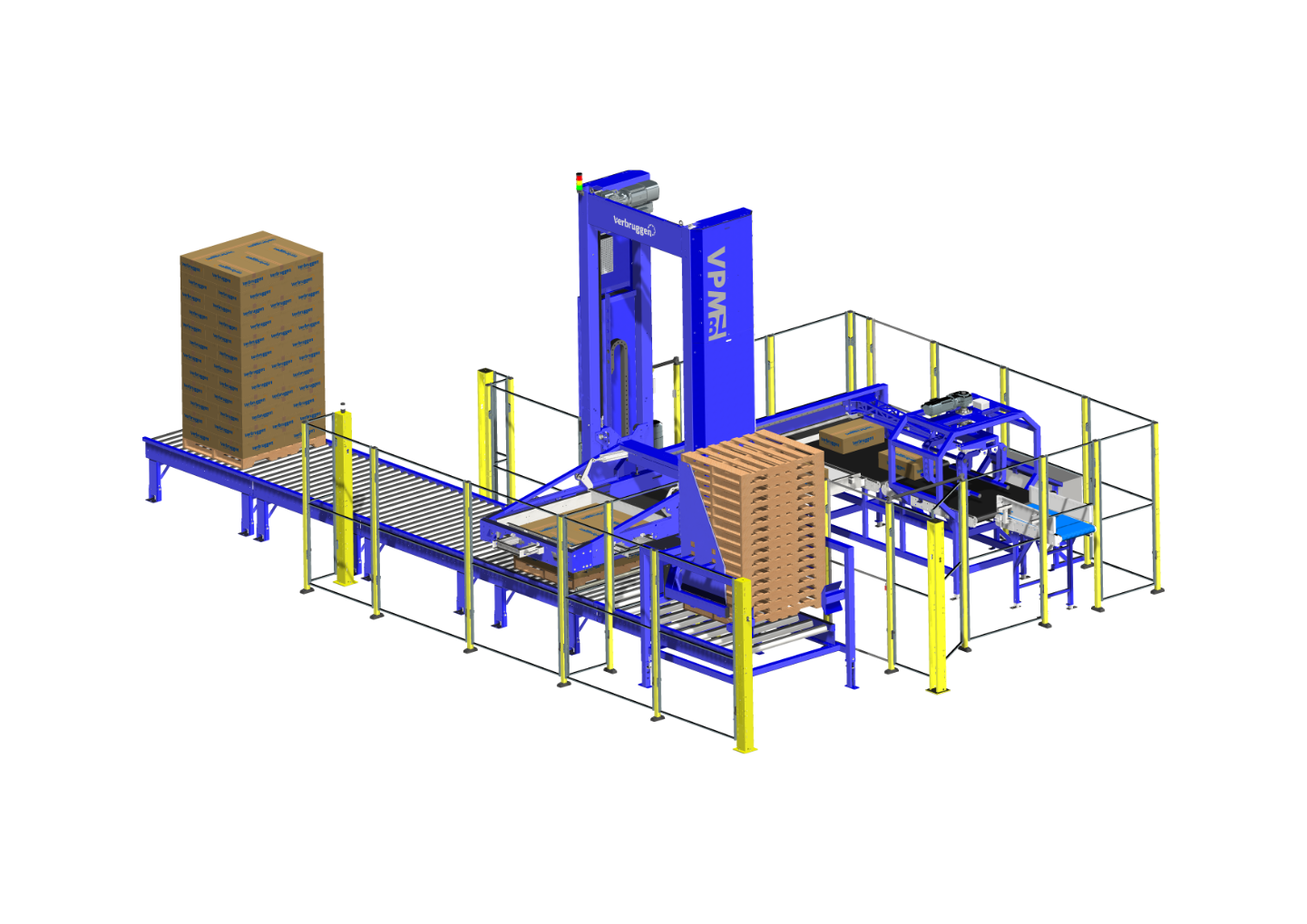

VPM-VHV

Handling boxes / cartons / crates / wraps

Discover our palletizing machines for bags, boxes, crates, wraps and cartons

Our series of Palletizing machines (VPM) offer various options in automation level, rate and packagings to stack bags, boxes, crates, wraps, and cartons.

