Discover the benefits of automated palletizing

Less product damage through careful handling

Using a palletizer can significantly reduce product damage during the handling and transportation process. Palletizers are designed to carefully and efficiently stack products onto pallets in a way that minimizes the risk of damage. By automating the palletizing process, products are carefully loaded and unloaded without being jostled or dropped, reducing the risk of scratches, dents, or other forms of damage.

In addition, palletizers can be programmed to stack products in a way that maximizes stability and minimizes the risk of shifting or toppling during transportation. This helps to prevent damage caused by products rubbing against each other or being crushed under their own weight

Higher and stable stacking

When it comes to palletizing products, one of the key benefits of using a palletizer is the ability to achieve higher and more stable stacking of pallets. This is especially important for companies that need to maximize their storage space and transport large quantities of products in a single shipment.

By using a palletizer, products can be stacked in a uniform and stable manner, which allows for higher stacking heights without compromising safety or stability. This means that companies can fit more products onto a single pallet, which can translate into significant cost savings and improved efficiency. By using precise and automated stacking techniques, companies can avoid overloading pallets or stacking them in a way that could lead to shifting or toppling during transit.

High speed stacking

High-speed stacking is a significant advantage of using a palletizer in modern manufacturing operations. By stacking products quickly and accurately onto a pallet, businesses can achieve optimal efficiency and productivity in their material handling processes. The ability to stack products at high speeds using a palletizer allows businesses to improve production throughput and reduce the need for manual labor. As a result, businesses can achieve significant cost savings and increased profitability over time.

Palletizing to more storage space

More storage space can allow businesses to take advantage of bulk purchasing opportunities, as they can store larger quantities of products without worrying about space limitations.

This can lead to cost savings and increased profitability over time.

Happy & Healthy employees

Investing in a palletizer for your organization can have a significant impact on the health and happiness of your employees. By automating the heavy lifting involved in palletizing products, employees no longer have to perform physically demanding tasks that can lead to injury and strain. This can promote a safer workplace and reduce the risk of work-related injuries, which can lead to increased job satisfaction and morale.

Automated palletizing has a strong ROI

A palletizer can provide a company with a strong ROI in several ways. By automating the palletizing process, companies can reduce the need for manual labor, which can result in cost savings related to labor costs. In addition, a palletizer can improve productivity by increasing the speed and accuracy of the palletizing process.

In combination with labor cost savings, a palletizer can also help reduce the risk of product damage during palletizing, which can result in additional cost savings related to product waste and rework.

By reducing product damage and waste, companies can also improve their overall product quality and customer satisfaction, which can lead to increased sales and revenue

Reduce stacking labor

By using a palletizer, businesses can greatly reduce the amount of manual labor required for stacking products. This is achieved through the high-speed stacking capabilities of the machine, which can stack products quickly and accurately onto a pallet without the need for human intervention.

Reducing stacking labor with a palletizer not only saves time and effort but also minimizes the risk of workplace injuries related to manual stacking. This can lead to a safer work environment and lower insurance costs for businesses.

With more storage space, businesses can store a greater volume of products on-site, reducing the need for off-site storage and increasing their inventory capacity. This can lead to a more streamlined supply chain and reduced transportation costs, as products can be stored and distributed more efficiently.

What is palletizing?

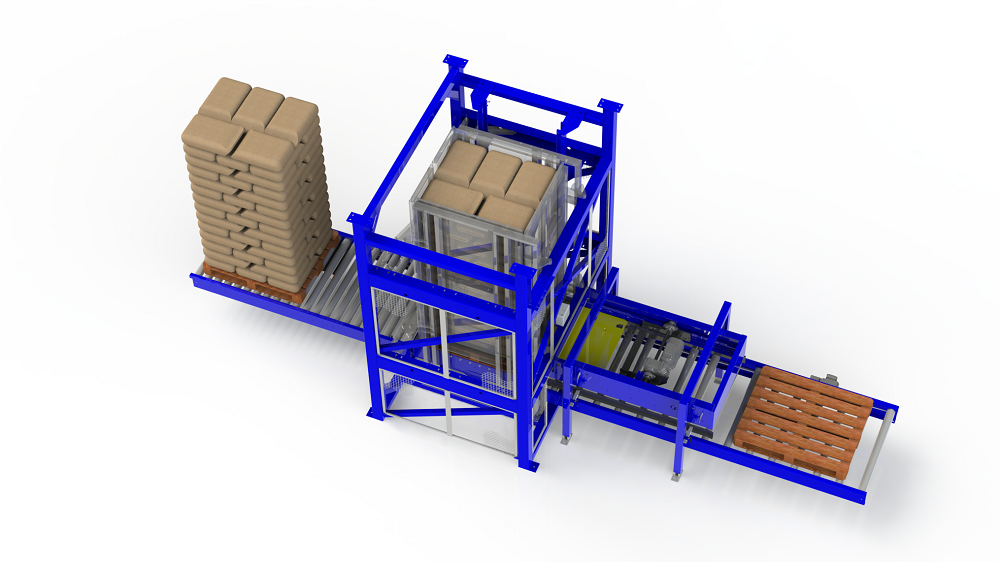

Palletizing is the process of stacking and arranging products onto pallets for storage or transportation. Palletizers are automated machines that are designed to handle this process efficiently and accurately.

These machines use various methods, including robotics, to move and arrange products onto pallets. Palletizers can handle a wide range of products, including boxes, bags, and containers of various sizes and shapes.

The use of palletizers can provide numerous benefits for companies, including increased productivity, improved efficiency, and reduced labor costs. By automating the palletizing process, companies can minimize errors and reduce the risk of product damage during the palletizing process.

In addition to these benefits, palletizers can also help companies optimize their storage and transportation processes. By stacking products onto pallets in a uniform and efficient manner, companies can reduce the space required for storage and improve the utilization of transport vehicles.

How to implement an efficient Palletizing process?

Implementing an efficient palletizing process is crucial for any organization that deals with storage and transportation of goods. A well-designed palletizing process can help minimize product damage, reduce labor costs, and improve overall efficiency.

To implement an efficient palletizing process, companies need to consider several factors, including the types of products being palletized, the required speed and accuracy of the process, and the available floor space.

One of the key steps in implementing an efficient palletizing process is selecting the right palletizing machine for the job. Factors to consider when choosing a palletizing machine include the machine’s capacity, versatility, and compatibility with the products being palletized.

