Palletizing Solutions for Food Industry

In the food industry, our palletizing solutions cater specifically to products packed or transported in bags, crates, and boxes. Our expertise lies in handling a wide range of food products, including grains, rice, corn, sugar, salt, coffee, cocoa, cereals, flour, milk powder, bakery materials, and more. With Verbruggen palletizers, you can confidently palletize bags weighing anywhere from 2.5 kg (5 lbs) to 75 kg (165 lbs), as well as various sizes of boxes and bags within boxes.

Our machines are designed to accommodate the specific packaging needs of the food industry, ensuring efficient and precise palletizing for your products.

Product stacking in Food Industry

Stacking Boxes in Food Industry

Palletizing solutions, including machines, are widely used in the food industry for storage and transport of crops. These automated systems stack boxes onto pallets, facilitating easy movement with forklifts. Implementing palletizing solutions brings numerous benefits.

Pallet Machines can handle various box sizes, ensuring versatility for different products. Integration with warehouse management systems optimizes logistics operations, enhancing overall efficiency.

Automated palletizing provides a valuable and cost-effective method for storing and transporting crops in the food industry. With stable unit loads, they offer increased efficiency, reduced labor costs, improved safety, and customizable options to meet specific business requirements.

Stacking Bags in Food Industry

Stacking bags is crucial in the food industry, particularly for the storage and transportation of crops like rice, sugar, and cocoa. These crops are packaged in stackable bags providing protection during handling and transport.

Advantages of stacking bags in food industry

Stacking bags offers advantages such as maximizing storage capacity, lowering labor expenses, and minimizing crop spoilage. Customizable automated palletizing machines can handle various bag sizes and weights, further enhancing operational efficiency. In summary, the practice of stacking bags plays a vital role in enhancing crop quality, reducing waste, and promoting sustainability in the food industry.

Stacking Crates in Food Industry

Efficient stacking of products in crates is essential for the food industry to ensure smooth storage and transportation of products from the farm to the processing plant and ultimately to the consumer. By using crate and palletizers, the industry can minimize waste, increase efficiency and contribute to its overall success and sustainability.

Proper sorting of produce by size and weight ensures that crates are filled optimally without exceeding their capacity or causing damage to vegetables. Crates are then carefully stacked on pallets using forklifts or other suitable equipment. Palletizers help to efficiently place the crates on the pallets, creating a stable load that can be easily transported and stored.

Palletizers enable the optimization of storage and transportation space

By stacking crates uniformly and securely on pallets, companies can maximize the use of available space and streamline logistics operations.

Food Products for Palletizing Applications

Grains

Rice

Corn

Sugar

Salt

Coffee and Cocoa

Cereals

Milk Powder

Bakery Materials & Flour

Verbruggen’s Palletizing USP’s

Based on our extensive experience in palletizing, Verbruggen palletizers offer the following advantages in stacking your bags, boxes or crates with products:

