Handling bags / boxes / cartons / crates / wraps

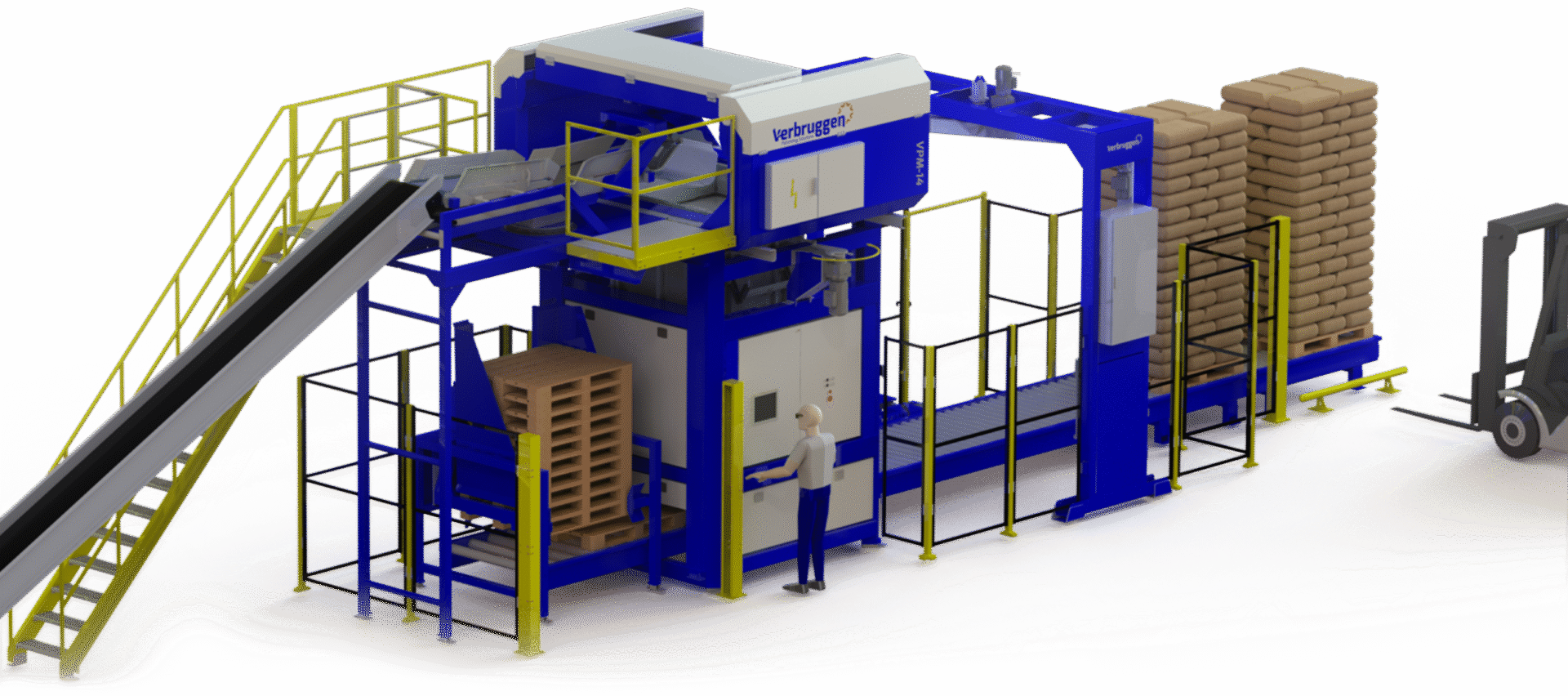

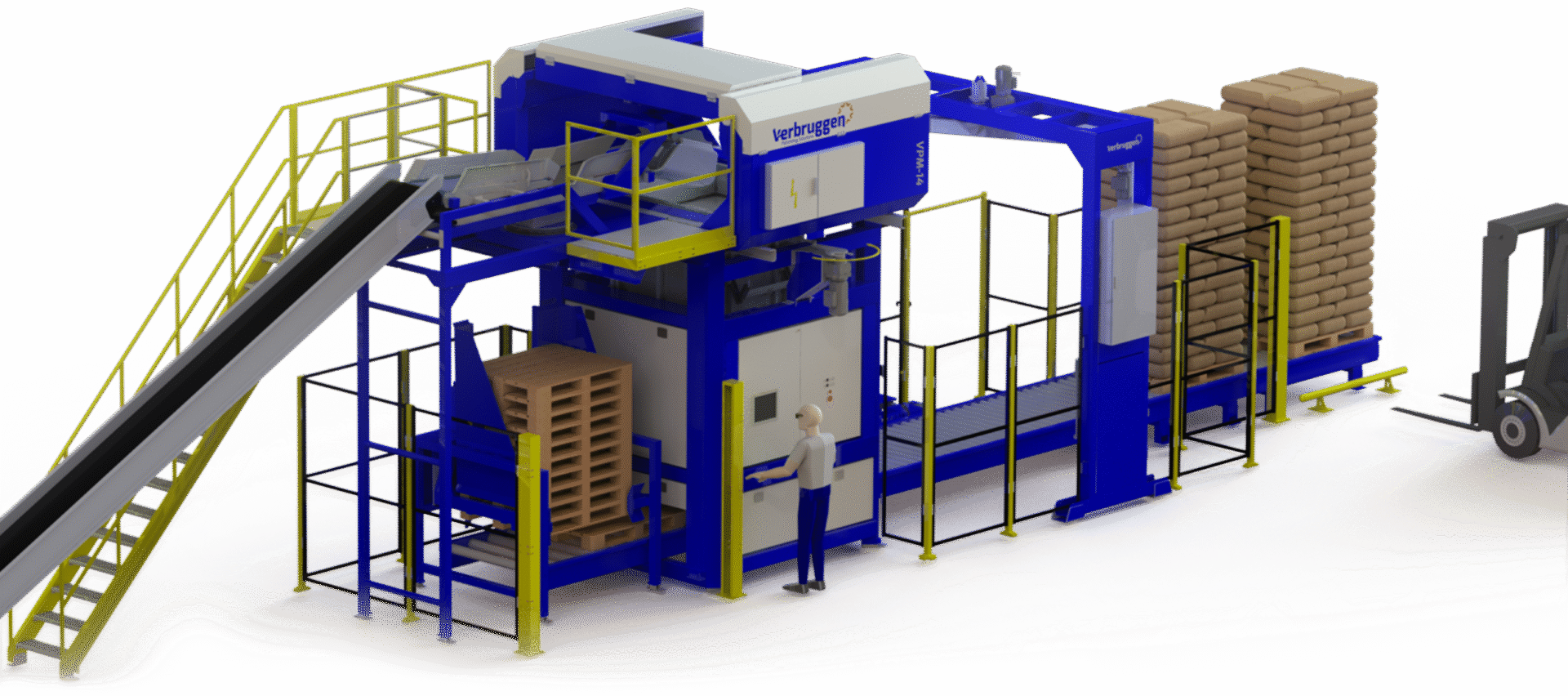

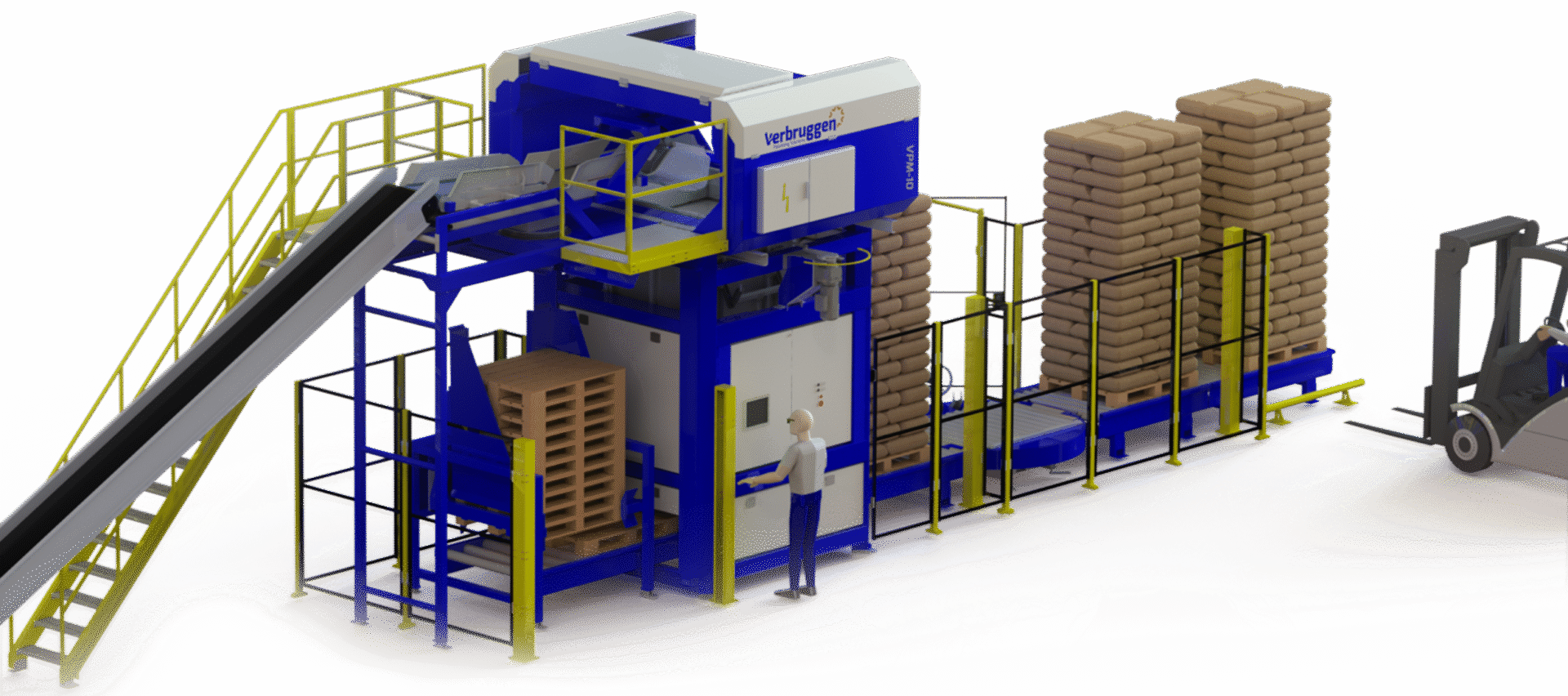