Conditions of automated palletizing

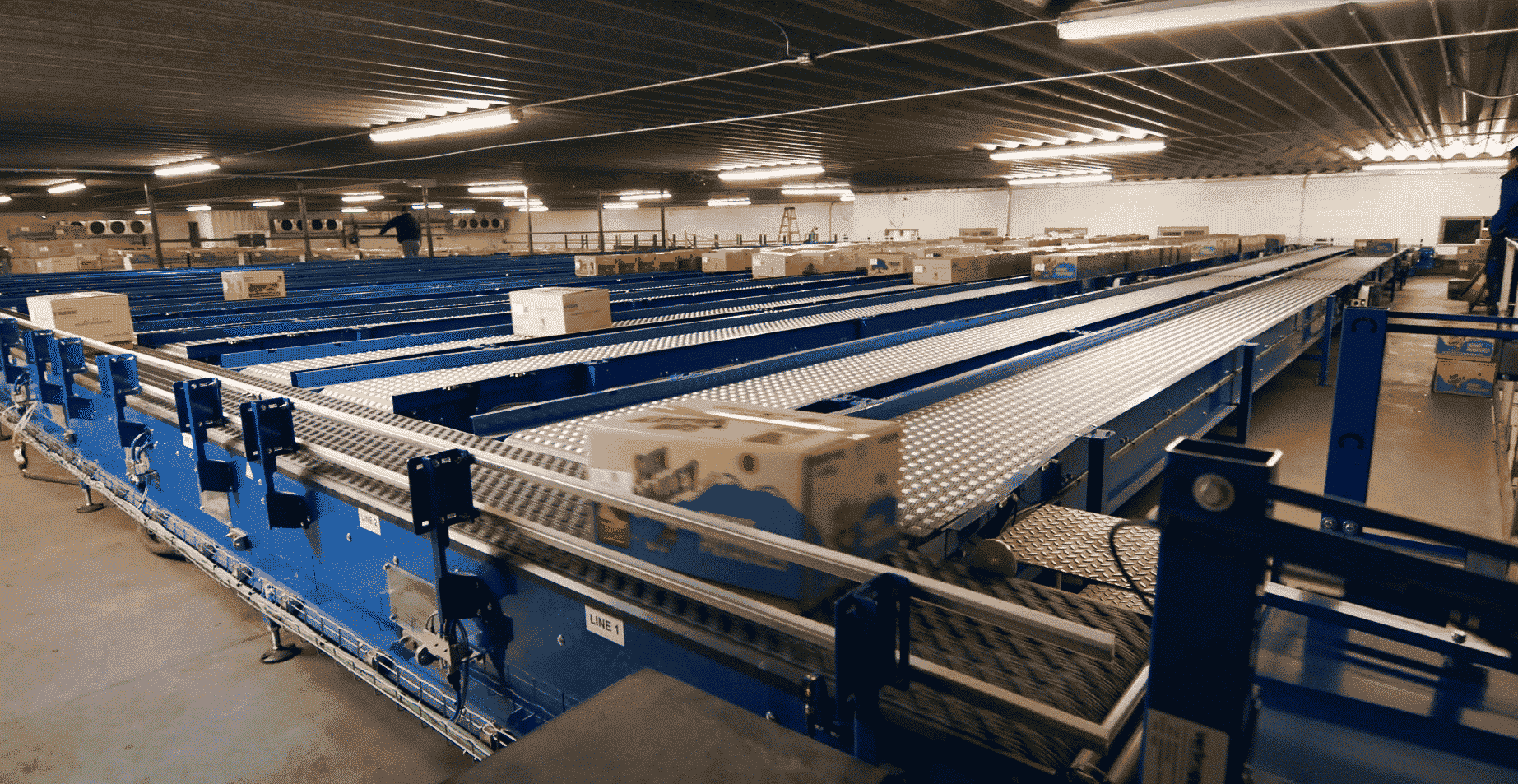

In addition to selecting the right palletizing machine, companies should also consider the layout of their palletizing area. The area should be designed to maximize efficiency and minimize the risk of product damage. This may involve creating designated loading areas and using conveyor systems to transport products to the palletizing machine.

To ensure the success of the palletizing process, companies should also provide appropriate training for employees who will be operating the palletizing machine. This training should cover machine operation, troubleshooting, and maintenance.

Overall, implementing an efficient palletizing process requires careful planning and consideration of several factors. With the right palletizing machine, layout, and employee training, companies can achieve significant improvements in productivity, efficiency, and cost savings

Stacking products

For businesses that engage in product stacking, finding the right palletizing solution can be critical to their success. Efficient palletizing not only ensures the safe transport of goods, but also saves time and money in the packing process.

Stacking boxes

Stacking boxes onto pallets is a common task in many industries, from manufacturing and warehousing to logistics and distribution. A palletizing process involves arranging boxes in a specific pattern on a pallet so that they can be transported safely and efficiently.

Efficient and effective box stacking is crucial for maximizing storage capacity and ensuring the safe and timely delivery of goods. Properly stacked boxes can also reduce the risk of damage or loss during transportation

Palletizers provide a fast and efficient way to stack boxes onto pallets in a uniform and stable manner. With a palletizer, businesses can significantly increase their production output and reduce the risk of worker injuries caused by manual box stacking.

Stacking bags

Stacking bags in a palletizing process involves arranging bags of various sizes and weights onto pallets in a specific pattern to maximize storage space and facilitate transportation. The process requires precision and careful planning to ensure that the bags are stacked safely and securely.

There are various factors to consider when stacking bags, such as the weight and size of each bag, the stability of the stack, and the type of palletizing equipment used. Some businesses may use automated palletizing machines, while others may rely on manual labor.

Palletizing solutions by industry

Palletizing in Agriculture

Palletizing solutions for the agriculture industry often involve the handling and packaging of crops such as grains, fruits, and vegetables.

Automated palletizing machines can handle different packaging types and sizes, including bags and totes.

Palletizing in Food

In the food industry, palletizing solutions must meet strict food safety standards. Automated palletizing machines with washdown capabilities are available.

Palletizing solutions for the food industry can also handle various packaging types and sizes, including trays, cases, and boxes.

Pet Food palletizing

Palletizing solutions for the pet food industry must be capable of handling various types of packaging, including bags, boxes, and pouches.

Palletizing solutions for the pet food industry can also be customized to handle specific bag sizes and weights.