Discover our various fully automatic and semi-automatic palletizers, with precise product stacking capabilities at any speed. We make sure you will always get

the palletizer that fits your company best. Finally, you can achieve the perfectly stacked pallet result that you have been looking for.

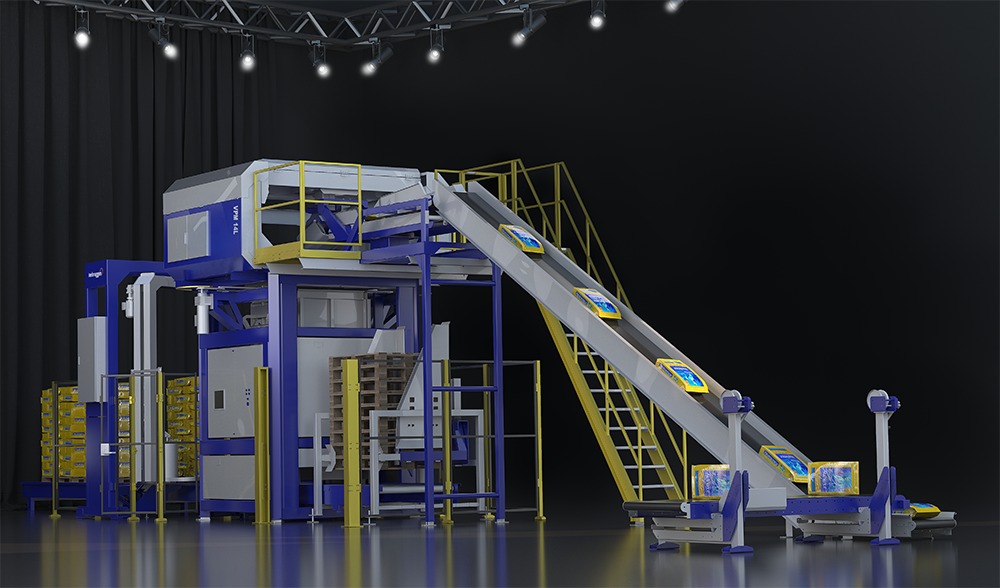

Automated bag palletizing machines

Robotic bag palletizers are automatic machines used to stack and organize bags of various dimensions and shapes onto a pallet.

Verbruggen’s bag palletizers are:

● Palletizer VPM-4-5

● Palletizer VPM-7

● Palletizer VPM-8

● Palletizer VPM-10

● Palletizer VPM-14

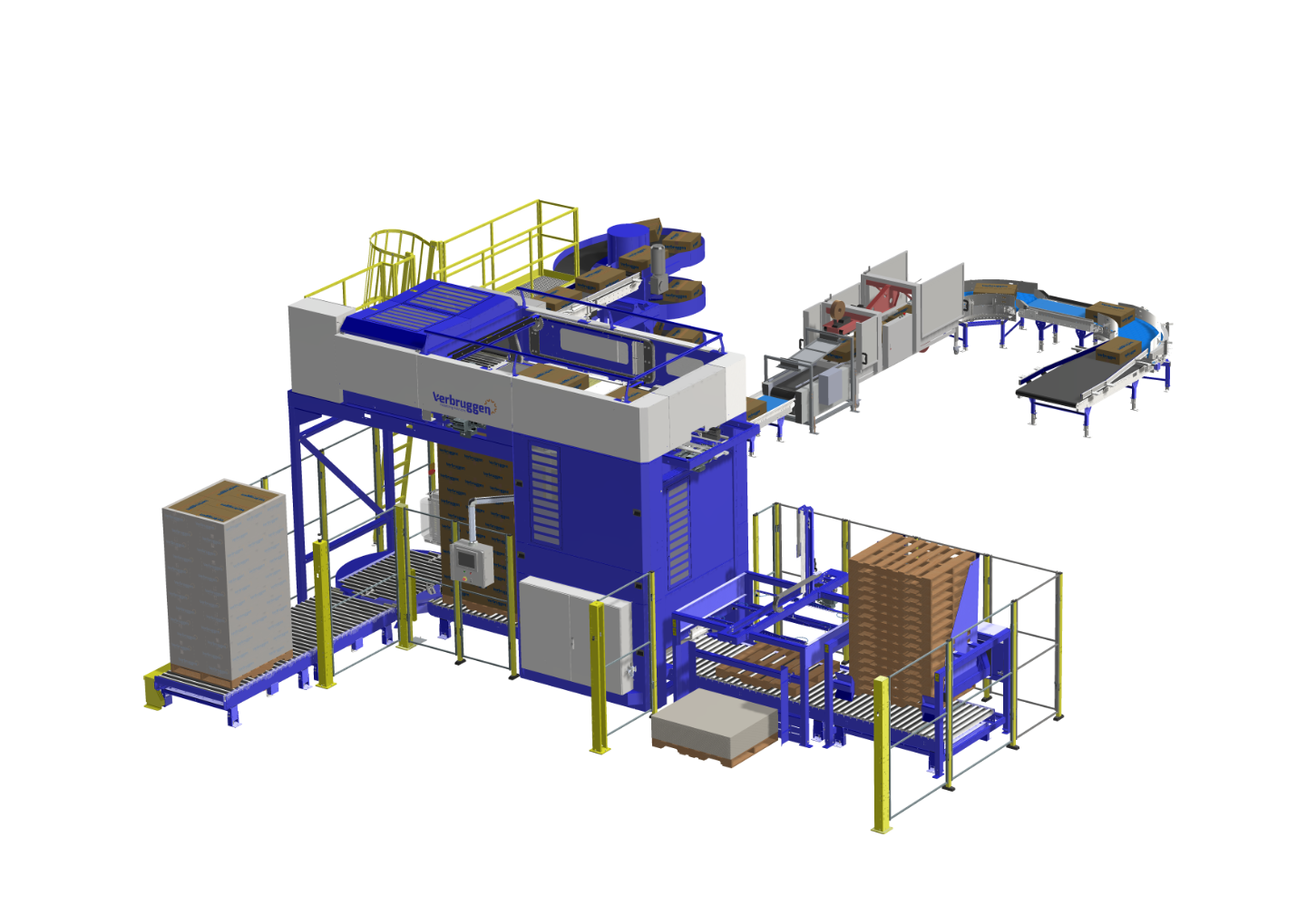

Box & Carton Palletizing Machines

A box & carton palletizer is a machine with robotic capabilities that is

specifically designed to stack and organize boxes, crates, wraps, and cartons

onto pallets. Verbruggen’s box & carton palletizers are:

● Palletizer and Wrapping machine combinations for a streamlining

process

● Palletizer VPM-BL

● Palletizer VPM-ACP

● Palletizer VPM-VHV

Palletizer and Wrapping machine combinations for a streamlining process

Wrapping machines are commonly used additionally to a palletizer that prepares your palletized products for transportation. Our machines are designed to prevent external damage and provide stability by using a variety of wrapping materials tailored to your product’s specific features:

● Film: protects products from environmental factors such as humidity and dust.

● Mesh: allows fresh produce to breathe during transportation.