Videos of Palletizing Solutions in Food Industry

Discover Our Various Palletizers

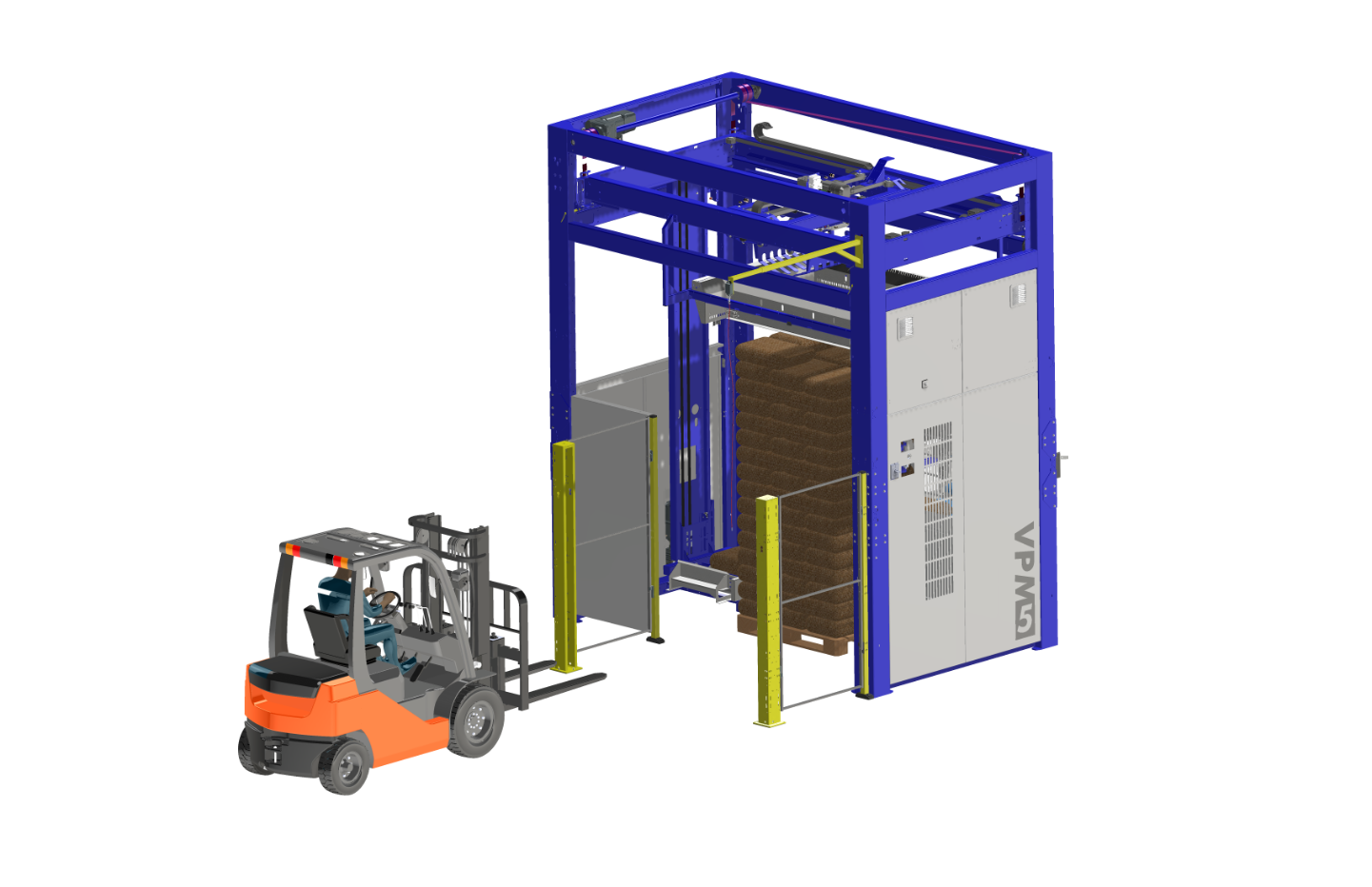

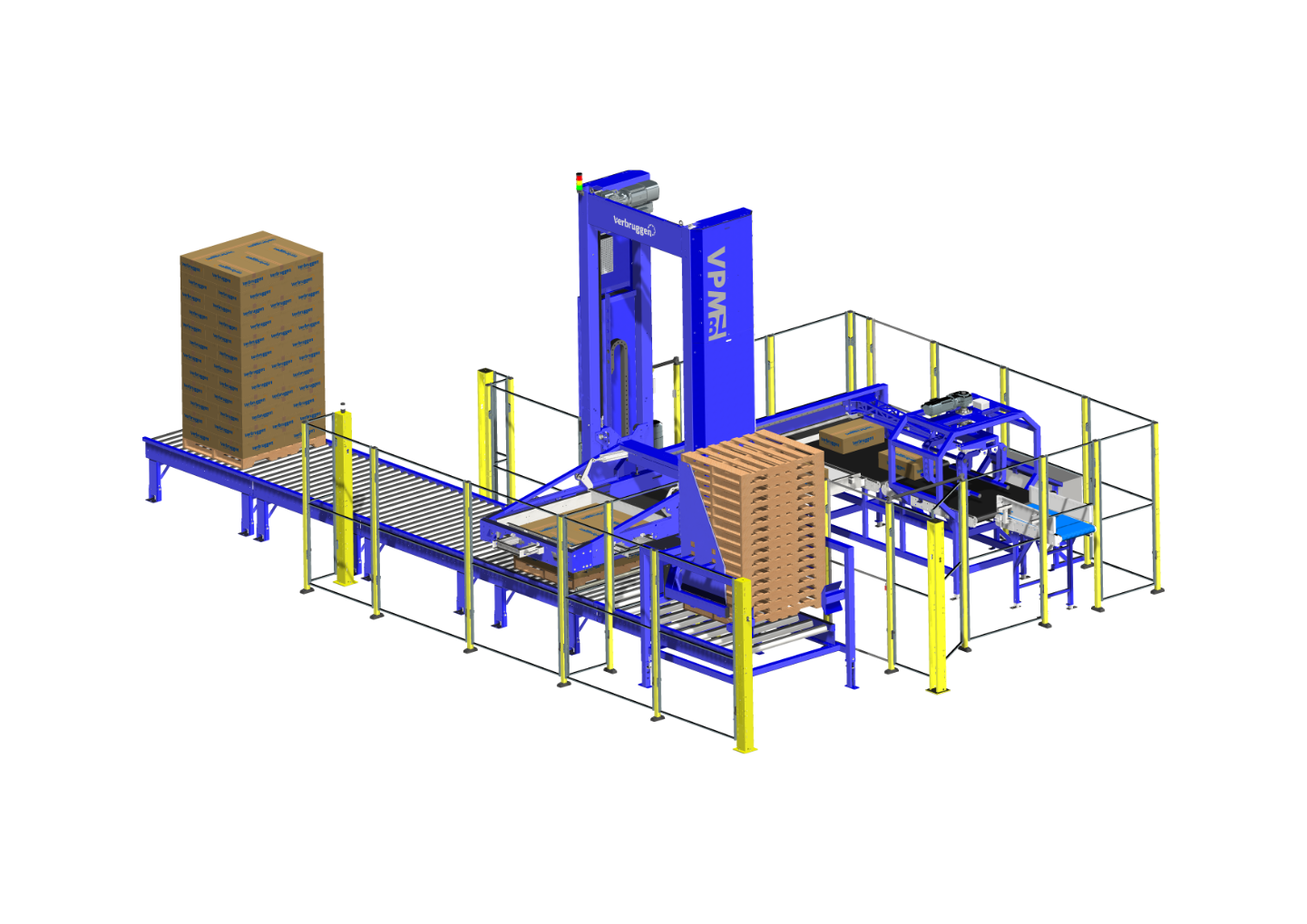

VPM-5

Handling bags

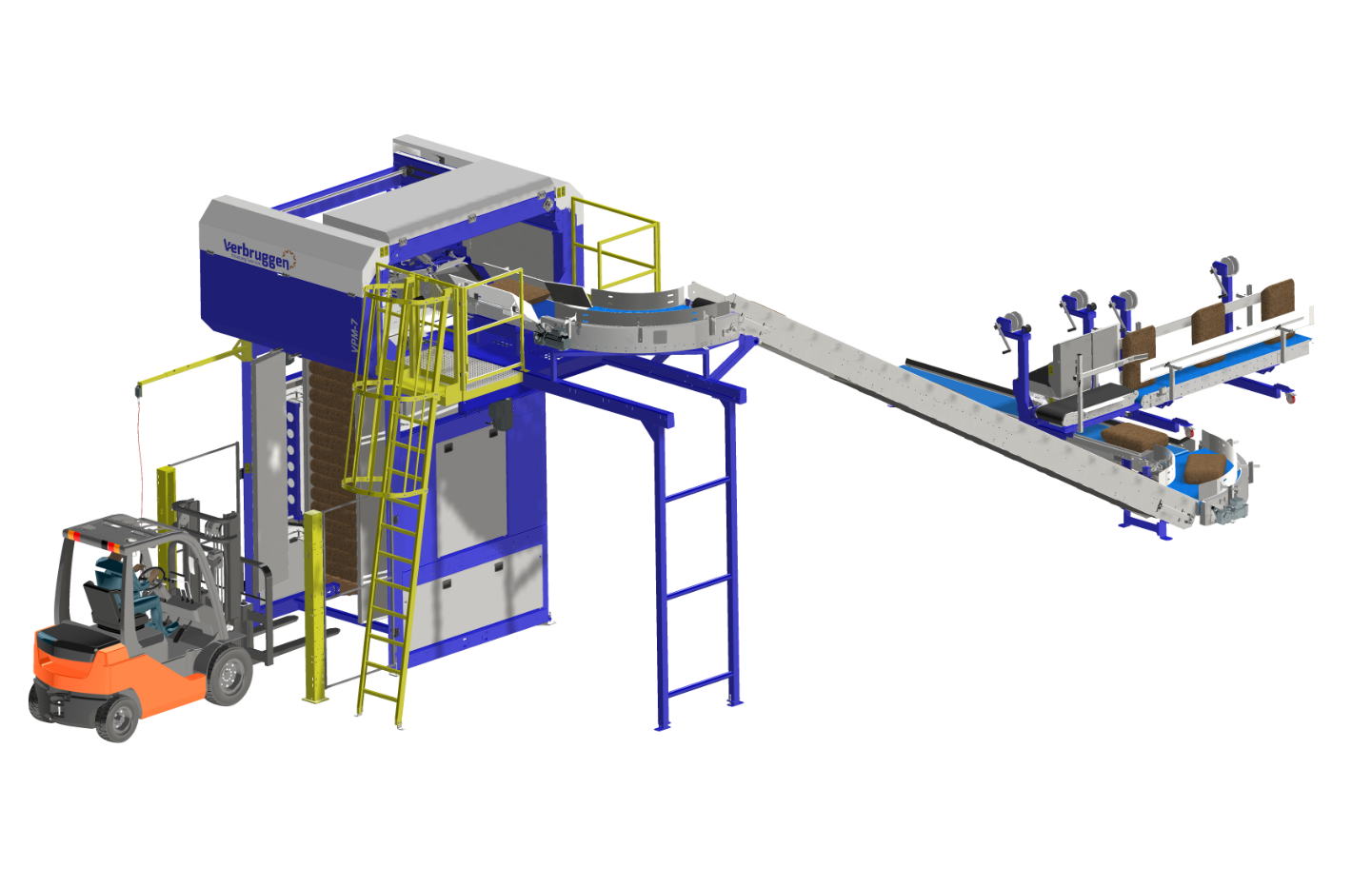

VPM-7

Handling bags and / or boxes

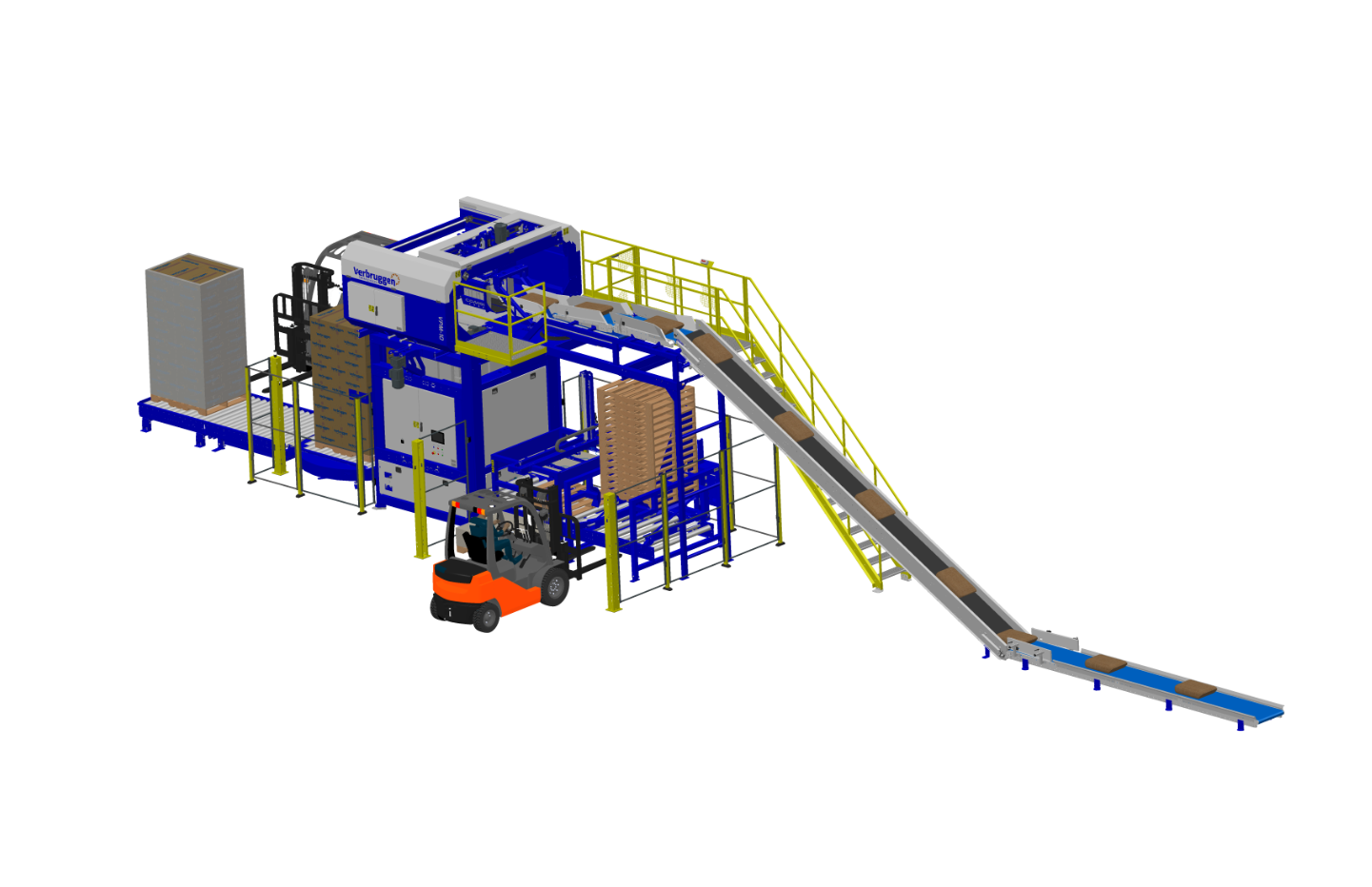

VPM-8

Handling bags and / or boxes

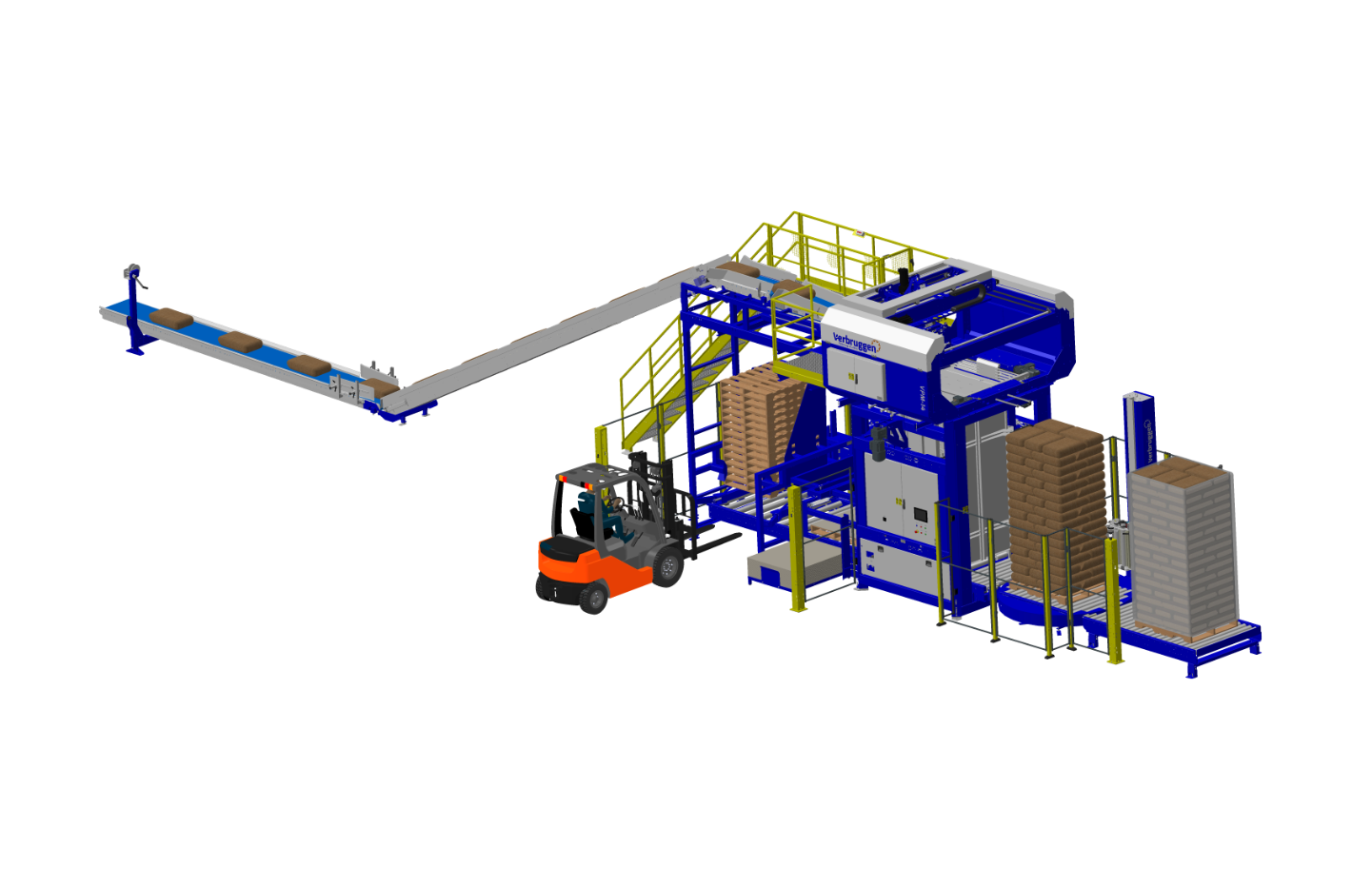

VPM-10

Handling bags and / or boxes

VPM-14

Handling bags and / or boxes

VPM-BL

Handling boxes / cartons / crates / wraps

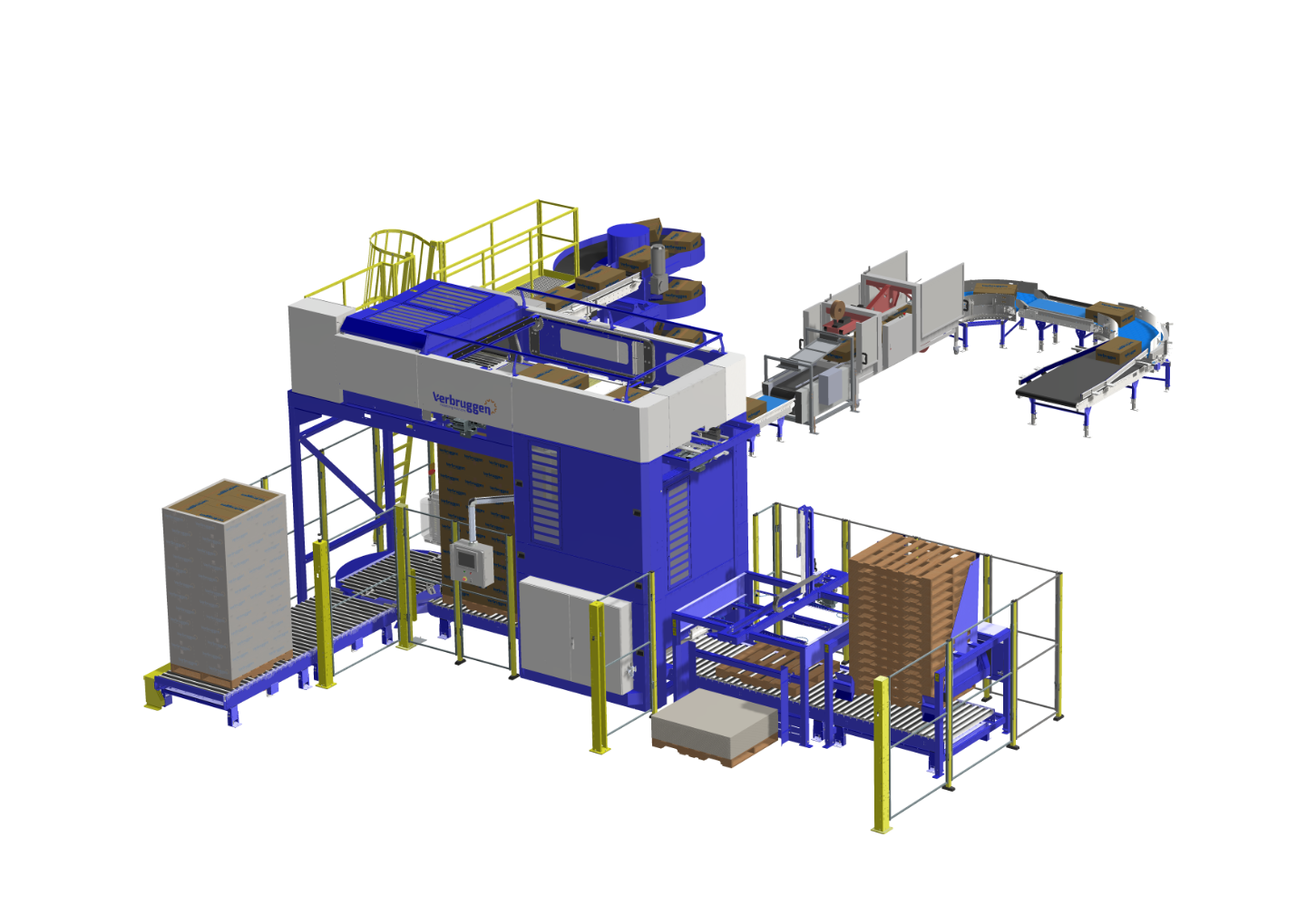