Non-food solutions

Palletizing solutions for the non-food industry must handle various types of packaging. Automated palletizing machines can be customized to handle specific product dimensions and configurations. Palletizing solutions for the non-food industry can also handle high-volume production runs.

Discover several Palletizer machines

Are you looking for a solution to stack your bag, boxes and crates quickly, efficiently, and perfectly on pallets or sheets? Do you want to reduce labor costs and downtime, while maximizing loading space? Discover our palletizer machine as a perfect solution for your automated palletizing.

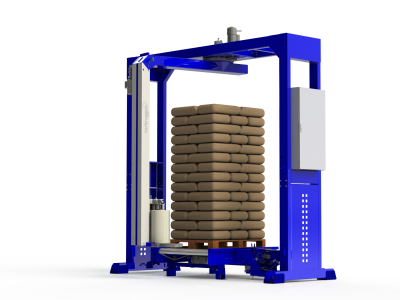

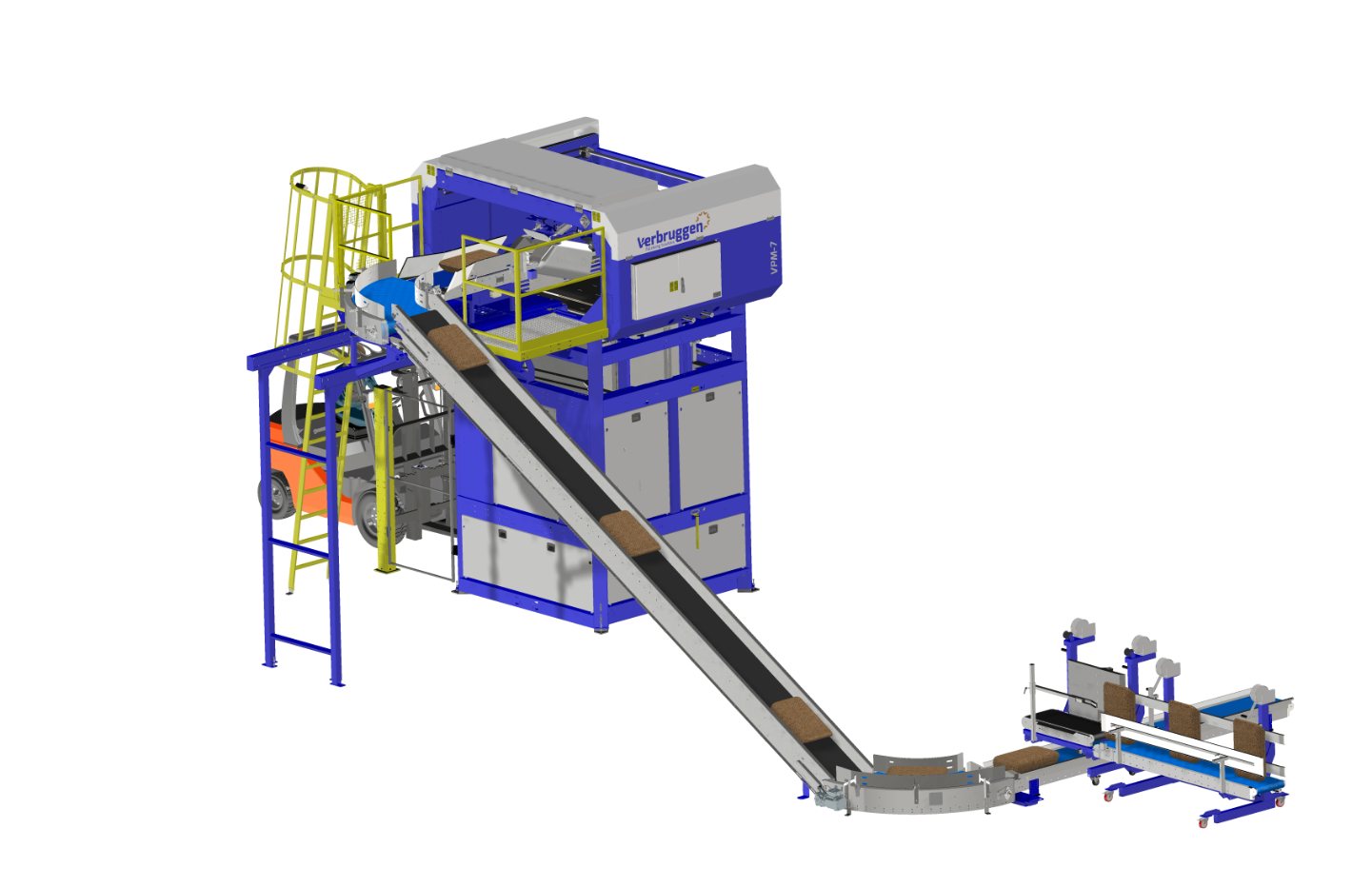

Verbruggen offers a diverse range of palletizer machines designed to meet your specific needs. We provide bag palletizers for handling bags of various sizes and materials, box palletizers for accommodating a variety of box sizes and weights, and wrapping machines for securely wrapping your pallets.

Our bag palletizers are built to handle bags of all sizes and materials with ease, while our box palletizers can efficiently handle a wide range of box sizes and weights. Our wrapping machines are designed to quickly and effectively wrap your pallets, ensuring their safety during transport.

Customized solutions based on your situation

In order to showcase the diversity of our projects, we would like to provide you with a few examples of our unique machine concepts. If you have a specific request, our engineers are always available to develop a customized solution for your situation, even for very tough-stackable products.

If you need to stack different sizes of products without a storage bunker, our smart installation can process three different sizes of onions simultaneously, integrating palletizers, weighing machines, and evenflow bins with product conveyors. Lastly, if your product is vulnerable to damage during transport, our indoor palletizing solution ensures tight stack tolerances, providing protection from all sides on the pallet.

Take a look at our range of customized solutions (below), including mobile palletizing, stacking nested crates, stacking different sizes, and stacking inside pallet measurements.