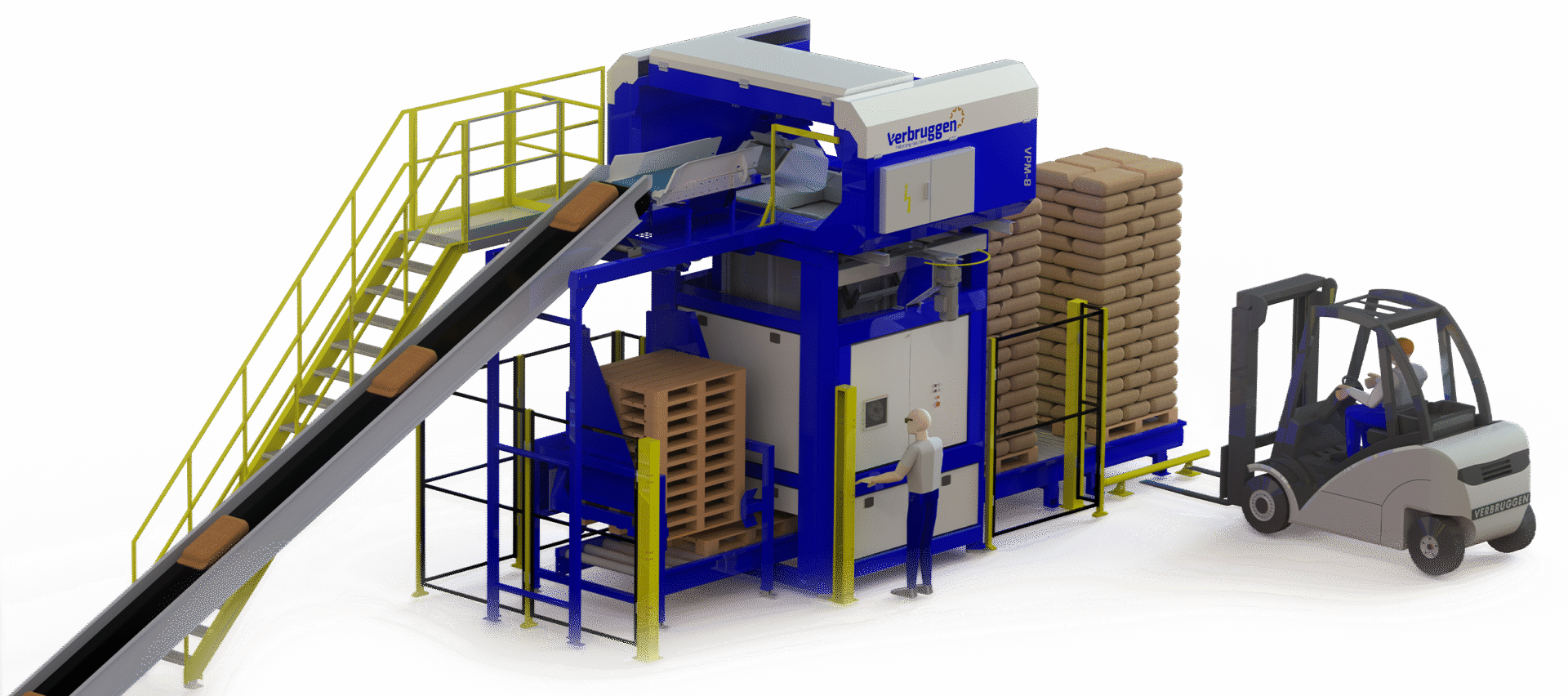

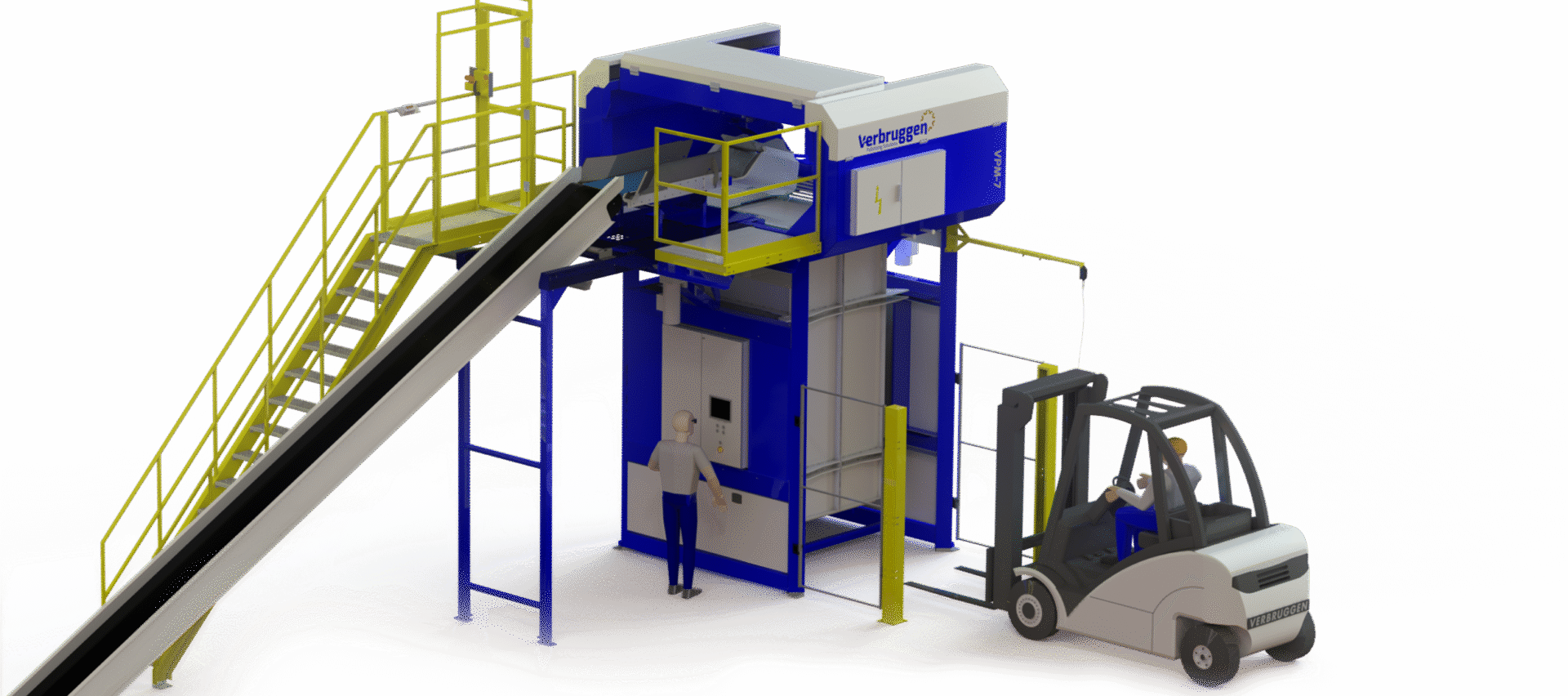

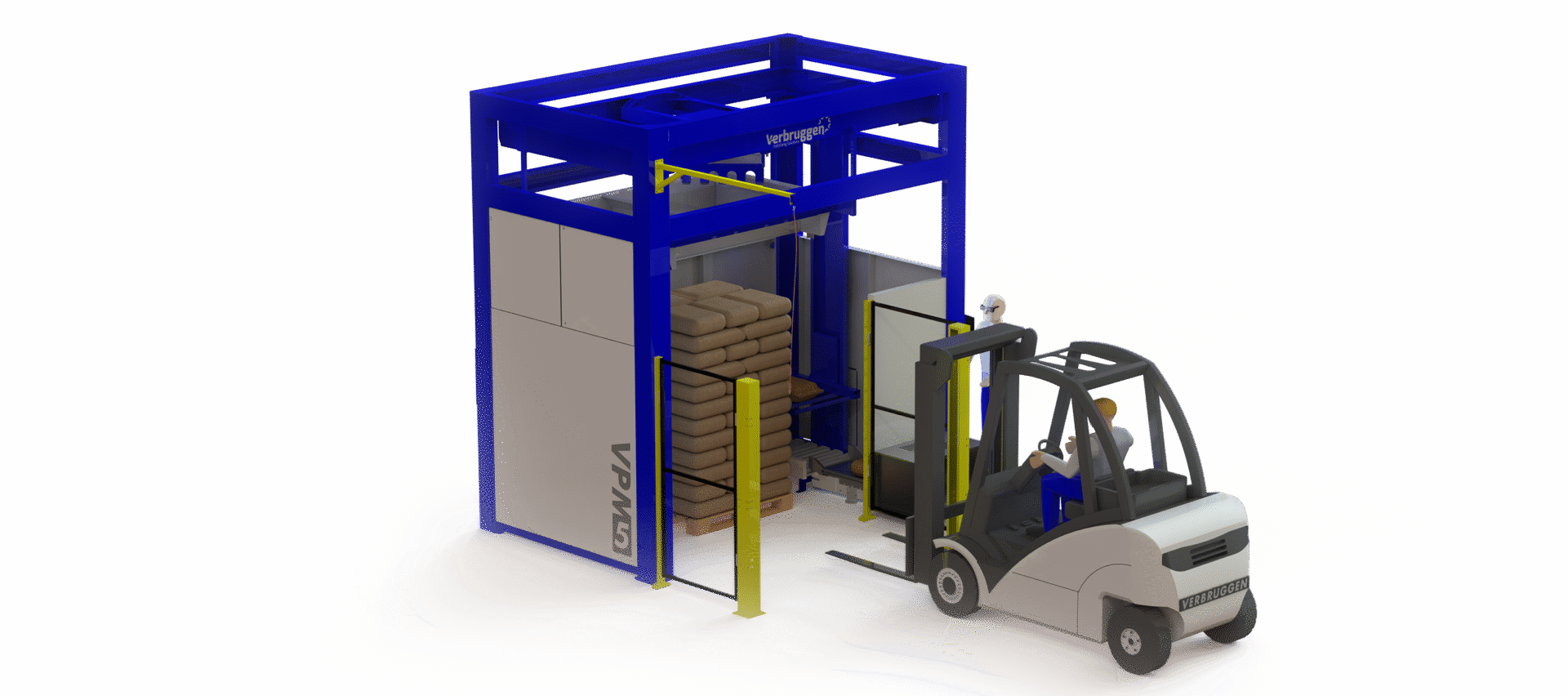

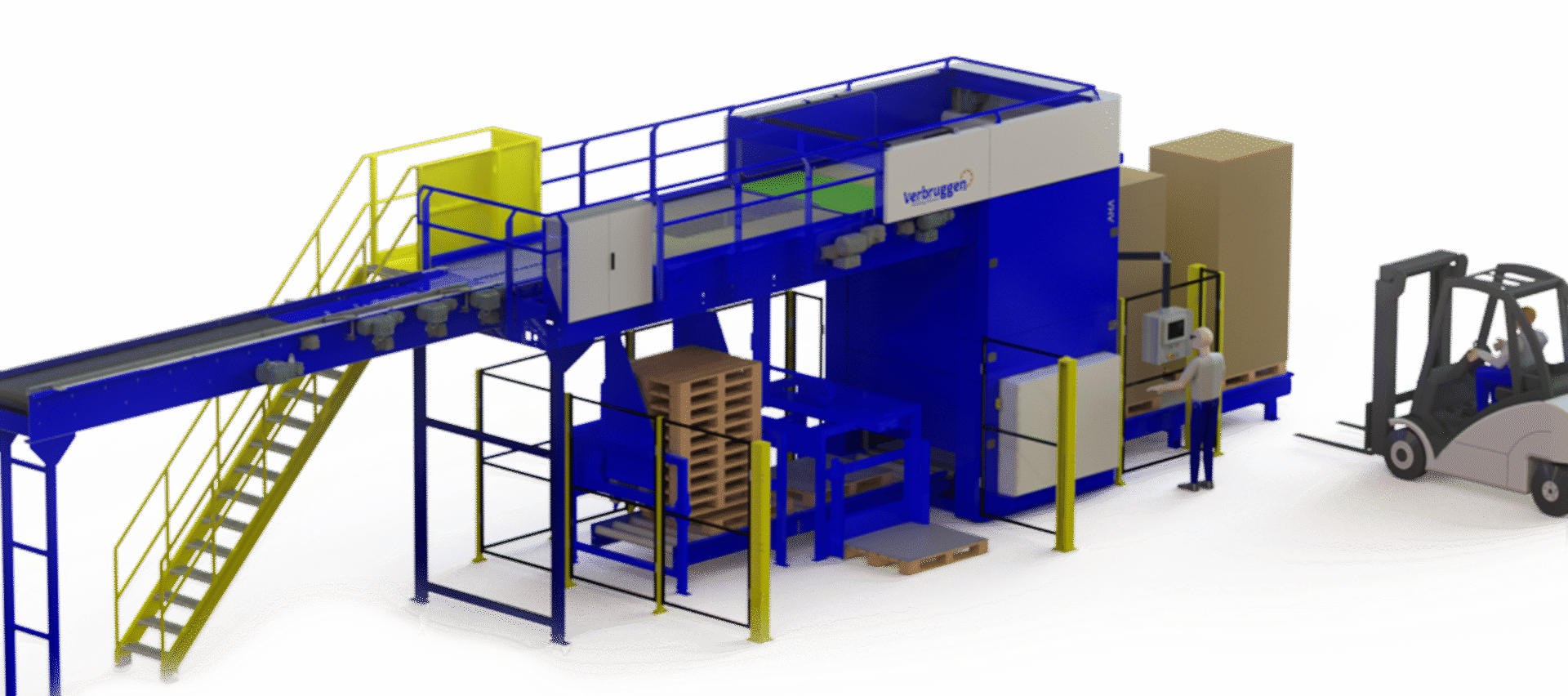