● Combination of mesh and paper: shields products from UV light exposure

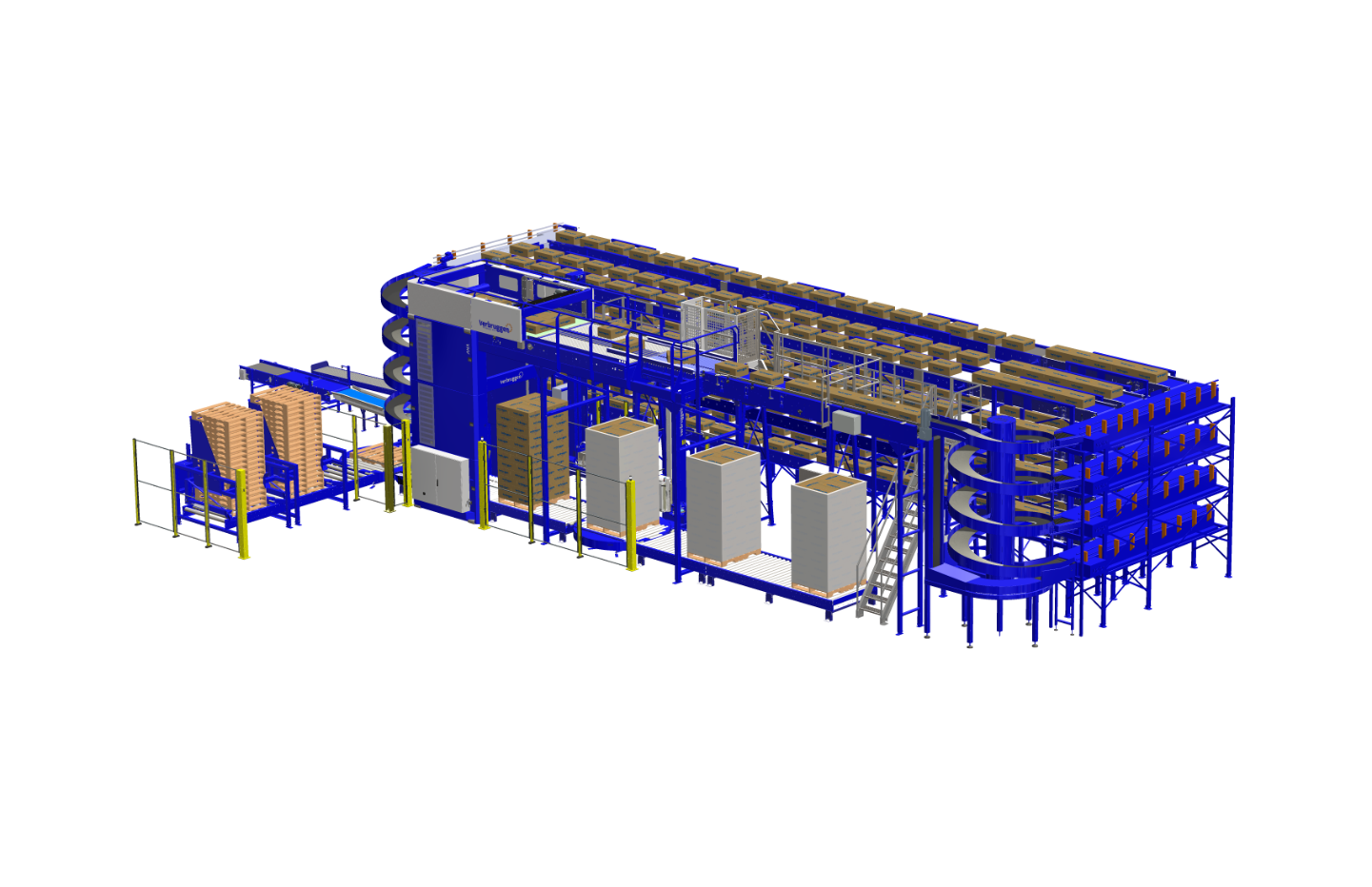

Automatic palletizer systems: robotic efficiency for your business

A robotic palletizing system is a highly automated solution that uses a robotic arm to stack and arrange packagings onto pallets. This type of system offers several advantages overtraditional (conventional) palletizers, including increased flexibility, speed, and efficiency.

Robotic palletizing systems can handle a wide range of products.

Including bags, boxes, crates, wraps, cartons and more, and can stack them in a variety of patterns to optimize space utilization and stability. The robotic arm can also be programmed to handle products with varying dimensions, shapes, and weights, making them ideal for industries with multiple product lines.H3: In addition, robotic palletizing systems can operate at high speeds

In addition, robotic palletizing systems can operate at high speeds

Allowing for fast and efficient stacking of products. They can also be easily integrated with other equipment, such as conveyors and wrapping machines, to create a fully automated production line.

Overall, a robotic palletizing system is a valuable investment for industries that require high-speed and flexible palletizing solutions to improve efficiency, reduce labor costs, and optimize production processes.

How does a palletizer work?

A palletizer is a machine that automatically stacks and arranges products onto pallets. The main function of a palletizer is to consolidate products into a unit load for efficient storage and transportation.

The palletizer can handle a wide variety of products, such as bags, boxes, crates, wraps and cartons, and can stack them in a range of patterns to optimize space utilization and stability. It can also be programmed to handle different packaging dimensions and weights, making it ideal for industries with diverse product lines.