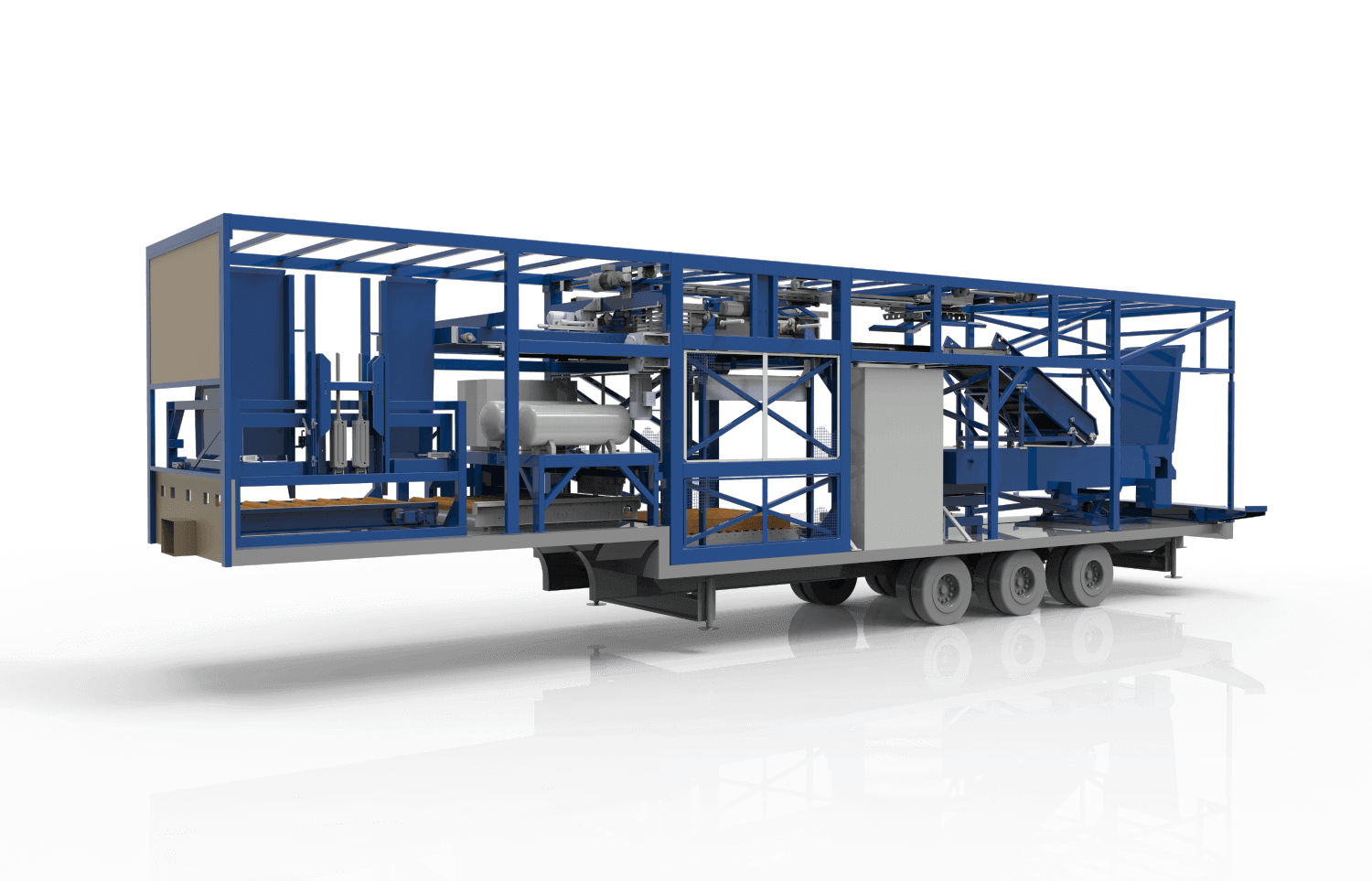

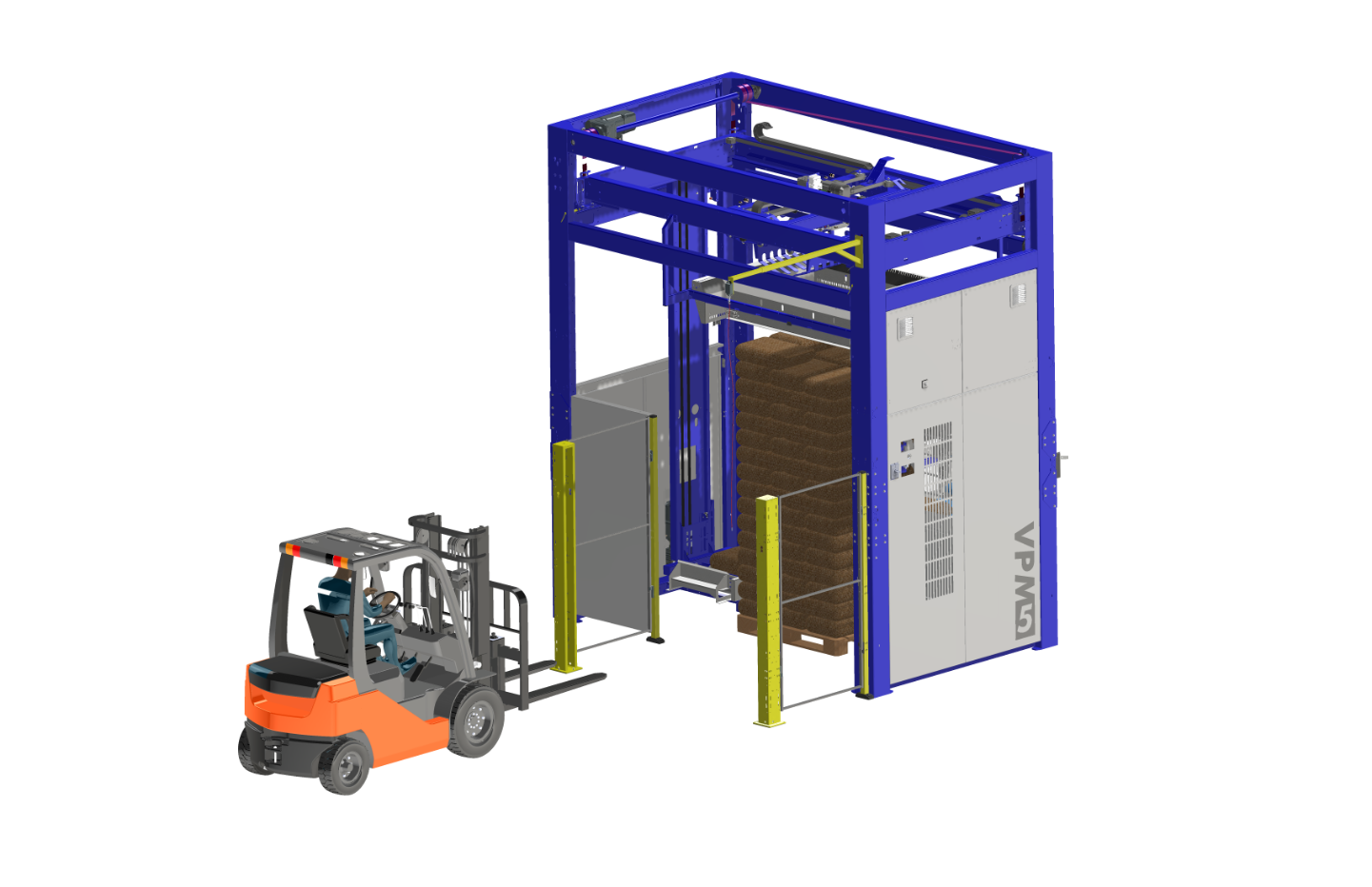

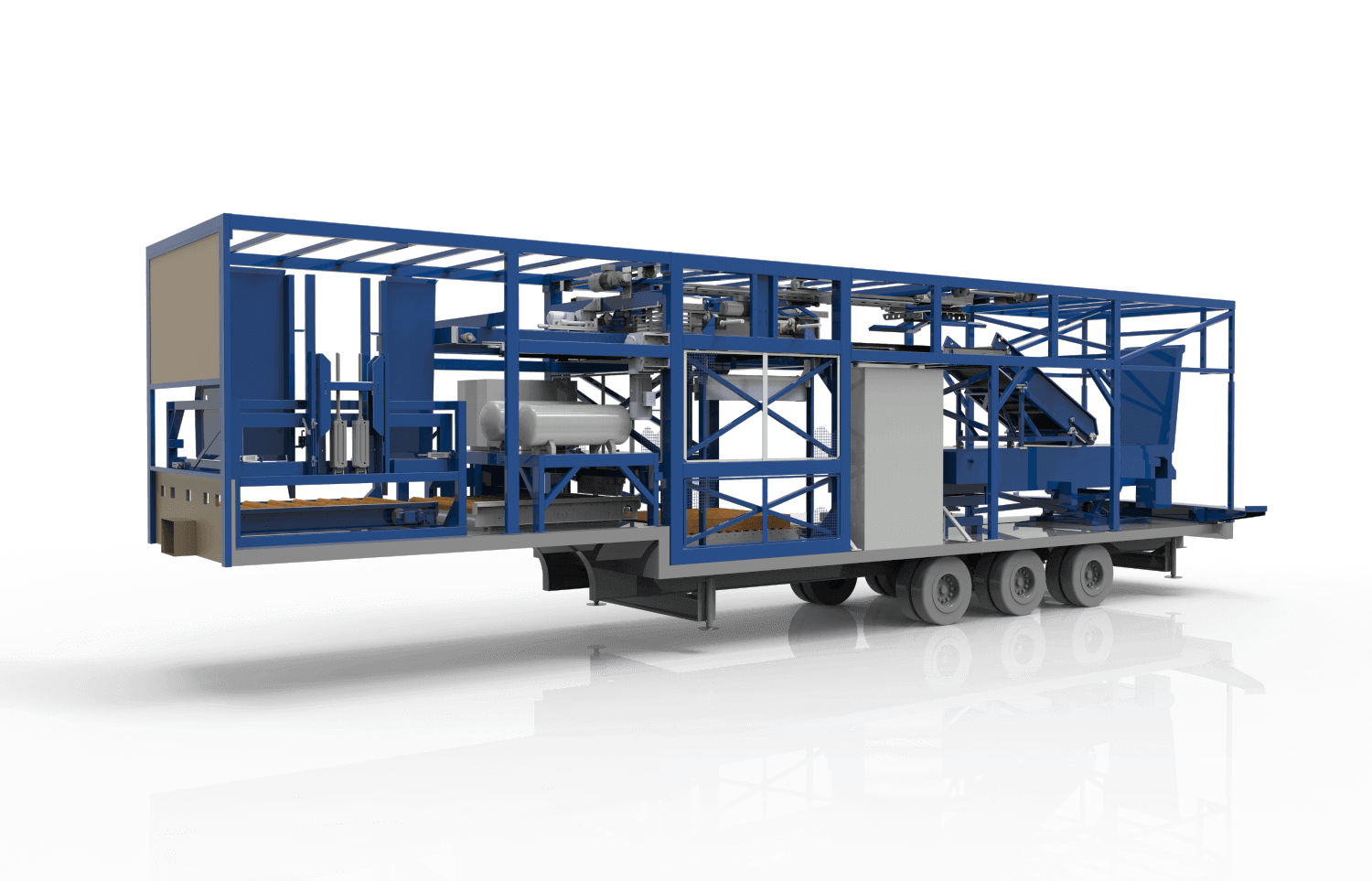

Mobile Palletizing

To be able to palletize on different locations with one machine, Verbruggen developed the VPM-Mobile. This machine is often used by bulking goods of storage and handling companies.

Unique is the easy transport of the machine by truck.

Our mobile palletizing machine, the VPM-Mobile, is ideal for palletizing goods at different locations with ease of transportation by truck.

