Let's get in touch

Email us Call usCall me back

Our terms and conditions will apply.

Let's get in touch

Email us Call usOur terms and conditions will apply.

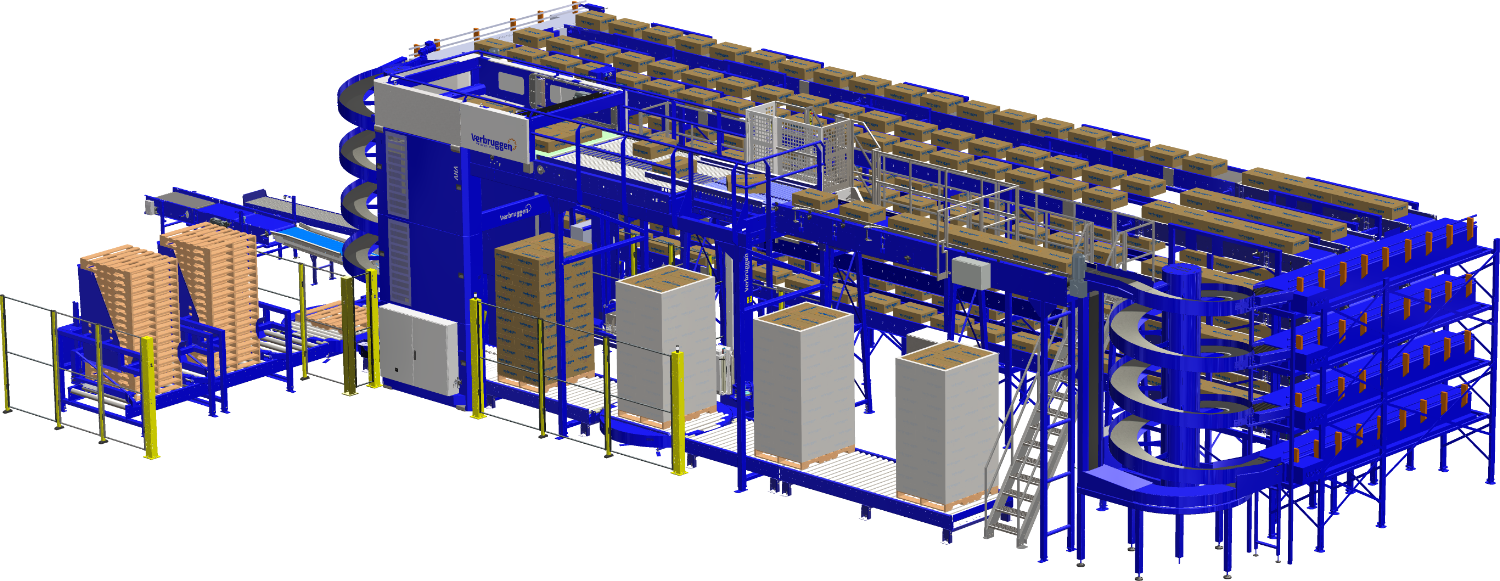

How to palletize boxes next level?

In collaboration with Intralox

GPOD of Idaho is a major high quality potato (Russet Burbank) handler and distributor in the US. The Russet Burbank consistently has the highest amounts of solids, making it the best potato on the market. It fries, mashes, and bakes lighter and fluffier than any other potato variety. GPOD keeps all production and shipping under one roof to ensure quality and provide you with a superior product.

Like many companies, GPOD of Idaho struggled with labour shortages at the back end of the logistical process of its plant. Particularly, staff were unwilling to manually stack product boxes of 22.7Kg (50lbs) for entire shifts. GPOD needed a solution to automate its palletizing line and increase accumulation capacity. Alleviating the workload for employees and improving the efficiency of its line. Based on GPOD’s defined needs, a system capable of palletizing 26 boxes per minute was required.

Let’s say palletizing potato boxes next level. That is where Verbruggen and Intralox came in.

” This technology is leaps and bounds from the other systems we looked at. “

Verbruggen Palletizing Solutions built that solution for GPOD, delivering a powerful logistical capacity with its VHV palletizer. The VHV offers the latest in technological innovations, fast stacking capacities and very accurate product stacking results. The VHV palletizer can be customized and expanded to suit the customers’ needs including multiple lines of product accumulation, pallet wrapping or corner board/strapping with fully automatic operation for optimum efficiency and cost savings.

80 – 120 cartons/boxes per minute

100 x 100 x 50 – 600 x 400 x 250 mm

Freely adjustable

User friendly touchscreen interface

Low

To be able to keep up with this high-level output, Verbruggen Palletizing Solutions brought on Intralox automation experts into the conversation early. The long-standing partnership between Verbruggen and Intralox helped to redesign and innovate the GPOD accumulation capacity. This partnership implemented the following products into the GPOD line:

Together with Intralox, Verbruggen Sales Engineering was able to deliver an ideal solution. The equipment, services, and training provided by Verbruggen & Partners achieve the goal of delivering 26 boxes per minute to a modern palletizer solution. Additionally, the entire system stands ready to be easily upgraded to a capacity of up to 40 boxes a minute. GPOD now has 100% control of the product flow, with an automated system. Crucially however, GPOD was able to reassign (and save!) the value of $320 000/year to less manually intensive positions

Industry leader in Palletizing Solutions. Dutch designed & built. Available worldwide.