Overall, a palletizer is an essential piece of equipment for industries that require efficient and reliable palletizing solutions to optimize their production processes and improve their efficiency.

Advantages of using palletizer machines

Using a palletizer machine offers several advantages over manual palletizing, including increased efficiency, improved safety, and reduced labor costs. The machine can operate at high speeds, allowing for fast and efficient stacking of packagings, and can also be integrated with other equipment, such as wrapping machines and conveyors, to create a fully automated production line.

Overall, a palletizer machine is an essential piece of equipment for industries that require efficient and reliable palletizing solutions to optimize their production processes and improve their efficiency.

What is a Palletizing machine?

A Palletizing machine is a type of equipment used to stack and arrange products onto pallets in a uniform and efficient manner. The main purpose of a palletizer machine is to consolidate products into a unit load for easy storage and transportation.

A Palletizing machine can stack a wide range of different packagings and products.

Such as bags, boxes, crates, wraps, cartons, and more. The stacking is possible in various patterns to optimize space utilization and stability. The machine can also be programmed to handle different product dimensions, shapes, and weights, making it ideal for industries with multiple product lines.

Different types of palletizer machines

Palletizer machines come in different types, including conventional palletizers, robotic palletizers, and hybrid palletizers. Conventional palletizers use mechanical arms or a suction cup to pick up products and stack them onto pallets, while robotic palletizers use robotic arms to handle packagings with greater precision and flexibility. Hybrid palletizers, as the name suggests, combine the features of both conventional and robotic palletizers.

Palletizing machines in a palletizing process

A palletizing process typically involves the use of a palletizer, which is a machine that is designed to stack and arrange bags, boxes, crates, wraps, cartons or other packagings onto a pallet. The process begins with the packagings being transported to the palletizer, either manually or

automatically. Once the products are in position, the palletizer uses a robotic arm or other mechanism to lift the products and stack them onto the pallet in a preprogrammed pattern.

The palletizer can also be equipped with a wrapping machine, which applies stretchfilm, mesh, or other materials to secure the packagings to the pallet. Once the pallet is fully loaded and wrapped, it is removed from the palletizer and moved to a storage area or loaded onto a truck or railcar for transportation.

The specific steps in a palletizing process can vary depending on the type of products being handled, the production requirements, and the level of automation used in the process. However, the general goal is to efficiently and securely stack and organize products onto a

pallet for transportation and storage.

Palletizers for various Industries

A palletizer machine is a valuable addition for various industries because of the efficient and accurate way it can stack and arrange packagings. Verbruggen offers palletizers for the following industries:

● Agricultural industry

● Feed industry

● Food industry

● Nonfood industry

Customized Palletizing machine Solutions

Find the perfect palletizer for your needs with our customized design

options that include a wide range of possibilities and features, such as a customized layout, semi or fully-automatic operation, wrapping machines, and additional equipment like strapping machines, evenflow units, and check weighers. Do you require a machine that can palletize both bags and boxes/crates/wraps/cartons? No problem, our dual-purpose Combi-Manipulator is equipped with hands-free programming selection.

Thanks to continuous software and design improvements, our palletizers boast low maintenance costs, reliable equipment operation, and a very long service lifecycle. We also offer Remote Assistance software, which allows our support team to monitor your machine from anywhere in the world. Our service team is available 24/6 to ensure the highest possible uptime for your machine.

FREQUENTLY ASKED QUESTIONS

Of course! We are committed to giving you all the information you need to make your decision. We have about 1500 machines running worldwide, with excellent customer relationships, and references. Fill out the form and we will schedule a visit for you to a Verbruggen machine in your area.

Verbruggen palletizers are made for heavy-duty agricultural and industrial use. Many of our machines are used daily, lasting in excess of 25 years, stacking more than 25 million packagings. A palletizing system is a type of or combination of automated equipment used in warehouses and manufacturing facilities to arrange and stack products on pallets. .

To ensure that your production process runs smoothly, it is essential that your machines are always reliable and ready for operation. That’s why we have a team of highly skilled service technicians who provide support worldwide to our customers, ensuring that their machines are always in top operating condition and ready to receive and stack products. .