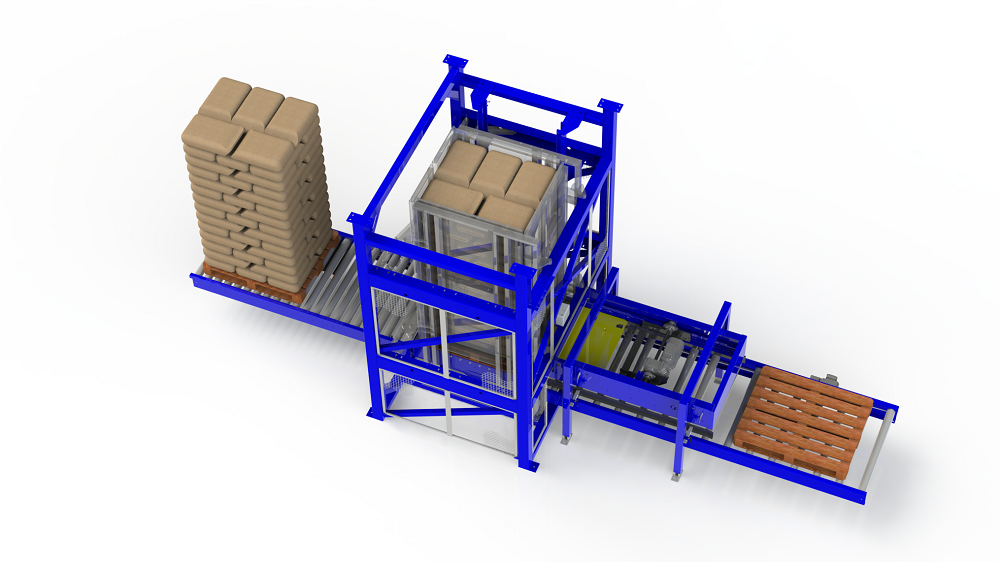

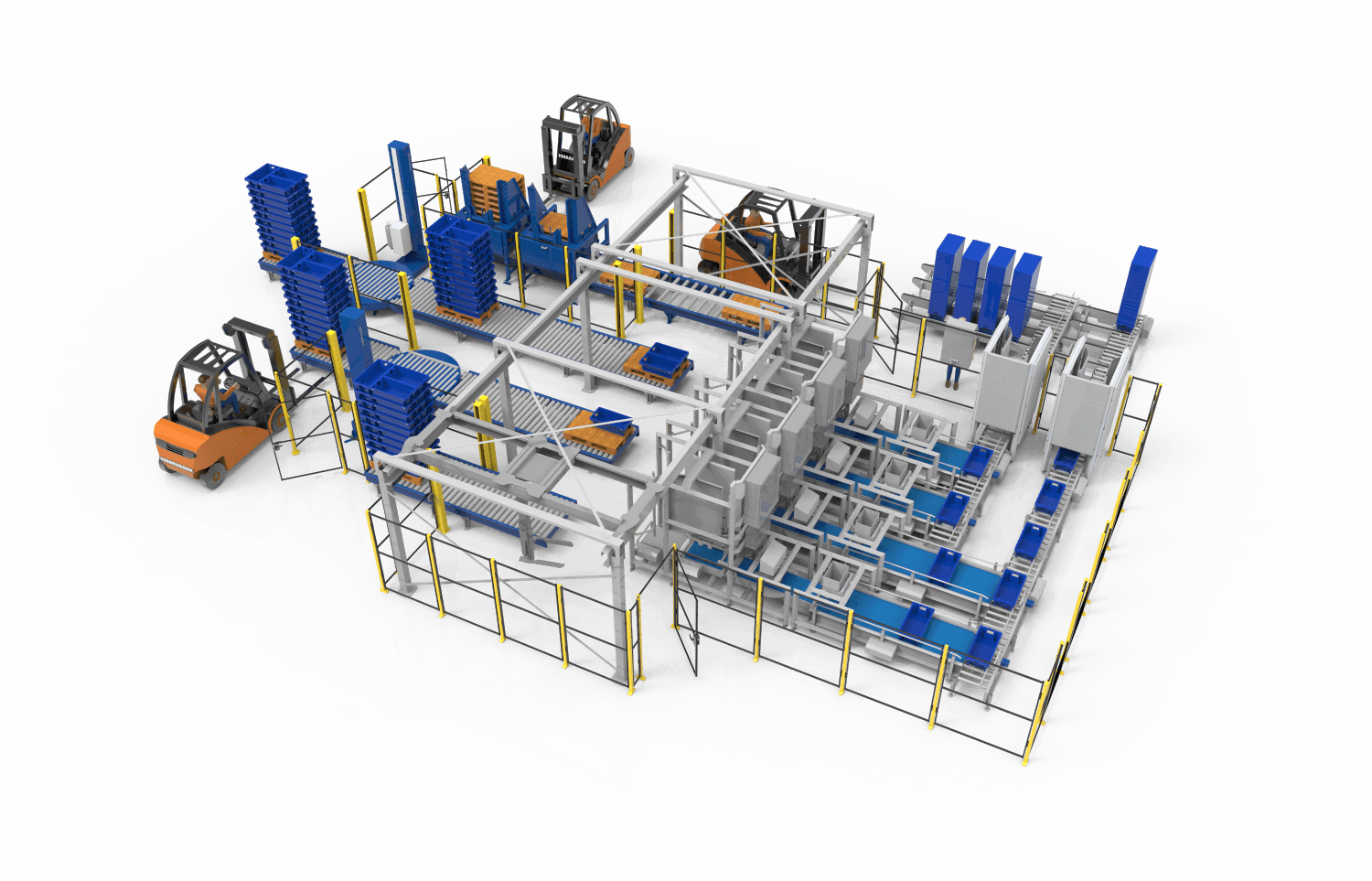

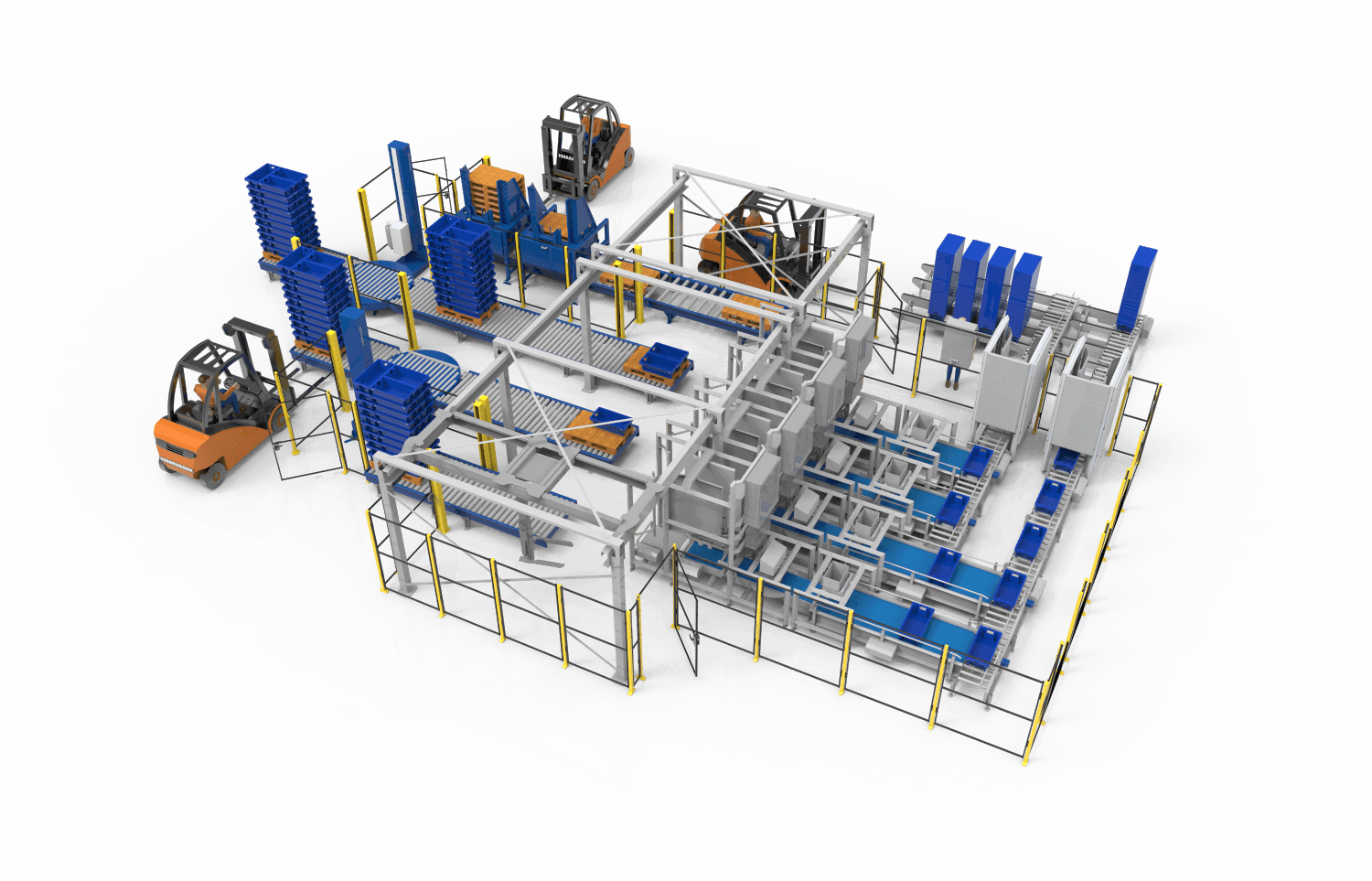

Stacking Nested Crates

Do you need to stack or unstack nested crates on high-speed? The VPM-CS is especially developed for processing products in stackable crates. The crates are supplied automatically and after being filled stacked stably on pallets.

The VPM-CS is designed to stack or unstack nested crates at high speed, making it a great option for fully automated processing of products in stackable crates.