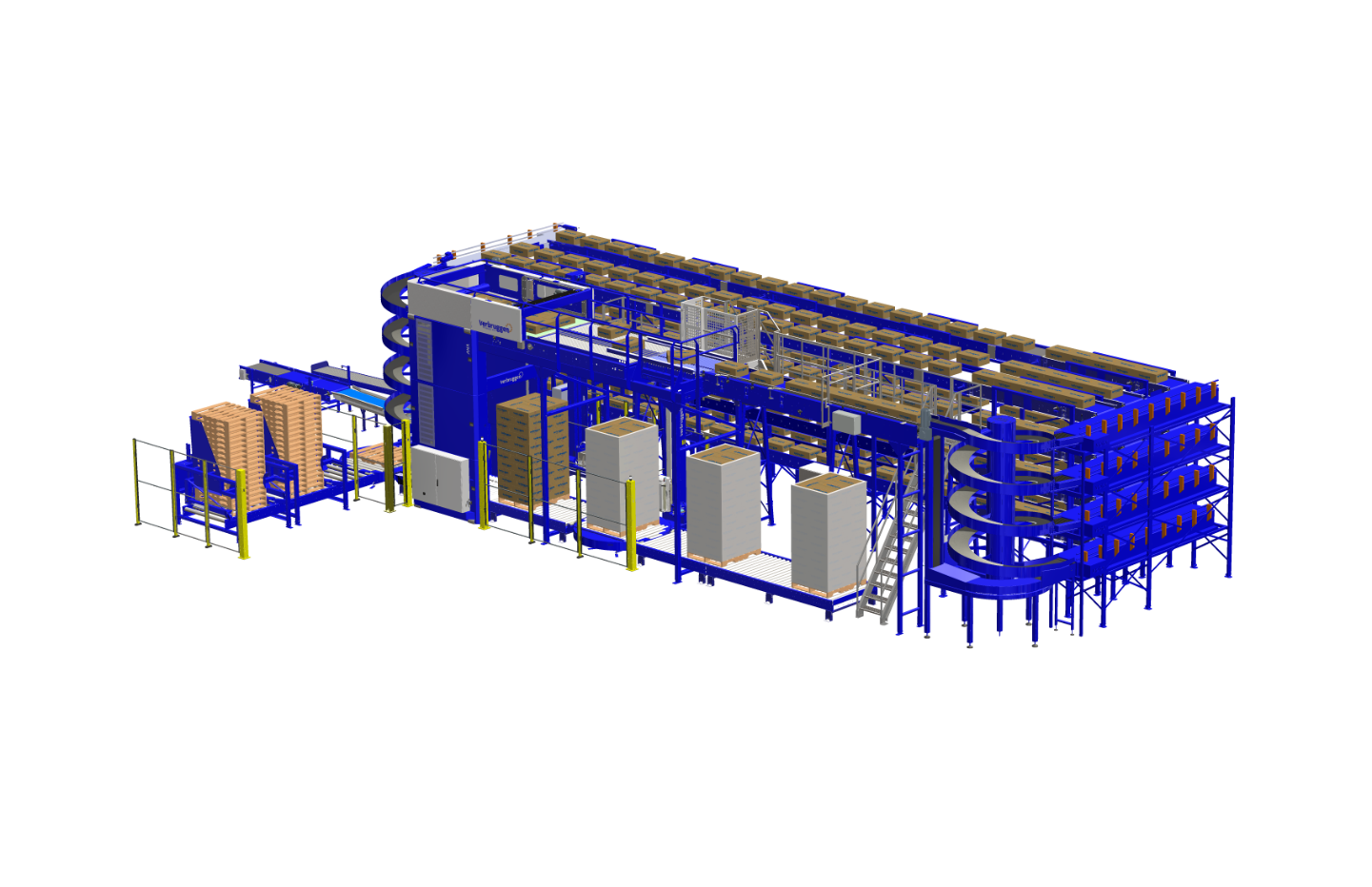

VPM-ACP

Handling boxes / cartons / crates / wraps

VPM-VHV

Handling boxes / cartons / crates / wraps

FAQ

What are food palletizing robots?

Food palletizing robots involve organizing products on pallets for storage or transportation. Palletizers are machines that automate this process, using robotics and other methods to accurately stack products of varying sizes and shapes onto pallets.

Palletizers optimize storage and transportation processes by efficiently stacking products on