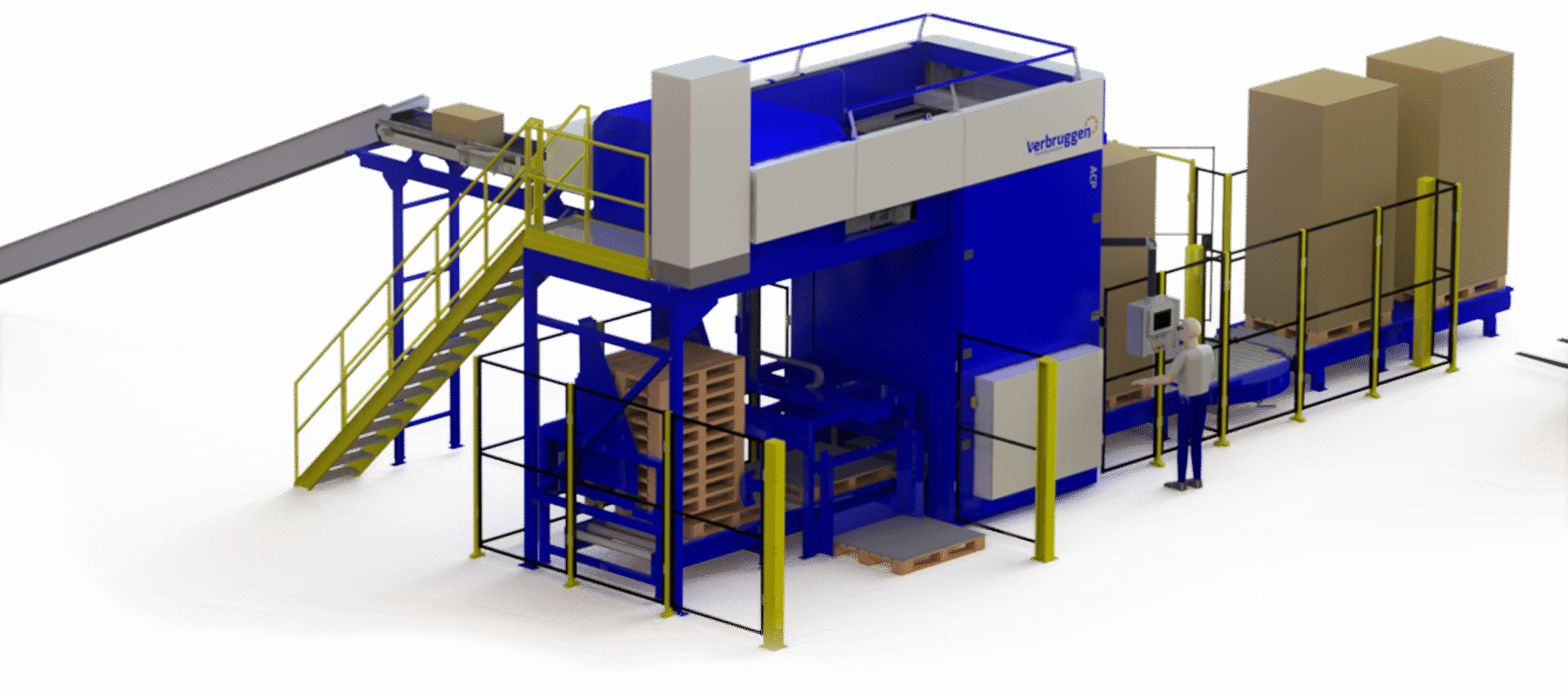

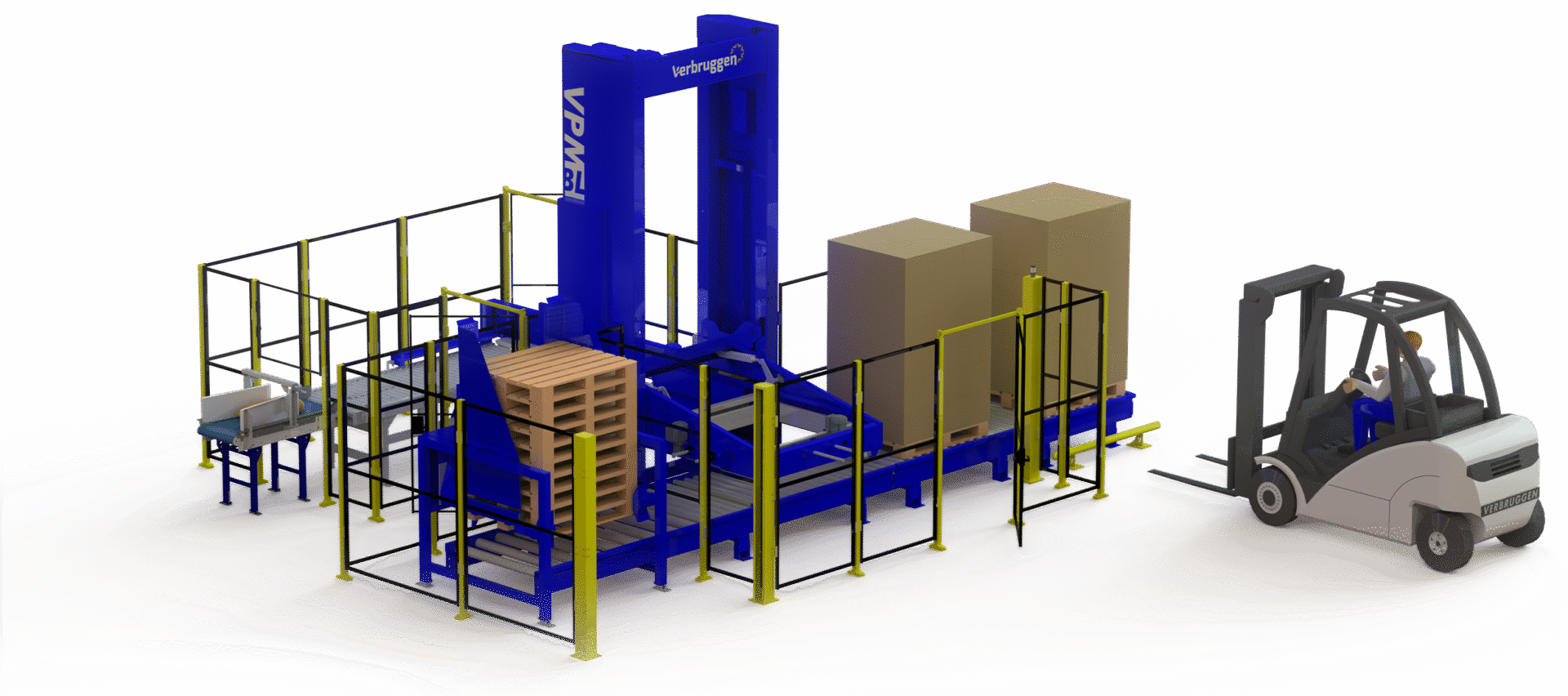

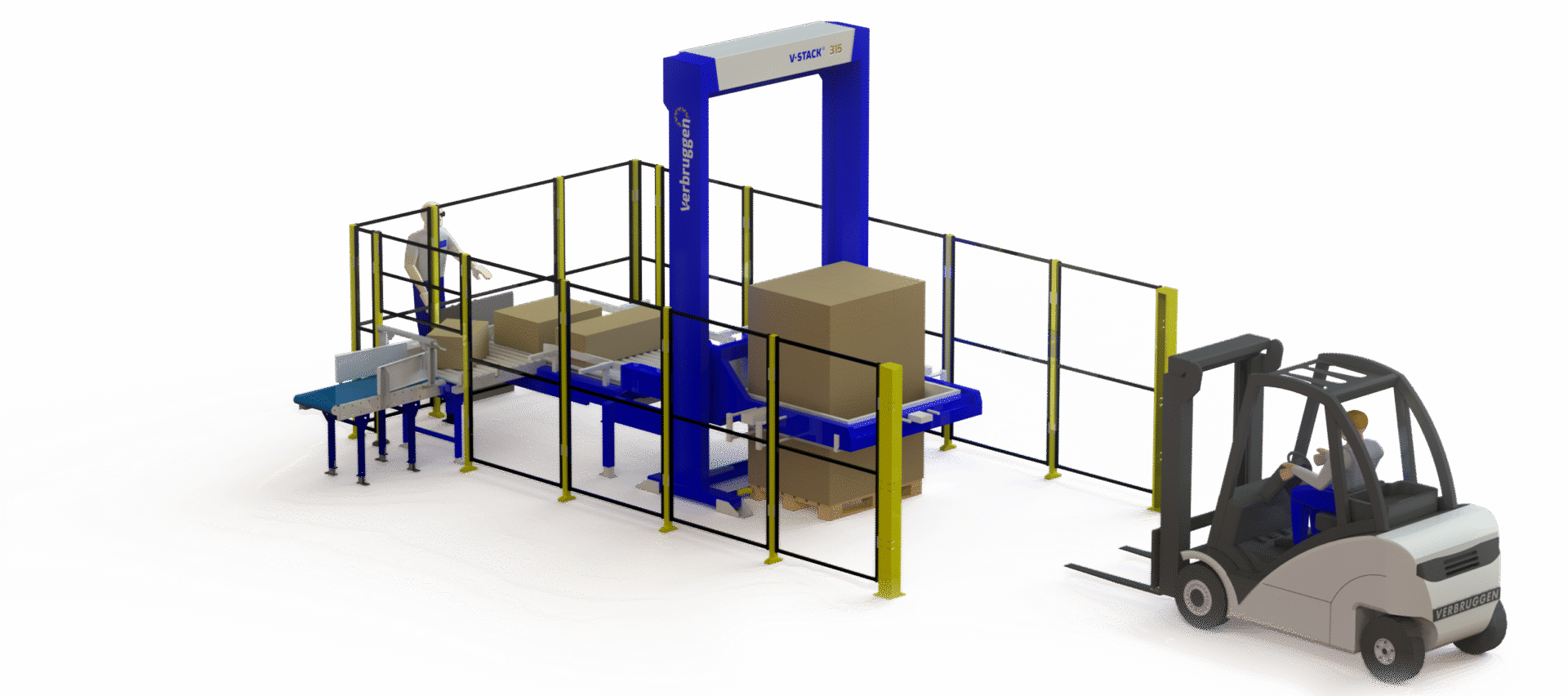

Overview Palletizing Machines

Handling bags / boxes / cartons / crates / wraps

Handling bags / boxes / cartons / crates / wraps

Handling bags / boxes / cartons / crates / wraps

Handling bags / boxes / cartons / crates / wraps

Handling bags

Handling boxes / cartons / crates / wraps

Handling boxes / cartons / crates / wraps

Handling boxes / cartons / crates / wraps

Handling boxes / cartons / crates / wraps

Handling boxes / cartons / crates / wraps

Product Information Notice. This brochure is for informational purposes only. Verbruggen Palletizing Solutions reserves the right to change product specifications, designs, and features without prior notice. Machine capacity and performance may vary depending on product type and specific application. For the latest details, please contact our sales team. No rights can be derived from the information provided.

More Information?