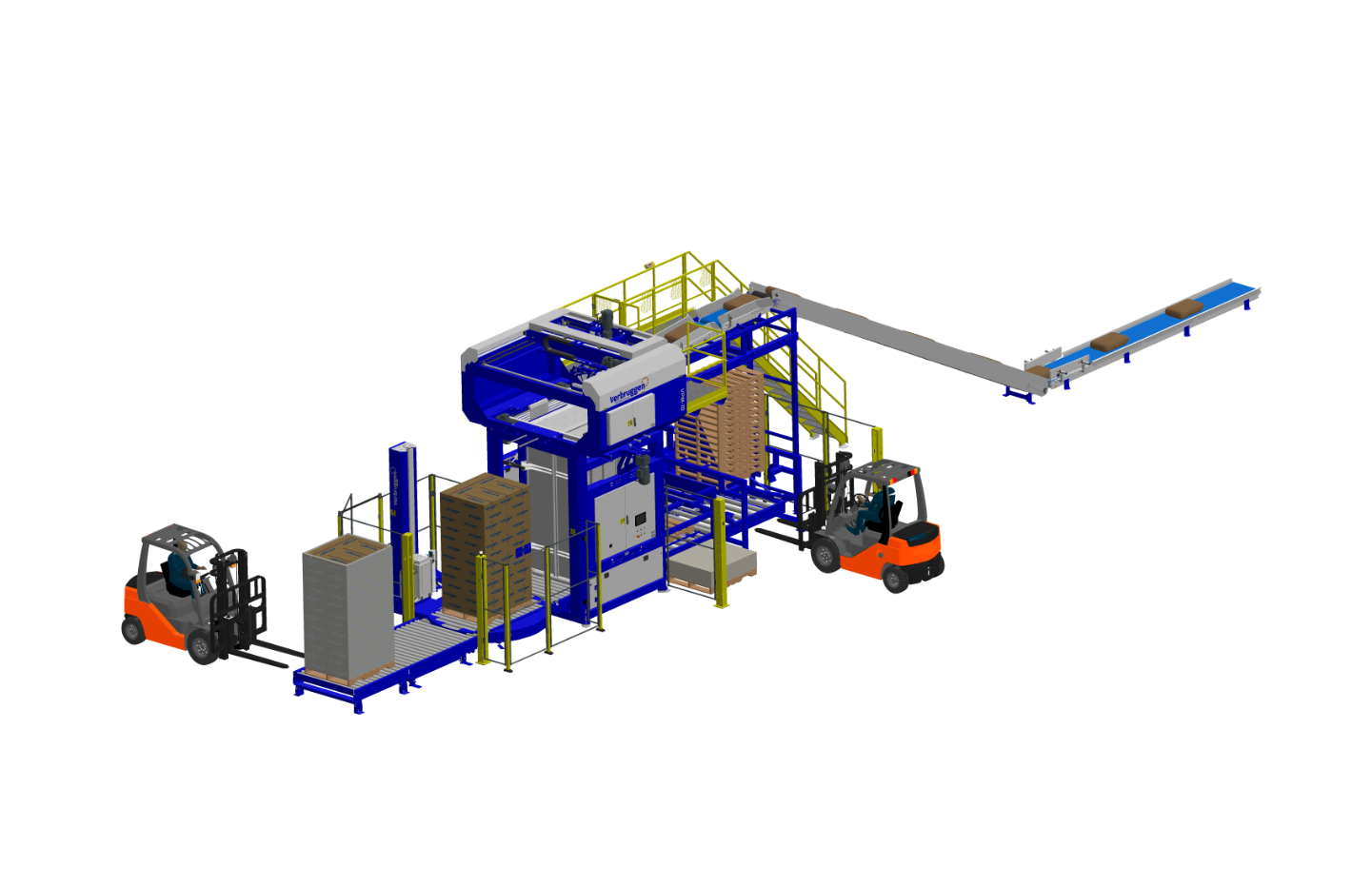

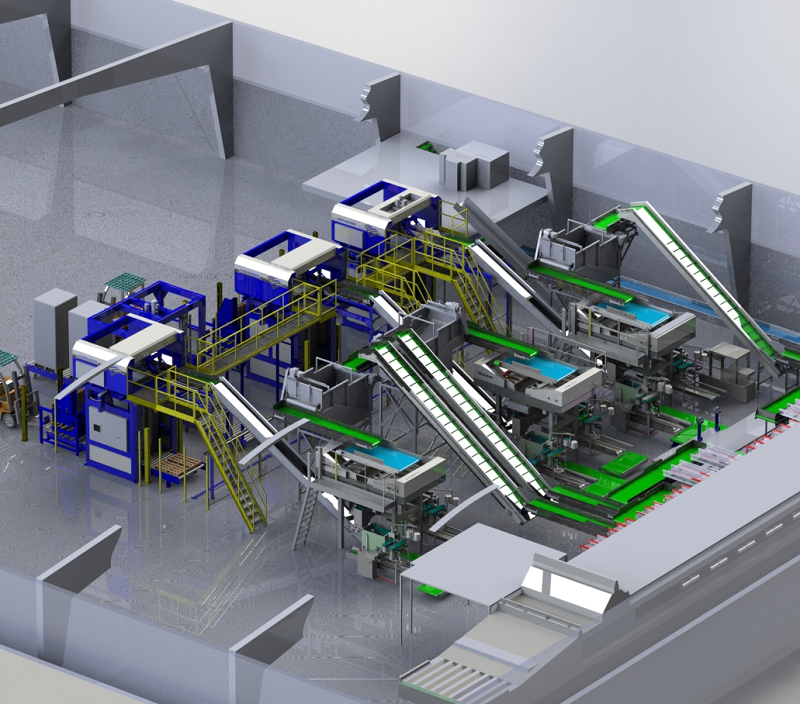

Stacking Different Sizes of Onions at Once

Stacking different sizes of onions without a storage bunker?

With this smart installation three different sizes are processed simultaneously. Three palletizers, three weighing machines and three evenflow bins and product conveyors are completely integrated in the existing production line.