pallets. This leads to reduced storage space requirements and better utilization of transportation vehicles.

Palletizing process

Palletizing is the process of using a palletizer machine to stack and arrange products onto a pallet. It involves transporting the products to the palletizer and using a robotic arm or mechanism to stack them in a predetermined pattern. To secure the products, a wrapping machine may be utilized. Once fully loaded and wrapped, the pallet is ready for storage or transportation.

The exact steps may vary depending on the type of products, production needs, and level of automation. The objective is to efficiently and securely stack the products for effective transportation and storage.

What is food palletizing?

Food palletizing can offer several benefits for organizations in the food industry beyond the general advantages of increasing productivity and reducing labor costs. By optimizing the palletizing process, businesses can reduce food waste and improve food safety.

Proper palletizing can minimize the risk of product damage and contamination during transportation, ensuring that food products arrive at their destination in the same condition they were packaged in. Additionally, palletizing can help prevent cross-contamination between different food products, which is crucial in ensuring food safety and meeting regulatory standards.

Why Choose a Verbruggen Palletizer for Food Industry?

Gentle product handling

Verbruggen palletizers are particularly suitable for processing bags (of food) because of special features allowing round and irregular shape of the units to be stacked in a compact and tall format up to 2,5 meters.

Flexibility

Verbruggen’s own intelligent software enables the use of 20 possible stacking patterns, which makes it easy for customers to choose the best stacking patterns when palletizing different sizes of bags. It is also possible to combine bags and boxes or stack bags in boxes.

High speed stacking and accuracy

Verbruggen palletizers deliver high quality stacking in a high speed. Automated stacking of bags, crates or boxes from 10 to 40 bags per minute, and up to 120 boxes per minute

Local service availability

Besides our own branch offices in The Netherlands, USA, China and Bangladesh, we have an extended network of partners worldwide offering local service availability.

Good ROI; save labor costs and space

Choosing a Palletizing solution of Verbruggen will not only save labor costs and provide a better and more save working environment. It also saves space in storage and transport. Finally it also reduces product loss due to unstable and damaged stacks. Altogether a healthy investment, and we are more than happy to help calculate your ROI.