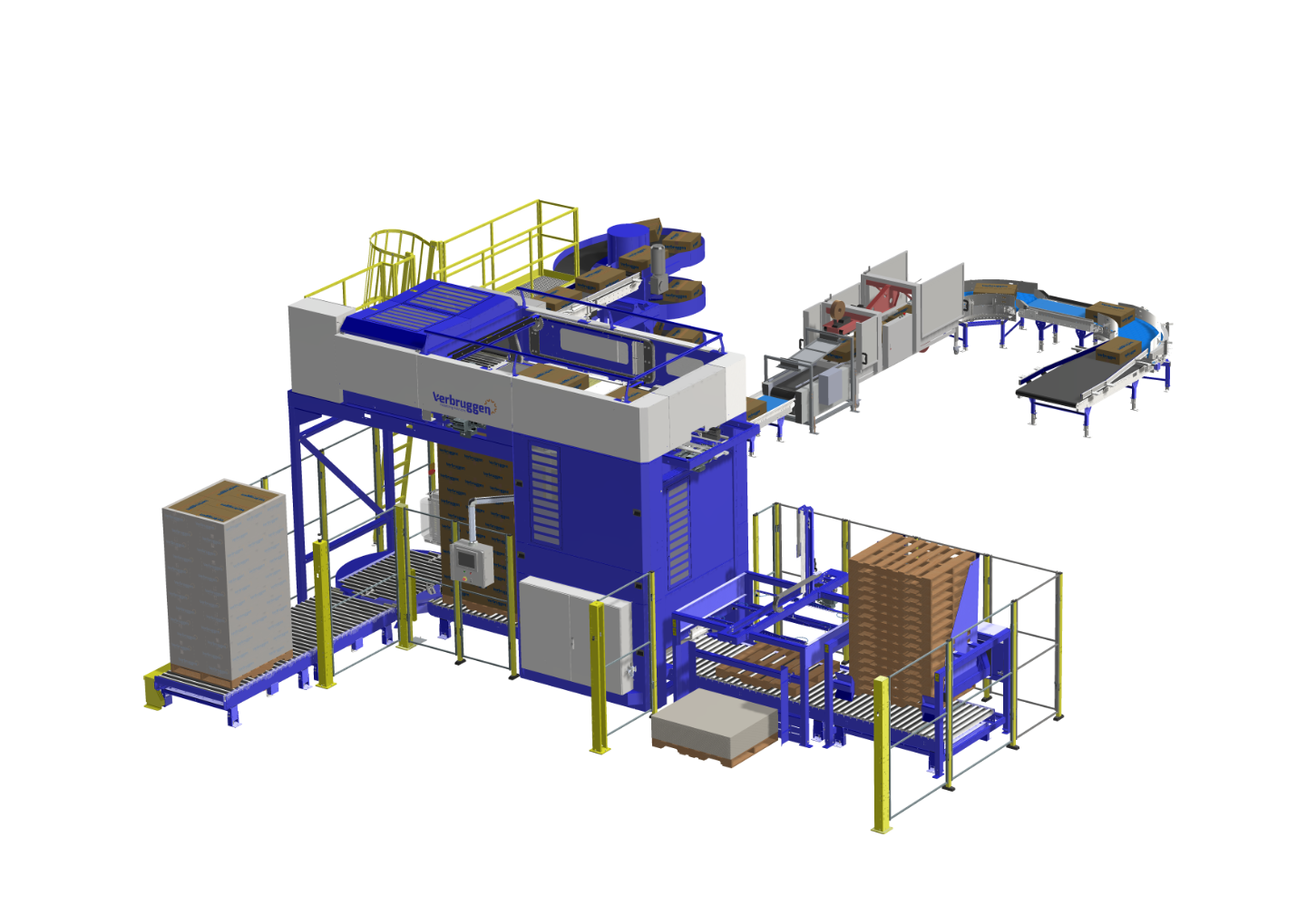

Stacking Inside Pallet Measurements

Is your product vulnerable for damage during transport?

Stack your product with our special indoor palletizing solution providing tight stack tolerances to be achieved prior to placement on a pallet resulting with protection of product from all sides on the pallet.